Hello everyone,

To start, a brief introduction: my name is David, I’m 34 years old, and I live in Belgium.

My native language is French, I use a translator to understand and speak to you, even though I have a basic knowledge of English (I apologize in advance for any translation errors).

My well has always provided me with water, and I recently had it treated to make it potable.

Just like with water, I’d like to become self-sufficient in electricity production.

I currently produce electricity with photovoltaic panels (12.3 kWp), two pico-hydro turbines (350W x2), and a diesel generator (14kva).

For storage, I have batteries (40 kW lithium).

For management, I have an inverter with backup power and home automation throughout the property (almost, as I’m currently renovating).

I am short approximately 1000kW per year, which I need to produce with the generator.

I’d like to use a gasifier as an alternative to my current generator because I own a woodlot and would like to utilize this resource.

Furthermore, I love chopping wood; it’s very relaxing for me.

Just to clarify, the wood-burning stove will be stationary and will run on wood. After doing some research, I prefer wood to charcoal.

I would like the fuel to consist of wood chips of varying sizes to minimize waste.

The wood chips will be produced in the summer when solar power is plentiful.

The types of wood are varied (European oak, birch, spruce, etc.).

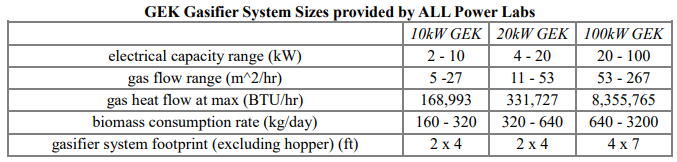

The engine used will be a 4-cylinder engine from a small car (fairly easy to find around here). I would like the electrical output to be 10 kW/h and to last approximately 3 hours without intervention.

Recovering heat from the gasifier also seems preferable to avoid waste.

I hope I’m not being too demanding; if so, please don’t hesitate to let me know. I’m not one to give up easily.

I don’t want to revolutionize the world of gasifiers, but I’m simply looking for the best alternative for my personal situation, and I hope you will be willing to help me with my project.