Kristjan , hvala za objavo in lepo predstavitev, morada bo komu koristilo.

Še moja razlaga:

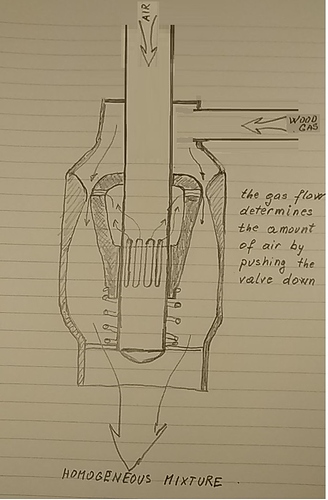

Želja je bila doseči, od prostega teka motorja (ko je pretok zraka najmanjši in je potrebno zelo fino dozirati plin), do polne obremenitve, kaj se da enakomerno mešanico gorivo zrak (1:16 ).

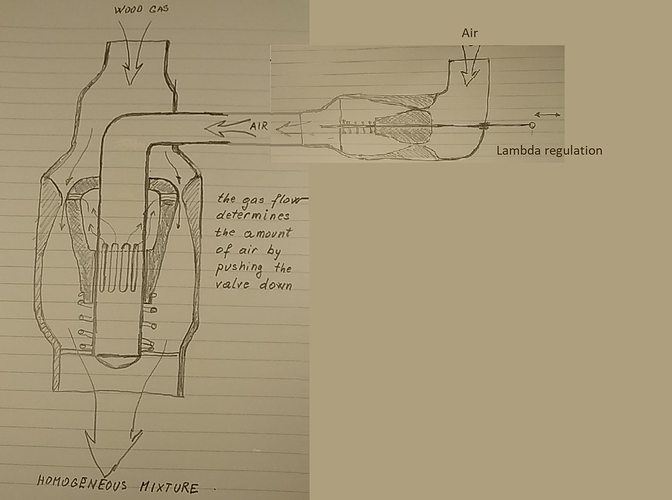

Osnova je venturi cev , v kateri sredini se nahaja gibajoč se element , ki ga pretok zraka potiska s seboj, tako presek pretočnega dela spreminja, hkrati pa tale gibajoč del deluje kot ventil , saj na cevki , po kateri drsi odpira večji ali manjši presek tudi plinu (izvrtine v cevki).

Sistem je popolnoma mehanski,od elektrike je edino preklopno stikalo, s katerim preklapljam tok iz bencinske črpalke na mag, ventile plina. Sedaj ko je izdelana geometrija in izvrtane primerne luknjice se dejansko nima kaj pokvarit ali “razštelat”, …

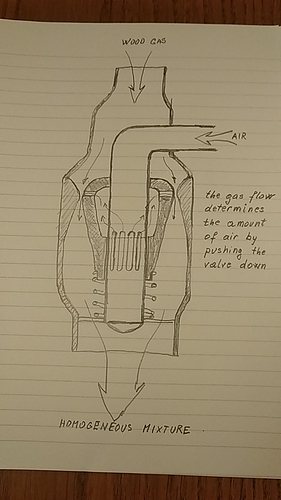

Podoben mešalnik imam v prihodnosti izdelat za lesni plin le da bo razmerje 1:1 , sam mislim , da bo omogočal stabilno in homogeno gorljivo zmes v širokem območju delovanja motorja

Christian, thanks for the post and a nice introduction, it must be helpful to anyone.

Still my explanation:

The desire was to achieve, from idling the engine (when the air flow is minimal and the gas needs to be fine-tuned), to full load, giving a uniform mixture of fuel air (1:16).

The base is a venturi tube, in which center there is a moving element, which the air flow pushes with itself, thus changing the cross section of the flowing part, and at the same time this moving part acts as a valve, since on the tube through which the slide opens a larger or smaller cross section gas (holes in the tube).

The system is completely mechanical, with electricity being the only switching switch by which I switch the flow from gas station to mag, gas valves. Now that the geometry has been worked out and the holes drilled, there is actually nothing to spoil or “crack” …

I have a similar blender for wood gas in the future except that the ratio will be 1: 1, I think it will allow a stable and homogeneous combustible mixture in a wide range of engine operation