Guess it wasn’t as damp as you thought… Neat story, one you can tell the grandkids. Solar power is strong stuff!

Hi Ray, I’d better be careful, I use those large stainless bowls, too. I have even heard of fires starting from odd pieces of broken glass laying about on the ground.

I just dumped a load of charcoal and re-loaded the barrel. This barrel will be covered with a wash tub, and tomorrow morning fog and drizzle are in the forecast, so I will set it off just after daylight. The photo shows some large dry chunks that I do not want to cut with my chainsaw because they may contain dirt (from ants and termites). I did see a YouTube of a big hydraulic crusher than would take care of these, but making charcoal out of them will also reduce them to small pieces. This will be barrel number 107. The bottom portion of the barrel is full of foot long chunks of dry wood, and these big hunks are on top. The big piece will probably not be totally carbonized, but it will go into the next barrel to be finished off. Once sorted/sifted/graded/ and bagged, this barrel load will be labelled as “mixed hardwood”. This barrel will about yield three 5 gallon buckets of charcoal plus a bucket of fines, dirt, and grit that will be added to the compost pile. (Sometimes I can get four buckets, but the big chunks will have pieces that go into the next barrel.)

Recently discovered that lining the inside of a charcoal making barrel with old sheets of rusty roofing metal works quite well. It seems to allow the temperature to get higher. I just hung the metal over the edge of the barrel so the bottom of the metal is just above the inlet holes of the barrel. Then I cut a slit in the excess above the barrel so I could hammer it over the lip. Here’s a photo:

Just noticed the text on the photo, and saw the clay sand shovelled over the air holes, so this photo is actually near the end of the charcoal making process, not at the beginning.

This is the 245th barrel of wood converted to charcoal. Here is what I got after 90 minutes:

The variation in color is because I was poking around in the charcoal with a shovel.

Later I will screen this, and run it through the charcoal grinder, and screen it again. Here is a photo of the engine grade charcoal (on the screen), and the fines (underneath) that will go into the compost pile.

Another photo of the fines:

The white stuff is from charred chicken bones. It should add some phosphorus and calcium to the compost.

The posting program warned me that “the last posting to this topic was 1619 days ago, and did I really want to revive it?”.

Well, I didn’t really intend to make charcoal this morning, but when I walked toward my shop I noticed wet grass, no wind, and sort of foggy/overcast pre-dawn conditions. Since the barrel was loaded and covered, I uncovered it, stuck in the torch, and let it rip. No smoke at all!

Thanks for your posts, Ray, I’ve got the bug, but 245 barrels,Wow!

I wanted to see if I could find an easy city-living-friendly way to make charcoal before I dive into converting my 2003 Chevy Cavalier to run on charcoal. I think my current living quarters wouldn’t allow me to make charcoal with fire, but I’m an avid solar chef, so my go-to method is to do it in one of my solar cookers. I just grabbed some sticks from the yard and put them in a mason jar and put that mason jar in my solar cooker.

The first pic is the wood after sitting in the solar cooker for a few hours on day 2.

The the rest of the results shown are after 2.5 days in the solar cooker. Some very smokey tar was created at first and it blacked the lid to the solar cooker.

I don’t know if the wood will get any darker at the temps that I can get with my solar cooker, which is probably 450F max. More than likely them temp just hovers between 350F and 400F most of the time.

Could this semi-charred wood be used in a charcoal gasifier?

A very interesting experiment Aaron , did you allow the volatile’s to vent from the mason jar while cooking ?

If you want to know if its good enough to use for a engine a simple test would be to pile up the contents and set fire to it and watch for yellow flames if it burns with a flame rather than burn with a simmering glow then you will still have too many volatile’s in it to run engines cleanly .

Do you heat your house with wood ? if you have a wood burning fire/ stove then that’s the easiest way to collect engine grade fuel while keeping you nice and warm at the same time .

Dave

What Dave sayd. Wery interasting.

I dubt the charcoal is coocked enough for a updraft gasifier thugh. Those are picky. But this looks like a perfect fuel for a downdraft gasifier!

I saw this riddle in the paper:

Q: What is black when you get it, red

when you use it, and white when you

are all through with it?

A: Charcoal

But I don’t think that is true with gasifiers though. It is more like black when you get it, white when you use it and black when you are all through with it. Maybe it is white/orange when you use it with exhaust added.

Hi Aaron, Nice idea, but you will find engine grade charcoal needs to have the tars cooked out of it and that happens at a red glow. As Dave mentions, light the charcoal on fire and if it has a yellow flame, it has tars.

Gary

This is my favorite way to make charcoal. Sitting around the back yard fire pit with family and friends enjoying the fellowship and laughter. Pour the water on it or shovel it into a air tight container when done. Engine grade charcoal ready to use after a little sifting.

The black fuel to run on your favorite ICE.

Bob

Yes Bob, friends around the fire, a sure blessing. Such

beauty from something so simple. Pepe

I lit up my experimental “charcoal” and it burned with a bright yellow flame. It had less smoke than my other wood though. I think I need to improve my solar cooker if I’m going to get it to work for charcoal. I don’t heat my house with wood, but I recently made a little rocket stove for outdoor activities. I might be able to pack wood into a 10 gallon can and heat it up with the new stove. Anyways, thanks everyone who chimed in.

Hi Aaron , at least you tried it and know what you are up against in terms of heat required to cook the wood through for engine grade charcoal .

A rocket stove would make charcoal great , one thing to help it along would be to wrap the 10 gallon can in insulation material that will speed up the cooking procedure and help cook it all the way through .

Dave

If you keep digging around on this forum you will find that there are basically 2 methods that people use to make charcoal - and heating a closed vessel until you have driven off the volatile fraction is one. I started with that, using 55 gallon drums of wood. It makes very nice charcoal, but it is hard on the container. The other method worth playing around with is a restricted burn - which is to say a simple open fire that somehow prevents air from getting to the coals. If you do it right, it will not smoke at all. The char isnt quite as nice, in my experience, and there will be more ash that will need to be filtered out.

The solar cooker sounds like an interesting experiment, but since the wood has lots of excess energy that you need to cook off anyway, I suspect that you would have a hard time scaling it up.

Keep on tinkering though, and read through some of the charcoal making threads on here - you will find a lot of interesting ideas have been tried already!

Aaron,

A rocket stove is a good idea to fire your 10 gallon retort.

Besides adding insulation as Dave suggested, you can greatly improve the performance by passing a 3 or 4 inch flue pipe vertically through the bottom and lid of the 10 gallon retort can. This internal flue will improve the rocket stove draft and transfer much more heat to the wood in the retort can.

Now here is the trick: Drill several holes into this internal flue/chimney near the bottom of the can/retort. The combination of insulation and an internal flue with pyrolysis gas holes creates a self-sustaining retort that produces high grade charcoal. I have successfully used this modified Anila Stove arrangement on many different retorts from 5 gallons to 55 gallons in size.

As you fill your can with wood to be cooked, use the lid as a guide to make sure the flue pipe stays centered and the lid will mate with the can rim.

During start up, keep the lid loose (or completely off) until the moisture has cooked out of your feedstock wood. You want the moisture to escape freely and not be recirculated through the gas holes in the flue.

When the vapor/smoke changes from white (steam) to yellowish brown (pyrolysis gas), slide your lid down to seal it to the can/retort. Mound up some ashes or dirt on top of the lid to seal around the flue pipe. This will force the flammable pyrolysis gas through the gas holes into the flue pipe and give you a self-sustaining retort that literally roars.

When the supercharged pyrolysis flame dies down, set the can/retort on the ground to seal the bottom and cover the top of the flue pipe. Let it cool, then open up for a dark delight.

Dave,

I forgot to mention that I didn’t vent the jar. I have cooked lots of food in those jars and I’ve found that the jars will expand to release pressure, so I didn’t bother to vent it. It usually means that the lid will be suctioned on very tightly. However, in the case of making the charcoaled wood, the rubber gaskets burnt up completely and I’m sure that they didn’t make a seal anyways.

-Aaron

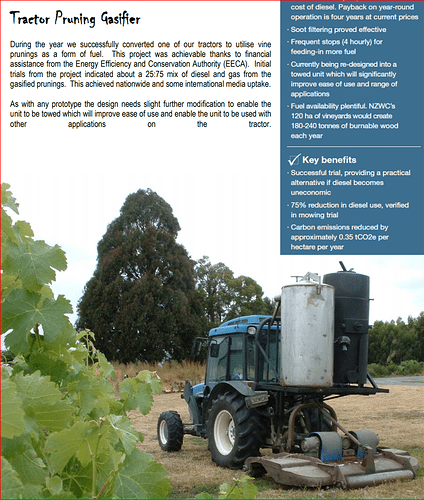

A beautiful idea, transform vine shoot into charcoal, to cultivate with a gasifier tractor the vine surfaces

hello this seems to be great forum. i am from Europe so english is not my first language.

i am very much into the charcoal making these days

i hope this is the right place for my project

i have 300 liter retort with a roket stove that uses the gases to keep the process runing. it works pretty well but i need to upgrade production.

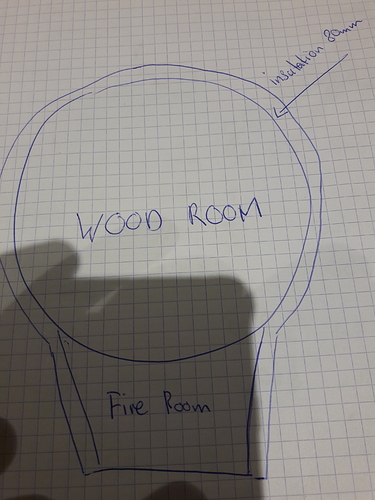

so i got this 3000 liter 1100mm diameter tank her redy to be transferred into a proper sized retort. here is a simple drawing of what i am planing to do

3m long fire room along the bottom of the tank to heat it up. at the end there are 2 long chimneys to give a roket stove efect. i will have a blower or fan to get the fire really hot.

everything is insulated by 80mm rockwool type insulation.

what do you guys think? will it work? will i get enough heat into the wood to start pyrolysis?

thanks for all yor advice.

Hello Steiner and wellcome to the site!

Thats funny actualy, 2 days back l bought a old 2700l tractor pumping sewage cistern, and plan to do exactly what you describe! I am waiting for the owner to deliver it.

I have no dubt it wuld work. I do not think a fan is nessesery. Geting the tank to hot to soon will only warp the walls. What you want is steady medium high heat over a corse of a couple of hours till the wood starts gasing and then monitor the heat from the gas by venting some of it if nessesery, otherwise you can get something l call a supernova. To much heat, makes to much gas, makes even more heat and so on till you get a lot of exelent charcoal real fast, and a kiln that looks like it was near a nuclear bomb

The truth is, 300l kiln is one thing, 3000l kiln is a nother. Concider reinforcing it allso!

Out of curiosity, wich country are you from? I am from Slovenia.