Beautiful creation Giorgio, that crawler will serve you well ![]()

for slag diminuition we added a water drip system…where the gas feeding pipe enters under the nozzle, i made the pipe double walled , hollow space 2 mm, there happens the steam production…

the bottle gots a hole with a glass drill at the original bottom, now top, for avoiding vacuum in the bottle…also refilling works well there because the drill is 10 mm

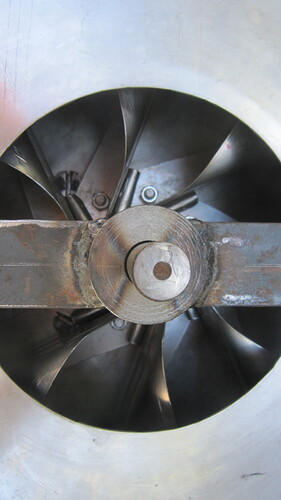

my son discovered that the blower throws out some air at the air suction hole, so we cutted the blades again a bit in the center area, on the foto it shows the actual shape, and then a test with smoke for to see the air stream…

looking at the construction of my other blowers, i would say generally that the space where the air is sucked in should have a more or less conical shaped space around the axle

Just a few thoughts on the design of a coal gasifier:

- a nozzle at the bottom and an upward gas flow, as you can see, causes the least thermal load on the nozzle, since the heat rises upwards, the gas outlet at the side is a good solution, this way you allow some of the moist gases to be retained under the hood and have the opportunity to descend along the wall to the hot zone

- a transverse process is probably optimal for a coal gasifier, this is also noted by Matt. Air is supplied from one side, in the middle there is a hot zone, where most of the fuel is consumed, the ash falls down through the grate, the gases are sucked out on the other side, the steam has the opportunity to retreat upwards and return along the wall to the hot zone,…

Giorgio, you have built a good system, may it serve you well. ![]()

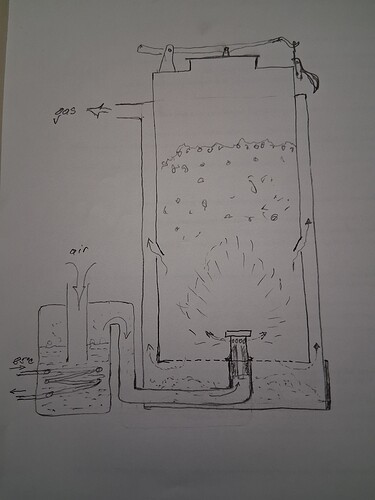

Last time I wrote something about a charcoal gasifier, and now I’m attaching a sketch of how I imagine the construction.

A nozzle with side holes at the bottom in the middle, so that the heat is also distributed in width.

The bottom is also an ash grate.

Air humidification with water heated to 80°C.

The gas is partially sucked down through the grate, and partially sideways through higher openings.

The gas travels through the space between the outer shell and the inner container, here the gas cools and the gas flow is slow, most of the ash falls down into the ash space.

interesting design, tone, is it for your forklift? must the incoming air goes through the water, or is it enough when the air goes over the water to absorb umidity?

about air umidity…old ford or fordson tractors here in old times have had not so much power during the day because of the very hot temperatures…instead in early morning or night they run well…so they lead the incoming air for motor combustion through a tank partially filled with water in way that the air must stream narrow the water , and power was good than…

back to your design, the low gas outlets are good in way that the coal in the hopper above gets not so much heat.

the nozzle is interesting, glowing coal has not direct contact with the air holes because of the kind of roof above, air umidity cools the nozzleand the holes should not get blocked or lowered in diameter…the double wall maybee not requires a cooler and also no cyclon , what would also not work with low speed…the double wall but makes maybee a bit more weight or also not, but i would add a cleaning port also located over the grate, going through the double wall, for easy slag removing or complete emptying…

we tried now the water dripper and the amount of slag is reduced drastically, but we noticed no additional power with water dripping, not to hear more rpm when dripping…i think our coal is very good because of standing only short time in the heat when making…

we let a opening for a eventual water cooled nozzle or igniting a half full or full hopper from outside…as i have a pulling, but not sucking system, it was interesting if it works for starting, and yes, it can be done, igniting the coal from outside with a bit alcohol and a bit blower wind makes a nice strong glow, what is needed to push with a thick rod in direction to the nozzle, than closing the opening, giving wind with the blower( first time i tried this)…the start is very simple so without having a propane torch

another experiment we made with 3 times used coal after a test run we tried a restart in the evening with the same coal, the flare was only a nice blue color, nothing orange as usually with fresh coal

than we opened the water dripper for to see what happens…after a while the flame becomes orange again as normally is, because of the hydrogen from the water drops

stopped the dripper, the flare becomes blue again, only carbon monoxyde, because the coal has had no hydrogen more because of the 3 times of using

Thanks Giorgio for the comprehensive comment and explanation, it is interesting to see the pictures showing the difference

of the flame between supplying moist and dry air.

A small forklift is a very good helper when working on a farm, well, it mostly works for a short time, which requires a quick start and a quick stop, and for this the charcoal gasifier has a great advantage over the wood gasifier. I also intend to use it to drive a wood splitter, but then it would work for a longer time.

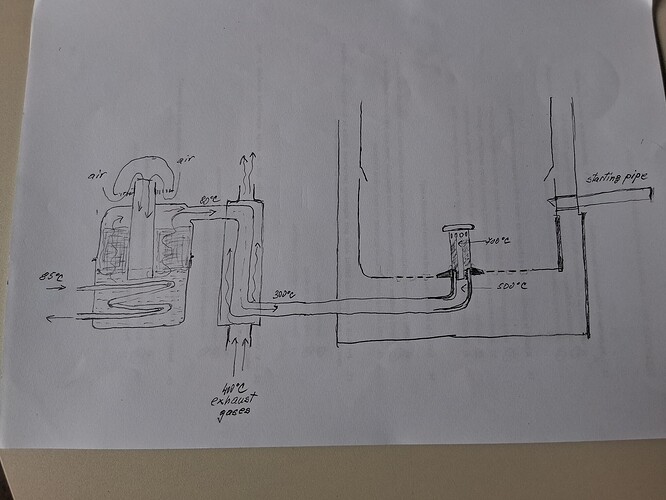

The heating and humidification of the supply air would take place in a heated container with water, practically this would be a larger oil filter with a metal sponge, in fact this would happen in a water bath. The air is thus heated and humidified to 100%rh, at 80°C it contains 290 g of water per kg of dry air, (at 60°C it would contain 130 g). 290 g of water per kg of air will be, according to my calculations, quite close to the ideal ratio for good gas. It is good to additionally heat such saturated air to prevent condensation, for which I intend to use an exhaust gas exchanger,…

the disadvantage of coal gasifier is only that hearth cleaning must be done often, also after every longer use (some hours) therefore a cleaning port wich gives easy access to the hearth,

a shaker works for a limited range only in sight of cleaning, you cannot clean out the complete hearth wit it, because more you shake, also more coal becomes powder…easiest dump down the used coal, store it somewhere, and when the quantity is more, sieving all together, with a effective sieve like my drum sieve.

a gasifier like your design with low speed of gas because of the large gas exit surface is also less self cleaning as a speedy construction, what drags out the dust from the hearth in the system,

at a recent test run on the field under load we were to lazy to use new sieved coal, so we used the dusty coal from the last run, but after a while we have had problems with the power, the motor suffers and i must limite a lot secondary air because of the big resistance…this was when i have had only one gas exit…there was a lot of amoun of slags and dust that blocks the hearth…this was before using the water dripper, withthe dripper i expect a lot less slag because of a cooler hearth temperature.

generally we see no problem with moisture in the hopper because our coal storage is good and dry, eventually at starting there is a bit of moisture on the inner part of the lid, what can come also from seasonally air moisture, but afer 20 minutes this moisture disappears completely, oservation on my downdraft systems without steam addition or water drip.

my nozzle on the updraft gasifier on the fiat must not be the ultimate design, it was the easiest for first trying, now observing cosumption, further it is made from a simple thick steel piece and not from inox stainless steel…maybee i will change in future in a nozzle with 2 exits on the side for distribute more the consumption funnel in the coal, now centered, to both sides for a longer theoretical running time…also little pieces cannot fall in the nozzle than, what but with the actually design is also not a problem, i have in direct line under the nozzle a cleaning opening like eddy ramos has

Where does the coil in the water bath container receive it’s heat from?

Tom, the engine has a thermostat that maintains approximately 85 °C in the block and engine head during operation, this water is intended for preheating and humidification with