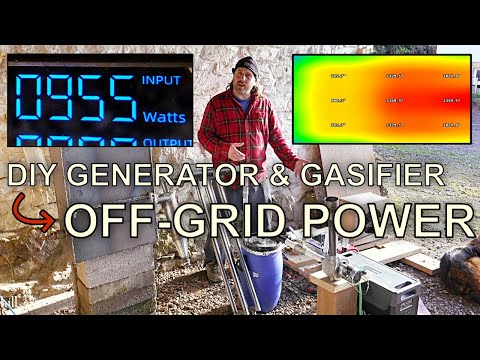

I am impressed with the quality of his build.

Ive been talking with him about this project and helping him. Gonna have to hire him to do my videos. lol

As I watch the video, he mentions you in the video ![]()

Ive become the student watching that. That really is excellence. What he shows with that controller are to the T what Ive done with the CXF-Si without even kinowing I was doing that. So now Im even more enthusiastic about building and testing that machine. I think its going to be a game changer.

800 + watts out of an engine is an extreme game changer… I would think dumping into an mppt charge controller to battery might be a better idea instead of that nice solar generator… I love the simplicity of the build, and think he should be routing the exaugh of the engine back in to gasifier to cool down the reaction.

So much to love about this systematic build.

thats what the steam is for. It cuts the oxygen. We want that overhead, we can cram more steam into the machines. We are not even touching the surface yet.

But… perhaps the reaction does not have to be cooled down as he is using firebrick on the inside of his gasifier… maybe hotter is better to produce more hydrogen.

Yes exaclty and why I added insulation for the first time. Not only that yeah very expensive insulation at that. ![]() We are going to be adding more too. There will be an additional water evap loop added to pre convert water to steam. Might not even need to build the chambered nozzle with this new water loop.

We are going to be adding more too. There will be an additional water evap loop added to pre convert water to steam. Might not even need to build the chambered nozzle with this new water loop.

Hi Matt, the charcoal and ash is very good for holding heat in and insulating too. I used ceramic wool for my insulating my double flute gasifier with stainless steel sides.

Flashing the water to steam is great and it works great on my system. The extra water runs out of my nozzles intake openings.

I was looking a your stainless steel nozzle build. If you put to much water in to it, it will cool down and flood out, adding water into your reaction zone. How about putting a extra hole on the intake side at the lower end of the washer of the nozzle. Then the extra water will run out if too much water is added. This will be come your sight monitor and will keep your water flashing into steam and not flood out the nozzle tube by it cooling it off to much. Not sure of how big of a hole would be needed though to do this. Maybe something to try on one of your nozzle testing.

this is why Im scrapping it. Going back to the simpler first designed versions. The evap tube should be more that enough to convert all the water introduced into the system. The steam will crash the unit long before it could be over whelmed with non coverted water. The insulation is to help raise the threshold to allow a lot more steam before the machine can be steam crashed. Plus capture and retain waste heat to put into the water loop and sustain core temps for process.

The nozzle worked without water pouring out but indeed you had to control the pump so that did not happen. I would never allow it to pour water out.

However the primary reason I am doing away with the chambered nozzle is because its not viable to manufacture. Stainless Steel destroys tooling and my little Lathe is just not up to the task. So I am reverting back to the simpler design and adding this water loop. Its a 6 foot section of stainless steel flex hose used for natrual gas appliances. Ive used these flex hoses before in early air preheat systems back in the day. I should be able to turn that water flow up quite a bit and that will solve the a new issue with the presure switch on those pumps. The last version is right on that threshold so Im confident it will be more than enough to get past that based on test performed last summer.

A quick note on that flex hose. Its corogated so that 6 foot section actually has a surface area of probably a 12 foot line. Plus it will slow the water flow as it will still be low voluem flow. So it wont stand a chance making it to the other end unconverted to steam

Yeah If I can get the pump to work consistantly due to higher water flow that is my primary goal. Ill be very happy just achieving that as this combined with the VersiFire my gross energy in verses net out is on par with a wood fuel gasifier if not better. The VersiFire is VERY efficient!

The secondary goal is finding the limits of how much steam I can introduce while sustaining the reactions without crashing. Im very confident I will achieve the primary goal and very optimistic how far we can really push this technology. This will be the machine that can actually do it. Its optimised in every way for its application.

Last year I was able to crack 5 liters per hopper load. Something like 14 lbs of charcoal per 10 lbs of water introduced into the system. This was all pure steam no water. When it was really cranking you cant even see the steam but you could see how it would pulse the glow inside the nozzle. It was really cool to see it workl.

Hello Mart,

Thank you for the video.

I also follow this gentleman’s videos.

He explains the details very well, using simple words, which makes it very easy to follow for someone like me who knows nothing about it.

Matt,

Here’s my feedback; it might help you understand some things.

Like many people here, you use complicated terms that are a bit daunting for someone who doesn’t know much about it.

I don’t want to criticize your technical vocabulary, as it demonstrates your advanced knowledge, but by using simpler language, you’ll reach a wider audience.

This desire to optimize water injection into the system is very interesting to me.

Keep in mind that the water also experiences turbulence and pressure loss (I’m currently improving the hydraulic performance of my turbine).

Since I don’t know the details of your system, I don’t know if these variables have an influence, but I just wanted to point them out.

I have no idea I have that or where it came from. Even my english teacher mentioned this when I was in college. I didnt excell here when I was in high school just opposite. But thats how I speak Im not sure I know how to relay words any differently. I make a lot of typos because I had to re wire my brain to do some things left handed due to a broken finger. Now it effects my typing

It was just a suggestion for improvement, but for me, it’s great the way you’re doing it; you’re taking the time to make videos for others, and that’s already really kind and courageous of you.

Funny thing is. This broken finger was on my left fretting hand as Im a guitarist. When I broke that finger and it didnt heal straight I could no longer play. That is devistating to a guitarist. Well turns out that was a blessing. Within 3 years re learning to play lefty I well exceeded 35 years of playing guitar. I was not able to play solos. I can play almost all the solos from Rush and earlly Black Sabbath now. lol

Ah great, a post in the workshop music topic is definitely in order!

in the video you can see how important is a sufficient lenght of the reduction area for making good gas…it is not a question of nozzle protruding how he think…more or less nozzle protruding helps only to protect the hopper wall from heat…more lenght of reduction area, more bigger ccm motor can run

Yup thats why have a double wall to adjust the nozzle length per the applicaiton. You can visually see where the consumption is after a hopper burn. I try to adjust so its centered for better fuel consumption of the hopper. Also why I run smaller diameter nozzles to penetrate further and get the heat away from the nozzle and front wall.

Reprogramming my brain to be able to fret right handed is beyond my comprehension. Left handed fret work is just about all my left hand is good for. I doubt I could even hold a pick with it.