Hi, Kristijan!

6.4.2017

On mess. 923 you observed that only a “patch” above the restriction entrance is glowing bright despite that all the hearth-area gets equal supply of air, when you have had the lid open for a while.

That is nothing strange! The sides around the glowing center-patch have almost

no draft!

However much air is available above the fuel level, the combustion needs draft through the fuel to glow!

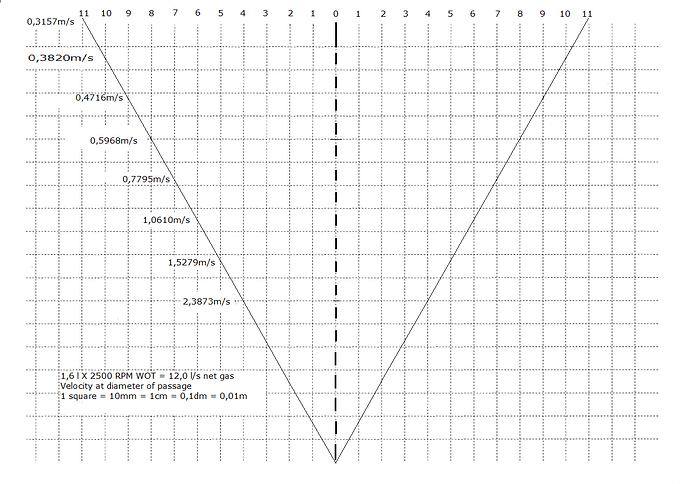

The minimum draft is ~0,5 m/s to keep a fire going!

When the gas demand increases the glow would spread out as long as the increased draft can support a diameter and volume of the “glow-patch” increase.

This will take time, and as you observed, there was not a fast enough response to a fast increase on gas demand…

Now, the uppermost (highest) nozzle row has the task of setting the maximum oxidation volume for top demand.

At “full blow” the oxidation should end at the restriction entrance.

At idle, it happens higher up, and the reduction draft is low above the restriction = cool and weak reduction.

Many’ a constructor has tried out to put smaller-hole nozzles nearer the restriction, but done nothing to control the floppy flow at main nozzles during idle.

To be effective, the main nozzles should be cut out and taken over by an equal in number smole-hole nozzles to sustain a “heart-function” in the upper end.

At the same time the lower end nearer the restriction

should have the same count of small nozzles blasting.

The idea is to retain blast temperatures at the reduction entrance and a live standby top level.

At idle we can use high motor vacuum to get high blastings with the small-nozzles rings, but that asks for cut-off control of the main nozzles,

AND Reinforced filter barrels!

Reason in all! Normally 4 to 6 in of H20 is giving good blasting, so double this would go a long way on idle.

As soon as the normal nozzles are “let loose” all is back to normal for drive. The small ones need no arrangements.