If anyone is interested, this is the news letter for our little organization (ADAPTech). There are two other links within for pics of our projects this week including some of Jakob’s charcoal build.

EDIT: technical difficulties…working on it.

Sorry for the long post. Was trying to just put up a drop box link instead. I will try to do that next time. For now I need to go to bed so I will just post the whole thing.

10/22/17

This week we made some progress on several projects.

Dirtcrete Walkways:

We started pouring test pads of “dirtcrete” . Basically the concept is to replace sand and aggregate in concrete with sifted local Alabama red clay to make a mixture of “concrete” strong enough for walking paths and other applications not requiring the strength of normal concrete.

We have seen dirtcrete walkways that continue to work after 25 years.

We have been unable to find any real good reliable information on a recipe. We did find a reference in a Seabees manual from 1944 which referenced a 14:1 ration of dirt to cement, but it also said that the recipe would change given local conditions, which makes perfect sense. Anywhere you go the consistency of the soil is going to vary. So before continuing with the larger project of the appropriate technology garden, we decided to pour a test sidewalk.

We made one sidewalk with 4 different mixtures indifferent sections. We shall see how it holds up. It looks very good. We used 10:1, 15:1, & 20:1 clay:portland cement. And one section 20:1:4 clay:portland:gravel.

All in all we poured the equivalent of 5/8 of a yard of concrete with less than one bag of portland cement. If it works, that makes an $85.00 sidewalk cost about $8.00 in materials.

At this point it looks like even the 20:1 mix is going to serve its purpose, but we’ll have to wait to see what the rain does to it to know for sure.

Dirt Sifter:

It didn’t take long sifting red clay by hand that the mother-of-invention came knocking. Friday morning the boys and I put together a dirt sifting device. Our initial intent was to make a big complicated contraption, but as usually happens, we looked around to see what we had on hand. Jakob had an old weed eater that someone had thrown out (thanks ethanol gas) and he had rebuilt the carburetor and put new fuel lines etc., and got it running.

We used it to make a vibrator to shake a screen on a slanted table. It was made to vibrate by drilling a hole in the blade and installing a bolt to make the blade imbalanced.

Very seldom does an idea work right the first time with little or no tweaking. This one was one of those.

There are pics in the dropbox.

Bios-sand filter demonstration teaching model

We often find it difficult to capture people’s attention while teaching AT with only words. To address this problem we have started building teaching aids for models that are hard to see. We poured a “1/2 tank” to provide a cross-sectional view of the inside of a filled bio-sand filter, which will be covered with a transparent glass and then filled with the filter media so it can be seen from the outside. It turned out very nice. More to come on this one.

Charcoal Gasifier Tractor

Much progress was made this week on the charcoal powered tractor. Jakob mounted the gasifier hopper, cyclone, hay filter, and built and installed the water-drip tank. For those who have not heard before, the idea here is to make a contraption to allow a combustion engine (in this case a small engine on a small tractor) to run on charcoal made from waste wood and a little bit of hydrogen gas and oxygen gas generated by cracking tap water.

This project is actually Jakob’s enrichment project for school this year. He is well on his way to finishing. We look forward to updates often as he is well motivated.

There are pics in the drop box.

Training

We taught a training session Tuesday afternoon for SIFAT. We had 44+ nursing students from Troy University. We taught Appropriate Technology theory, water purification, brick making and fuel efficient cook stoves. It was a great program.

Hydraulic Ram Pump:

Not much happened this week on this project. Erika and Jesse spent most of the week in Florida at Erika’s uncle’s funeral. He did get the pump operating, but need to fix some leaks and install a delivery pipe. We’ll let you know how it goes…

Project Shop Addition:

Some final touches were put on organizing the project shop after the addition last week. Jakob added on a tool room while I was working out on site last week. It has proved to be extremely helpful in getting projects finished. Everything has a place and most things stay in it… … Jakob gets a great big Thank you from everyone here.

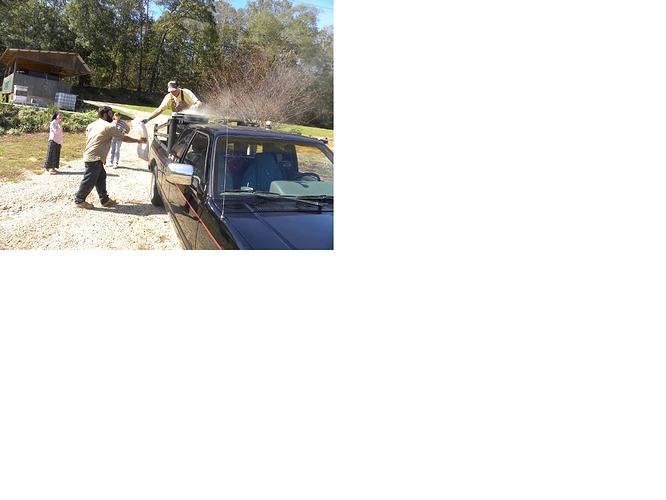

Woodgas visit:

Wayne and Lisa Kieth showed up Friday also. Wayne is pretty well considered the foremost pioneer of wood gasification for automobiles. They pulled in the driveway looking to visit and get a bag of wood as part of a 300 mile trip around Alabama using no gasoline. It was good to visit for a while. And they brought a piece of hose that Jakob needed for his gasifier. Their visit reminded me of my need to fix the leaks in our woodgas truck. So much to do…so few days in the week… …Does anyone know how we can add 2 or 3…LOL

And then there is work and school and all the rest…SO… things are busy here. Hope all is well with all of you out there. See you next time around…Billy

On a personal note. I would ask prayer for the family of Mahalo Gregg. Mahalo was a childhood friend of ours for more than 30 years. He lived with our family for a time when I was a teenager. I got a Rescue Squad call yesterday morning about 1 AM. Mahalo had dove off a boat dock at the lake and hit his head and was not recovered for 15 minuted. They pronounced him DOA at the hospital.

Actually, I just got called out for another rescue mission, so much for taking Erika out to eat tonight. Apparently there is a missing woman on the other end of the county…More later…If you don’t want to get news letters just send me a note back and I’ll take you off the list.

Here are a couple of links to pics for the week: