the nozzle, yet without egr / water or steam addition, builds up his own protection…no heat damage seen on the nozzle head…

yesterday in the evening another run…the horse harrow got 2 hooks more, and a box for stones for additional weight

Wonderful pic’s and build giorgio ![]()

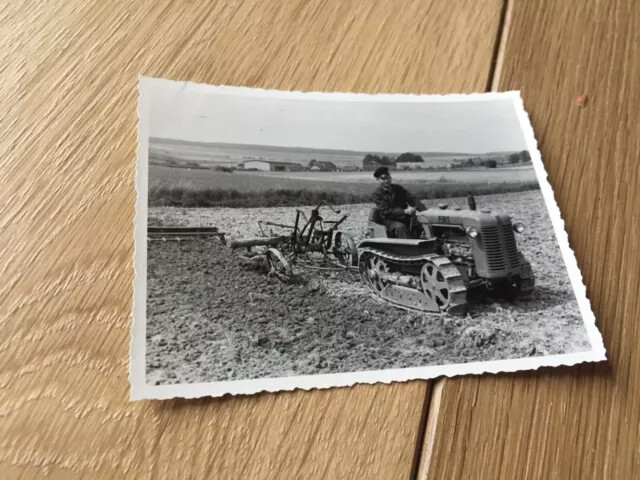

Heres an old pic showing how happy it makes one to farm with a charcoal powered crawler.

Recently there was a discussion about dosing water vapor into a charcoal gasifier, well, you use a bubbler to humidify and clean the gas, some time ago I did some calculations and came to the result that the ideal humidification of fresh would be provided by a bubbler heated with engine cooling water at 80°C.

I found this picture online, it was taken near my home after World War II,…

This is a very nice build Giorgio. It looks like the time spent designing a building this is going to pay off in the long run. Stainless should last a good long time.

You mentioned you used your battery stick welder for this project, but what did you use to clean the welds after? Did you just use a wire wheel or do you have some kind of chemical cleaner?

hello bronlin, normally i am hammering only the slags away, instead of a slag hammer i use the point of a file because of its hardness…only when seams become too coarse the angle grinder must help…the slags of ss are dangerous, because of the tension in the material, they can jump easily in your face, espescially welding even pieces, …the slag layer seems really to explode

here a picture of a former fiat model - picture got from göran- a fiat boghetto with 40 hp from around 1940, with our tractor model fiat aimed to small scale farmers…

the picture from tone above…the gasifier maybee self built?

are there further informations?

Giorgio, unfortunately there is no information about this tractor, the photo was taken by a postman, and the driver’s name was Vinko Sever, which is a common surname in our area.

If you look at the system in more detail, you can see that the gasifier is made of two parts, which means that the condensation zone is above (you can even see the condensate drain pipe), and below is the hot zone, it seems to be a fairly advanced gasifier. On the right side next to the driver, there is probably a filter (horizontal container), I think the radiator is horizontally mounted under the engine hood, maybe that’s why the upper part of the engine hood is open, the pipe also comes from above towards the gas mixer,…

This is just an opinion,…

I am not convinced that is a condensate drain pipe. It does look like one. I just don’t see much of anything for vertical support to keep it from bouncing around, and it seems like it would be top heavy.

It is a great picture. I love how they all have jackets on. ![]() I kind of wish they had a picture of the other side.

I kind of wish they had a picture of the other side.

Beautiful work giorgio, ![]() what does gearbox come from?

what does gearbox come from?

How did you make this beautiful fan? Do you have any other photos or explanations?

It’s a true work of art.

göran, and thierry,

the gearbox ( transmission 1: 34 turns) is from a old smith forge blower, i have presented around a year ago in the forum. the original housing has had a lot of splits , i tried to weld the cast iron, but is from the kind i have not the possibility to weld…so a new housing and a bit larger as the original was the solution, also because the rotor of the original was a bit poor of design, and probably less air was moved with the original. for a bigger rotor but was required a second ball bearing on the part where the air entering hole is.

good gears are to find also on old grinders with handcrank for knives or carpenter-joiner tools. they have often a transmission from 1: 21 around…the good ones are with 4 axles especially because they have a more thicker axle because they must carry the grinding stone…the gear from the forge blower i used has a very small axle of around 7 mm. this was ok for the original light rotor , but for the new one not. so i used this axle only as drive for the rotor, but the weight of the rotor itself lays on two ball bearings with 15 mm axle hole…

generally the design is so:the rotor is centered, the air transport channel around begins on the exit side at nearly zero, than becomes always wider and at the exit it has 5 cm seen from the outer circle of the rotor…

we like it not to be dependent of batteries

today we have mounted it on the crawler, but no time for trying it, because we must bring some horse manure to the field with the pasquali, of course with gasifier…and yes, in the morning we have had some fresh cold air, so we made quickly 200 liters of charcoal in the bathtub for warming a bit…