tone, if i understand right, you will produce air with maximal satured umidity, like fog - right?

than with the exhaust system you produce steam from this maximal umid air…

where you see advantage or disadvantage to a water drip system?

the dripper must be regulated , your system not i think…are there further advantages?

Tone, I see the lighting starting pipe on the side of the double wall gasifier, might be hard to have a air tight seal on the walls . How about going up from the botton with a T below the nozzle and light it from there. It can also be used as a clean out if any ash gets into the nozzle holes and nozzle holes clean out. With a theaded cap.

When talking about humidity in the air, there are two different terms, relative humidity and absolute humidity.

Absolute humidity means how much water vapor (water) is present in 1 kg of dry air.

Relative humidity is expressed in % (from 0 - 100%), well, relative means “depending on”, here it depends on the temperature. I gave an example above:

- air with a temperature of 80°C can contain 290 g of water vapor at 100% relative humidity

- air with a temperature of 60°C at 100% Rh can accommodate 130g of water vapor

Water vapor is a gas, when water changes its state from liquid to gaseous, it requires 2260 kJ per 1 kg, which is 0.63 kWh. (for illustration, if we heat water from 20 to 80°C we use 0.07 kWh, and for heating air we use 0.017 kWh). If the humid air starts to cool and lose heat, the water vapor starts to liquefy in the form of tiny droplets - fog, this is already the liquid phase of water and not a gas.

My intention is to heat and humidify fresh air with the “waste” heat of the engine, here the energy savings per 1 kg of charcoal used would be: - heating and humidifying air from 20 to 80°C … 0.5 kWh

- heating humid air from 80 to 300°C 0.2 kWh

and still about 0.35 kWh is spent on cooling the nozzle when the air is heated from 300 to 700°C.

If I summarize now:

-we have 1kg of charcoal with an energy value of 8 kWh

-when preparing the air (humidification, preheating) we can save about 10% of this energy or 0.7 kWh

The nozzle still remains cooled, and we return this energy directly to the process and nothing is lost

-the less heat we lose, the better the gas will be and even more water vapor can be converted into H2

Here I made an example with 0.6 l of water per 1 kg of charcoal, and Matt is aiming for an amount of 1 kg or even more, in which case the savings would be 20%, or, without preheating and humidifying with an external heat source, it is probably not possible to convert such a quantity of water from 1 kg of charcoal.

Hi Tone

I love your sketches; they’re always very informative.

How do you know that the temperature of the air/steam flowing through the inlet pipe reaches 500 and 700°C at the nozzle? Is this a guess or a calculation?

Thierry, the reactions in the hot zone take place in the range of 800°C to 1200°C (this data is given by all sources that deal with gasifiers), if we install a nozzle that extends 10 cm into this hot zone, its surface will heat up to at least 800°C (probably even to 1000°C), and the thick metal of the pipe transfers the heat to the lower part, well, if I take into account the speed and inlet temperature of the humid air, I can estimate (or calculate) the final temperature, which will be approximately 200-300°C lower than the surface of the pipe. We must imagine that these temperatures fluctuate depending on the load, I only state the temperatures that are present at “normal” load.

This must of been above normal than Tone. Driving my 92 Dodge Dakota I have see temps. at 1600 °f or 811.111degrees celsius or even higher. . My temp. prob is just above the grate. I noticed when my temps. are higher than 1400 degrees f or 760 degrees celsius I have the best wood gases to run my 5.2 engiene. I know one thing for sure every gasifiier is different from the building it to how it runs making good gases. I like your theory on how it should work by the math of numbers. Real life gasification seems to differ at times.

I must not burden Giorgi’s topic too much, well, let me just think a few thoughts…

In a university thesis I found online, where the guy discussed gasifiers, he wrote down certain measurements, stating that temperatures can rise up to 1500 ° C, if there is a turbulent air injection between glowing charcoal, the guy also states a typical ratio between water vapor and air per 1 kg of charcoal, which is:

-water vapor 0.5- 1.2 kg

-air 0.8-1.5 kg (m3)

theoretical maximum ratio is:

-water vapor 1.2 - 1.5 kg

- air 0.4 - 0.8 kg

- temperature 900 - 1000 ° C

If I try to comment on these numbers:

if we manage to keep the temperature between 900 and 1000 in the core of the gasifier °C, while preparing the superheated humid air to the theoretical same temperature with an external heat-energy source, without pumping and then returning heat from the process, we can produce gas with 0.4 kg of air and 1.5 kg of water, this would be a very calorific gas with a lot of hydrogen and a little nitrogen, probably quite close to natural gas in terms of power.

I am also thinking about the construction of a nozzle or a ring of nozzles for air supply,… one nozzle represents less surface area for removing heat from the heart of the process but is exposed to more concentrated heating, well, with more openings to the outside, the heat is distributed a little more on the surface, and the fuel collapses more evenly,…

All comments are welcome…

professor tone, no problem, please remain with this discussion on the fiat topic, it is very interesting, also because my brain till now not goes so far…but with time can happen

especially for the charcoalers here the discussion is interesting…

the umidity ( or egr also in my gasifiers) keeps temperature lower, it is to see on the more or less slag and their consistence…your thought is to keep the temperature between 900 and 1000, where umidity help to achieve this goal…but when you preheat so strong the incoming air, will the temperature in the core also raise higher?

sice i have the waterdrip i found condensation water after the cooler and in the traverse basement pipe…will say all the water is not transformed, when i see it right?

Thanks Giorgio, you have highlighted a good indicator of sufficient water content - gas humidity. How should I answer the question of whether superheated air will raise the core temperature?

-Yes, if the proportion of oxygen in the water vapor/air mixture is high, then the intensity of oxidation will increase and thus the temperature in the core.

-No, if we increase the proportion of water vapor, since the reaction of decomposition of water vapor into oxygen and hydrogen is endothermic and consumes the heat of the core.

I will list some more properties of water vapor and humid air:

-air with a relative humidity of 100% at 80°C contains 300 g of water vapor, and at 100°C it contains twice as much - 600g

- 600g of water vapor has a volume of 1m3, which is the same as 1kg of air

These characteristics show that with a relatively small change in temperature, the ratio between steam and air changes quickly, which is good for controlling the core temperature. Horsehair is used to measure relative humidity, it could also be used to regulate the process. It would be necessary to install a bundle of horsehair in the pipe after the refrigerator, where it would be in the gas flow. If the gas became more humid, it would close the valve for heating the water, but if the gas became drier, the valve would open more,…

Giorgio, the temperature will not go higher, but more of the water you now get in your gas will be turning in to hydrogen and the gas will be less diluted with nitrogen.

Theoreticly it is possible to get gas only by injecting superhot steam over carbon, without any air and thus without nitrogen (gas 100% stronger as you got now!) but heating the steam that hot isnt practical or economical.

But any energy input helps!

Good to hear from you Kristijan. What is going on with you lately? Inquiring minds want to know. ![]()

in practice we can only add a limited quantity of umidity-water for not to cool down too much the hearth…this quantity can be higher if we transform the water in steam -or produce air with maximal umidity , than heated up more with exhaust heat , how tone suggested. so we can bring more water inside without cooling the hearth critically…if than the nozzle becomes too hot, would be only a little problem what can be resolved with a water cooled nozzle .

the water reservoir must not be very big, what i can see on my pasquali, the water loss caused of evaporation is not much, only some centimeters in height during some hours of run…of course serve some liters of quantity of water in the water tank to keep up the mixing and therefore cooling down effect

Now that we have already “deeply” entered the conversation about the charcoal gasifier, it is good to continue, because the thoughts are fresh,…

Let’s try to imagine an area with glowing charcoal, in the middle, surrounded by “insulation” of the rest of the charcoal, into this area we supply superheated air with a large proportion of superheated water vapor,… we have already found that the nozzle installed below is the least temperature-exposed, since the heat forces upwards, so it also takes the least energy from the process. The nozzle installed below is also quickly surrounded by ash, so the energy transfer is even smaller. Here I come to an important question, is one nozzle in the middle enough, or is it a better choice to install several smaller nozzles below in a ring of about 10-20 cm in diameter? If we try to imagine the shape of the glowing zone that is created, I can say that one nozzle with one opening creates an elongated shape, similar to a candle flame, which can reach quite high. If there is a ring of nozzles below, then a shape is created, like a flame on a gas stove, well, in this case too the temperature is concentrated in the middle, but I imagine that the shape is more spherical, which is better for the process. However, it is necessary to make a double bottom on which to place the nozzles, a double bottom also means good preheating of the air, as well as cooling from the nozzles.

Interesting discussion this is. And what about that guy that build that simple crossfire. Can find who posted that video. That was interesting too. He found out that the gasifier had a condensed bottom, lengthened the nozzle and the gas was ok. What about that? Can one of the doctors explain? Charcoal is very tempting… Could it be true that the waterdrip compensates for the preprocessing char making?

[quote=“Tone Šuštarič, post:74, topic:8302, username:Tone”]

one nozzle with one opening creates an elongated shape, similar to a candle flame, which can reach quite high.

If the central nozzle has several small holes directed horizontally, wouldn’t the combustion area be similar to that of a ring of nozzles?

The thermal radiation from a low nozzle is partially lost, carried away by the synthesis gases. With a high nozzle, the radiation contributes to heating the fuel.

Did I understand correctly? ![]()

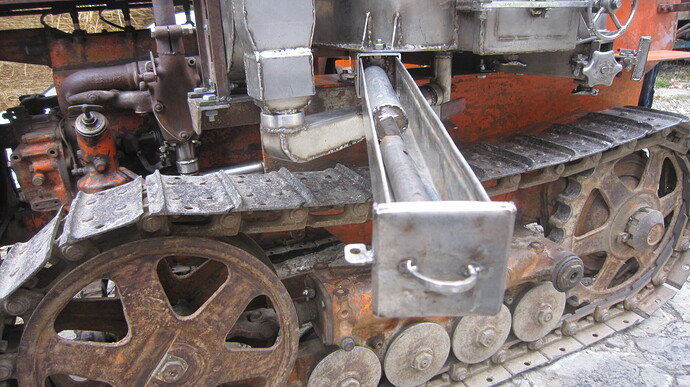

tool box , the pipe is closed on both ends, is used for push the glow over the nozzle when igniting the hopper from outside

today we brought the gas exits in higher position, because deep as they were they made a ostacle for the coal sliding to the center…after 2 hours refueling was required therefore…instead of run with only one exit it runs more than 2 hours and 40 minutes

generally can be observed that the coal - also in my other builds become a solid layer in the hopper about of vibrations…this can be a benefit when doing cleanout. if it is done careful only the coal what is full of ash can be raked out, the other more cleaner coal remains like a dome in the hopper, especially when the diameter of the hopper is round and not to large…helpful for this effect is also a kind of restriction in way like tone has designed, where he makes the circuit space for gas exit. the cleaner coal than can be reused for next start without taking it out…only igniting from outside is than required, because the coal covers more deeply the nozzle…maybee this observation is useful for tones forklift, what runs only for shorter times…so quick restart can achieved

How many CC engine is that and how many rpm? At that rate it could power a small car for quite a few miles or kilometers. Old men would have to pee before the fuel runs out. ![]()

cc is 2250 and rpm 1900 max, when i remember right

on the hooke the original with gasoline has 21 hp, with kerosene 18 hp…with coal gas i dont know, but seems not weak