So the hunt for parts goes on.

I want an idle control board, but I got a quote of 107 USD plus shipping ( and god knows what else happens )

This looks like 150 or more Canadian by the time the dust clears.

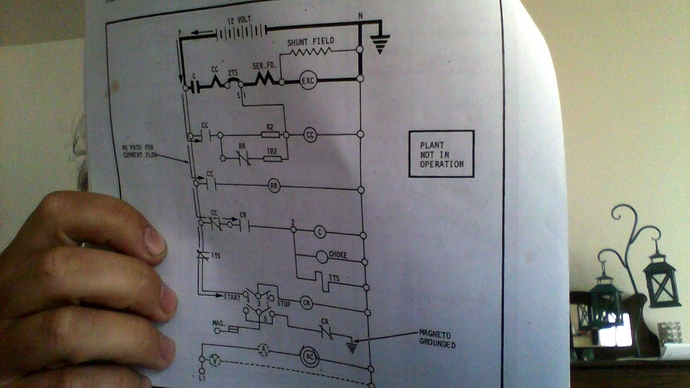

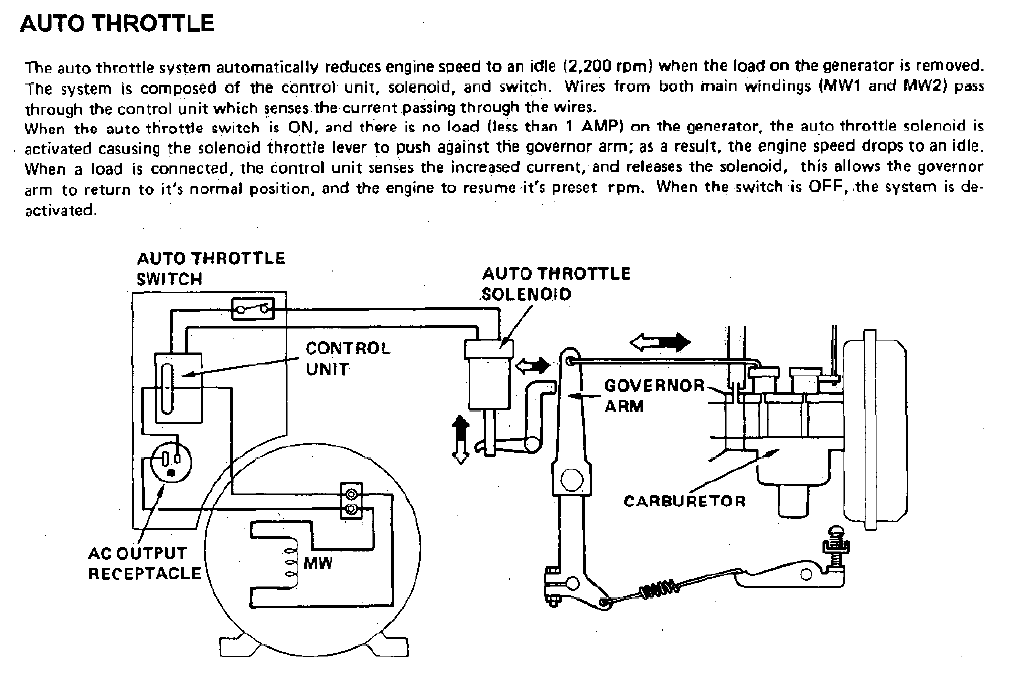

But this is what I want the board to do.

And I am not apposed to making one out of spare parts.

In for a Penny in for a pound I think the smartest thing to do is build my own ECM around this problem and add some electronics compliments of the Arduino project.

I still need an airfilter.

Now let me tell you something about parts.

No one stocks them anymore, but the rental shop guys often sit on a few just incase items.

I need a Honda filter cover not the whole assembly and the best I could manage from a guy that had a stiff to strip wanted 50 bucks for the whole assembly.

I said Nay… 25 maybe ( we have known each other for 25 years or more and play this game often )

Well Ebay has a clone part I am good with so I will order this.

https://www.ebay.com/itm/Metal-Generator-Air-Housing-Filter-For-Honda-GX340-11HP-GX390-13HP-/273823484945

So what is left to do on my TOO DO list is make a plate to shift the rear engine mount forward and remount this to the 1960s Kohler engine cradle…

I need to build an ECM ( from Arduino ) to monitor load and alarms ( like low oil level, under speed, overtemp, low fuel, Liquid fuel > gas change over, and what ever else I can think of ).

I may as well make use of the idle control system and rather than pump 25hz at 60 volts into my home at no load I will run a square wave inverter… a wee fellow, to supply 1000 watts to keep the heat on the circuit in the house until a load is detected, then I can switch to generator after a ramp up and switch the load.

Its like putting a computer in Dad’s 66 Rambler…

Added:

Last night ordered more parts from Aliexpress.

Fuel cut off solenoid and new air filter assembly .

I tried to source this locally a long with idle control board but was told they just can’t help me without part numbers. ( or wont try very hard ).

Cost for a complete new air filter assemble 17 USD shipped to my door in 15 to 30 days ( slow boat ) locally sourced new parts 50 dollars Canadian.

Replacement fuel cut off Solenoid not in stock local. ( I am told everyone here just snips the end off when they fail rather than repair and replace what is essential an anti-diesel part. But I will need this to shut off the flow of gasoline when I switch to gas )

Aliexpress price 7 USD ( Ship China air mail to door free in 7 to 14 days )

The Original distributor ( Koshin America a reputable manufacture of quality pumps and power equipment in Japan ) has been able to find a board but its REALLY expensive at over 200 bucks Canadian.

I thanked him for his efforts and started to look overseas for something compatible but I will likely just end up using an Arduino Nano.

What lessons have I recently been reminded of?

No one has parts, keeps parts in stock and or can just look at a part and say I know what will work.

No one keeps used parts unless they are for personal use like the rental places.

Those guys strip and recycle the parts from a stiff because they understand the cost of simple repairs.

!!! )

!!! )