Dave,

Please remind me. What are you using for a filter before the Dyson cyclone?

I have the gas outlet on top of the 55 gallon drum from there it goes to a fire extinguisher cyclone and then into a 8 inch dia pipe that is about 3ft tall filled with lambs wool and foam filters and then onto a small inline pool filter and or the Dyson filter before the engine .

Hello Trigaux,

The cyclone’s sides slow down the particulate matter by

gravity/friction and that matter spirals down to a removable/ cleanable

collection reservoir at the bottom (as the gas is exited at the top of the cyclone).

Mine is a 1 1/2" screw top 2 quart metal container that screws onto the bottom

of the threaded cyclone. I built to the specs for a 35 HP engine on the imbert chart.

The thing works great removing huge amounts of particulate matter and gives me clean

burning gas. It takes up some space, but you’re looking for quality clean gas, right.

OK, that’s one vote for the single larger cyclone. Checkout “My first small engine run”

in the Small engine section for my cyclone.

Dave,

Cyclone followed by lambs wool and foam filters sounds great. Do you have any observations or opinions about how much wool, what kind of foam and what order you think works best? Are there ever any moisture issues?

We on DOW are so blessed to learn from your experience with so many hours of real world useful work from gasifiers.

Bruce ,

I bought 3 pieces of wool 20 inches by 40 and 3 inch’s thick that someone was advertising as insulation its like carded lambs wool its really fine and so i just stuff as much into the tube to make it as hard as possible for larger particles to get past and then a 4 inch open cell foam circle on top , i do it in that order mainly to stop any loose strands of wool being sucked further up stream .

Moisture is something i don’t seem to be able to control with how i have my setup due to many factors , we have a humidity of 97% today and so i guess my charcoal will soak a fair amount of that up and give me wet filters at the end of the day , other times its bone dry , living in the clouds can be fun .

I forgot to close the air valve on the gasifier after cleaning out the build up around the nozzle the other day and so my drum full of charcoal was popping away when i lit it yesterday ,and what i noticed was a very weak lack luster flame when flaring off , but if i stopped the fan and allowed it to just sit for a few mins as soon as i started the fan i got a roaring blue flame and i do mean roaring for about a 40 seconds and then back to a lack luster type of flame , that continued for about 10 mins till all of a sudden a good roaring flare stayed on , i guess my then i had managed to dry out most the charcoal in my drum .

Thank you! This is the kind of excellent and priceless info that helps those of us that don’t have your many hours of hands on experience under a wide range of conditions.

I was inspired by this video ,https://www.youtube.com/watch?v=665tpfoU3yQ 30, that Koen has mi on driveonwood

back of the oven

steam evacuation chimney

pyrolysis gas on fire in the oven

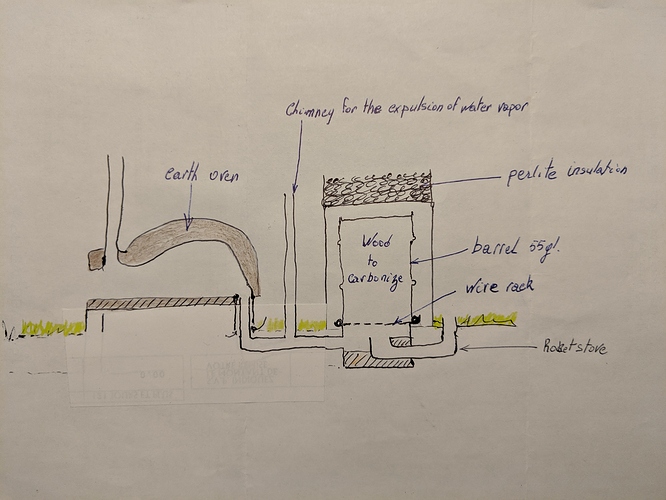

“artistic” schemas of the system

the first carbonization was not complete (incompletely charred wood ).I sealed the rocket stove as soon as the gas is ignited in the oven. will I have to let in a little oxygen for the pyrolysis to be complete?

Thierry

When the flames from the burning volatiles die down, then seal the rocket stove.

Maybe allow the moisture and pyrolysis gas to come out of the top of the 55 gallon drum and down to the oven passage instead of from under the wire rack/grate.

Good idea for captureing some waste heat!

Thanks for the Bruce suggestion

I, too, think that the evacuation of

the water vapor will be more efficient from the top than from the bottom

I am a little surprised by the little energy released by the pyrolysis of a wooden barrel!

The oven would never come hot enough to cook only with this barrel

how can we calculate the potentially recoverable energy of wood pyrolysis?

Thierry

I think one of the reasons (in the video) they gave a long path to the barrel exhaust was to capture and use the distilled products, wood vinegar and tar. Thanks for sharing this, Thierry, I really like your ideas!

I did a new test at the end of the week

I had a better fire in the earthen oven

when the gas went out by itself, I sealed the barrel of coal (as Bruse recommended to me). At this moment the smoke came out but did not burn anymore

I found very little non-carbonized wood. Coal is denser than the coal I make in my TLUD

The condensed tar on the barrel sheet falls into dust. I have to deduce that the coal is ok ?

Thierry

Don’t know for sure, but one test is to crumble the charcoal in your hand, it should crumble and the dust not stain your hands, it should be dry and brush off easily. You can also burn some and check the flame color, should burn clean with no or not much smoke, no orange flames of volatiles still burning. Do the pieces ring when jumbled together? that is a good sign. Others may have a better idea!

here is a video of the gas burning in the bottom of the oven.

the embers ahead come from the fire that I had lit previously in the oven

I’ll post more videos later when inter net will work better

I like it, that looks very viable. It is similar to the old Ukrainian ovens that settlers built to the north of here. The combination with a barrel retort would produce a lot of char over a year if fired every few days for bread, etc.

I make between 25 too 50 litres of charcoal everyday during winter and it all comes from my slow combustion wood heater , the charcoal i use for my generators and never have i had any that would ring when banged together , it is all very light in weight and crunchy , when i use the indirect method during the spring and early summer outdoors burning the small branches and what ever needs cleaning up , does ring when banged together and it also feels a lot denser and heavier , but still burns clean with no tar issues at all , but my hands get much dirtier and harder to clean from it than with my indoor stuff .

Dave

Hi Dave

Do you perceive a difference, with your gasifier, between the types of coal? (direct cooking charcoal and indirect cooking charcoal)

No difference what so ever power wise and, start ups are the same even the run times roughly the same when i cook my steak on BBQ they taste the same on both types , like i said the only difference is that the indirect charcoal has a lot more black carbon dust and is much harder to wash off hands .

BTW if you tend to get very messy when preparing your charcoal rub a little Vaseline in your hands or around your eyes or where ever you tend to get dirty that will help to just wipe the carbon off you before washing with soap and water .

Dave

I remember a conversation between Koen and Garry Gilmore about it. I do not know which place on the forum. I remembered that the indirect method was longer and produced a coal, more reactive and richer in H2 (hardly noticeable, no doubt)

Thierry