I might have mentioned this before,I dont remember.

When I rebuild my boiler, i plan to make it multi fuel. So in addition to regular cordwood, be ing able to insert a burner for used oil, sawdust, chips, compressed manure briquettes charcoal production, etc. With firewood, it is easy to control the damper to regulate the water temp. The wood will smolder for a long time,then when the damper opens again it will take right off again. Not so with say sawdust or chips! Once you shut down the air supply the fire goes out. My solution is to add extra water for heat storage. The fire can burn wide open until all the water is hot, or until the batch of charcoal is done, and then just shut down and there should be enough heat stored to keep me warm for 24 hours.

Now, the drawback to large volume water storage, is once spent, it takes a long time to get back up to a water temp that will give you any heat in the house. My plan is to use a separate tank(s) which can be shut off. So only the relatively small volume around the firebox has to heat up before you can again draw some off into the house, then add cooler water a little at a time to reheat the larger volume.

Andy, doesn’t the hot water end up in a top layer?

I use a 1,000+ gallon tank, but as soon as a small amount of hot water is produced the radiators have access.

Hmmmm, maybe so? I guess I was just assuming. How do you have your storage tank connected? Does it rely on convection or do you need a pump to circulate it?

Now, this is getting interesting. Without pump you need big diameters and wide turns AND hightdifference. My situation didnot work without pump. Buffer was right next to boiler. But didnot investigate to much and screwed pump in.

Correct me if I am wrong please.

Sorry Matt for of topic

The pump runs as long the exhaust tc thermostat tells it to. A water thermostat mix cold water returning from the tank with hot water to prevent exhaust condensation in the boiler (rust).

If I feed the boiler only a little at the time I can rely on convection to manage a powerout, but not recomended for every day use.

Since boiler and tank are located in the basement I can rely on convection for radiator circulation just fine though.

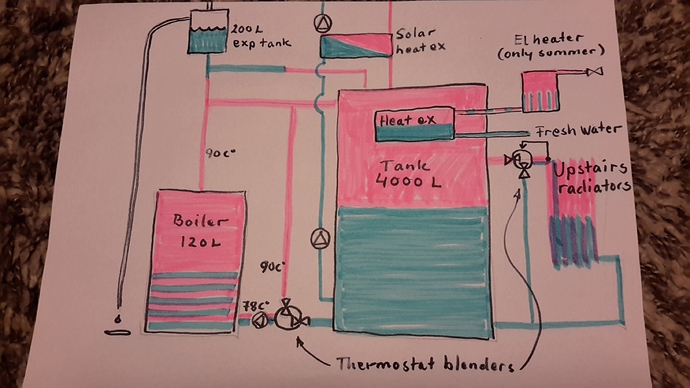

I posted this drawing of my setup a few years back.

@Pelletpower You’re right, you need sturdy piping to transfer 30-50 kW of heat with no pump.

Hi Matt, I like your thinking here. I also think changing from fingers to triangles is better, however, I’m wondering if you only need one revolving shaft instead of two counter rotating ones. This unit reminds me of the high efficiency, clean burning down draft wood burners. Will you have a stack blower to pull the gases through or are you pushing air into the furnace?

Don’t worry about charcoal dust exploding, it cannot. I’ve never gotten it to explode because the nature of charcoal is to glow, not flare.

Try to get a good nights sleep!

Gary in PA

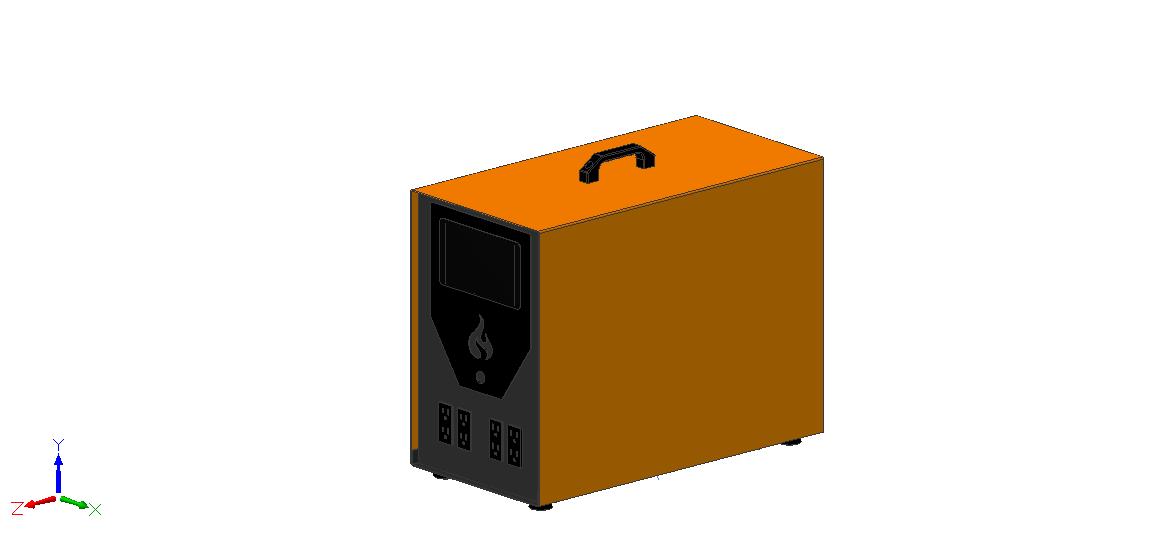

Moving on to the charcoal gasifier unit. I am going to put this and the stove as exclusive products for Versifier, Bio fueled Energy Systems and separated current gasifier systems leaving them with Thrive Off Grid. There will be more products to accompany both the stove and this charcoal unit. I plan to build vertical drive generator built into the same form factor as the Fusion Charcoal Unit. There will probably be two versions and 2500 watt unit and a 5 kW unit. Battery storage systems are next and will be the next project build as I need to update my battery systems. There is a new battery storage product out that is gaining popularity. They are called Solar Generators. They are nothing more than a Lithium Ion battery bank with a built in inverter and they are expensive!!. So my plan is to create a kit for DIY users. It will be the basic housing made of steel to fit a battery bank, an off the shelf inverter and BMS. The DIY user can then build a larger system for a fraction of the cost of these other offerings as second hand cells are now very abundant and cheap. Then there will be the Power Tower!! That will also follow the same form factor as the gasifier. and will be for outdoor storage. This way no worries of the thing light off and burning down your house.

So a complete system would like three units outside that look identical to each other. The gasifier, then engine power unit and then the battery storage with built in inverter. The battery storage systems will be climates controlled specifically in cold weather. There will be a hot water heater coil built in and you can use the house hot water via the wood stove or combination of the engine exhaust heat reclaim.

So anyways the small battery inverter storage system is next as I will never put used lithium ion cells any whee near or inside my house or any building.

Here the run down on the “Not So SimpleFire” lol

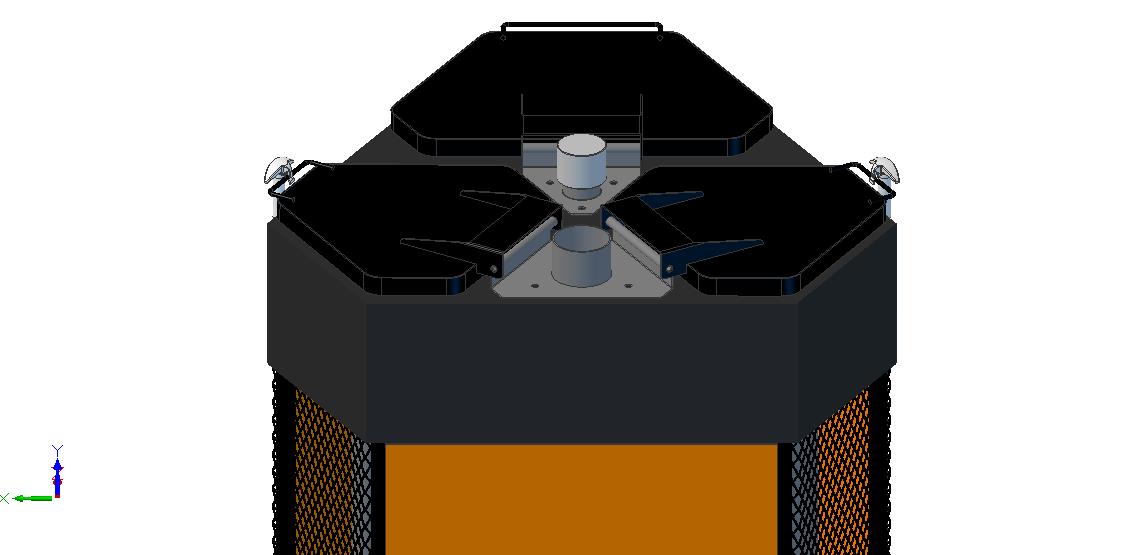

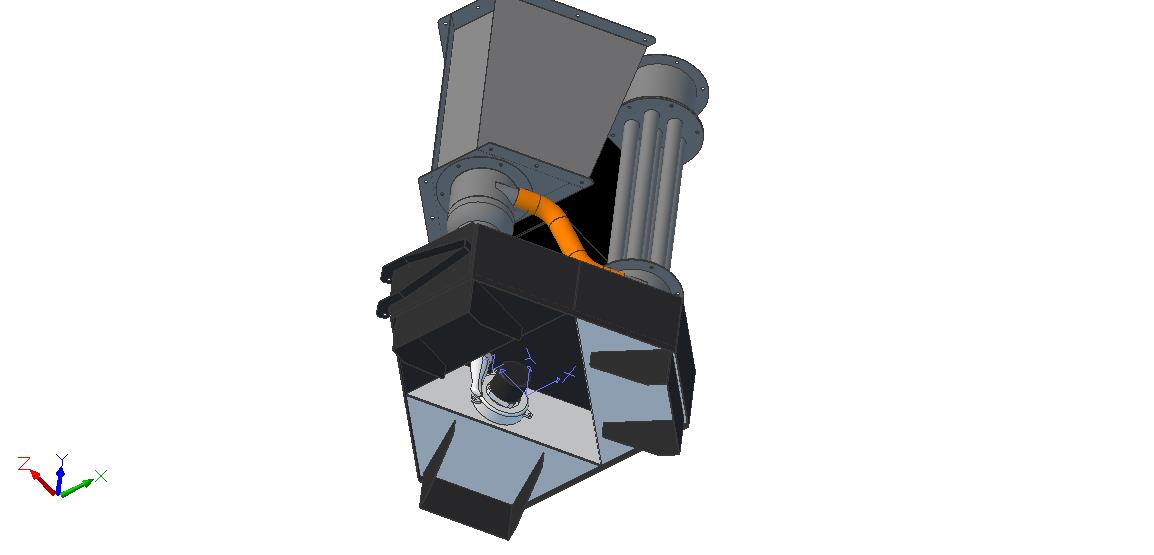

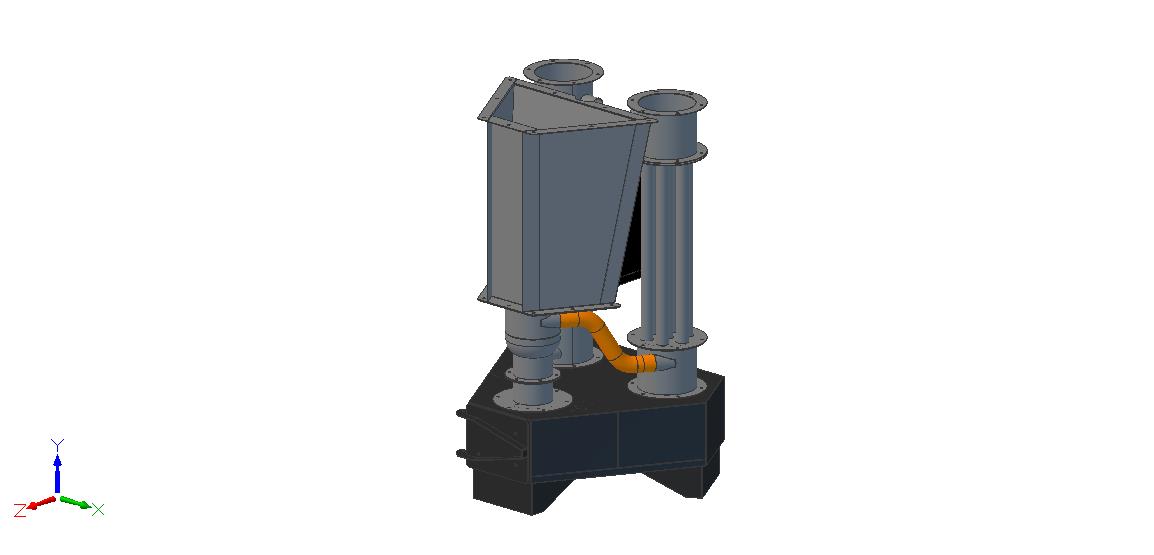

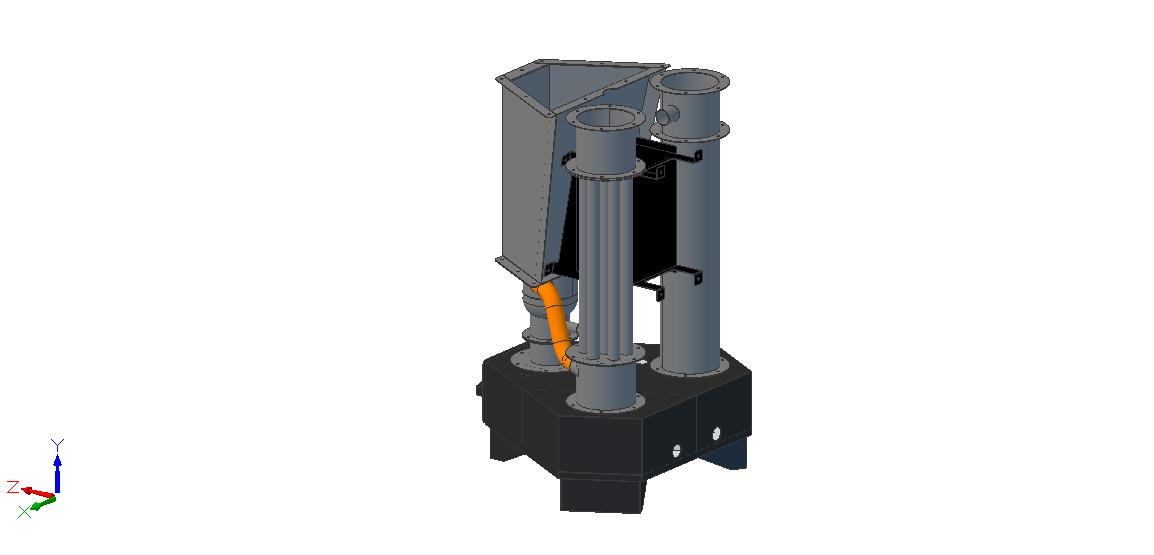

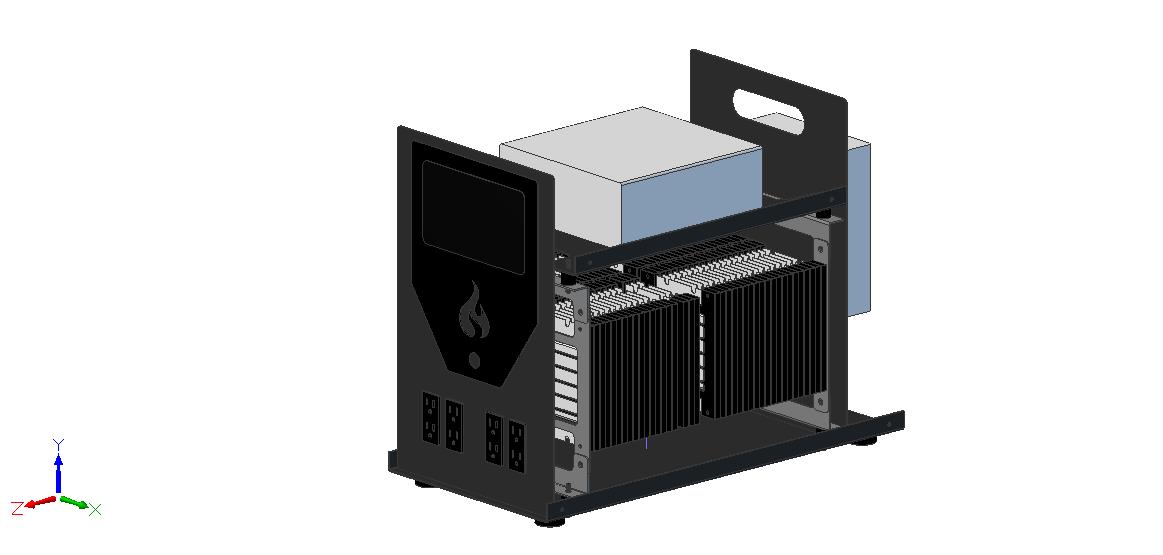

This is here is just the updated ISO as the earlier one was only a shell, this now is a fully modeled complete unit. It exist in cyber space just as it would in the real world

This here is showing some clever integration of the water fill neck and flare cup brackets. They are also the lid hinge mounts. Build it once not twice

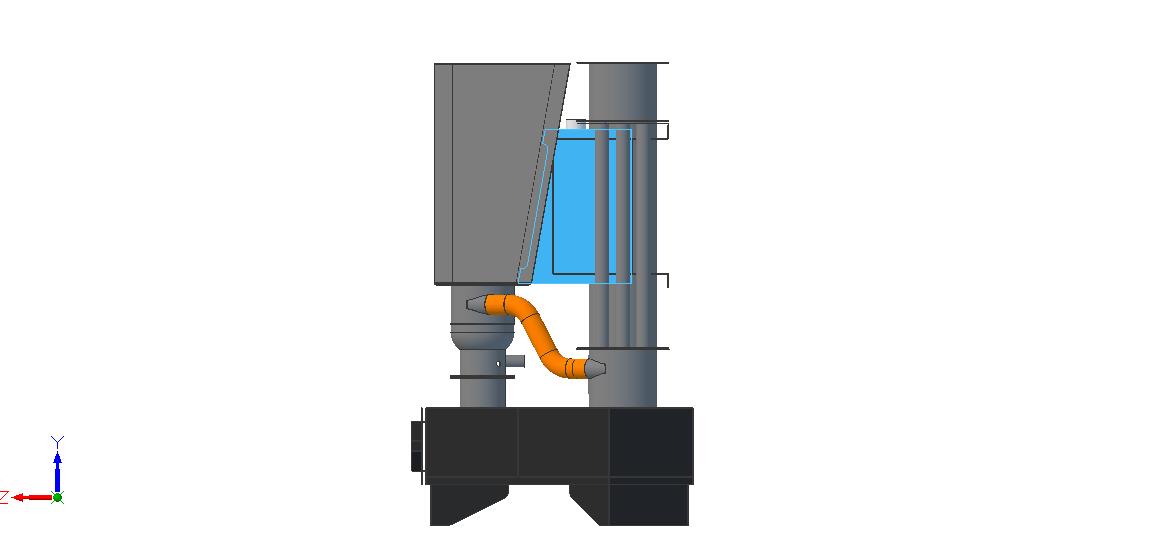

Enclosure is removed the Blue highlighted part is the water tank for the water drip steam reformer. This will have a needle valve with a sight glass to set it. However it will be automated and temperature controlled. In the reactor just above the oxidation zone there is a pan to flash steam from the water drip. it has dam to contain. Inside here is also the air intake manifold to feed air to the jets. This is an updraft unit, however it uses some concepts of prior machines to allow top feed on the fly.

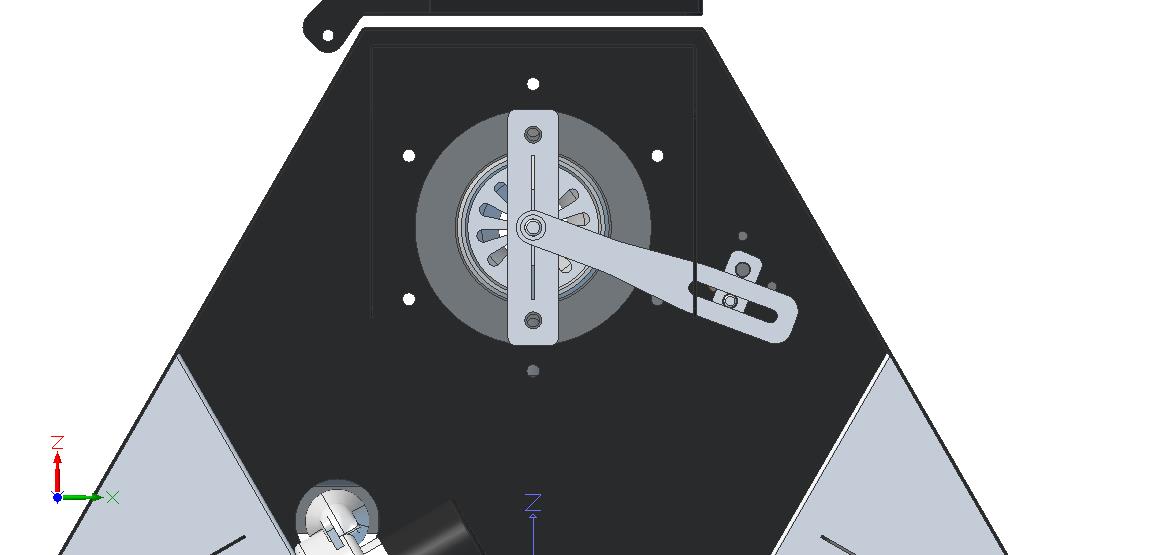

This here is the active grate, this is to ensure the ash is dropping and not just clogging up the grate. This will not work as the same principles as woodgas. Where woodgas is flow oriented process. This will run for a time after a batch run or set to a longer time like every hour. Depends on the dynamics of how the real deal works.

During this design phase I have learned a ton, Charcoal really changes the game when building at this level. I can now put the start up blower at tank level of the final filter. It will be dry here. I direct mounted the grate shaker to the top of the ash bin as air leaks are not an issue. This is where air is introduced from the reactor. So a slight seepage wont hurt a thing. No need for the filter pumps and less filters are required. I think a single silica cloth bag filter will be more than enough. No way dust will get past this filter.

After 8 years of this, this one is mine!! I will have the complete system this year. Stove, gasifier, power unit and outdoor battery storage system!!

I am planning a natural draft chimney, Four inch thru wall then a 6 inch insulated going up. if it dont work than yeah I may need to pull the flows out. Id would not pressurize but use a blower in a venture configuration sort of like an ejector. This way your not exposing the blower to the smoke.

Yup you totally get it, when Im in this creative mode, Im am in a different world and very very focused. If I dont get this stuff out of my head I dont sleep. I finally got this gasifier done and it is the smartest gasifier machine design I have ever come up with. As noted charcoal changes the game a lot here.

“As note charcoal changes the game a lot here.” May I offer an Amen?  Another person sees the light in the darkness of charcoal, a refined fuel. All kidding aside, we need to use both wood and charcoal to gasify. The beauty of charcoal is it’s easy to gasify and clean the gas. You all know about the drawbacks too. Matt, thank you for sharing your thoughts on making this new generation of charcoal producer and power unit. I think you have something going here that can work for the market. I’ll be looking forward to your test runs as the unit comes together.

Another person sees the light in the darkness of charcoal, a refined fuel. All kidding aside, we need to use both wood and charcoal to gasify. The beauty of charcoal is it’s easy to gasify and clean the gas. You all know about the drawbacks too. Matt, thank you for sharing your thoughts on making this new generation of charcoal producer and power unit. I think you have something going here that can work for the market. I’ll be looking forward to your test runs as the unit comes together.

Gary in PA

I have always sayd wood is a analog to crude oil and charcoal is a analog to petrol. You can run a engine on crude oil (early glow bulb engines) and you can run a engine on wood. But charcoal is the way to go if you want a practical small and easy to operate mobile unite.

Gasification is a old old technology but that doesent mean all has been discovered yet…

With todays technology driveing on charcoal might even be possible and practical comercialy. We are mostly all DIYyers and l understand raw wood has advantiges for us regarding less work with fuel and better efficiancy. But imagine for a minute a industryal size plant that can harvest biomass (scrap wood, hemp stalks, poplar or other fast growing biomass) and turn it in to electricity and/or hot water and charcoal. Mill, pelletise (perhaps adding a few % of plastic scrap in as a binder/energy booster?) and sell as motor fuel. If one has acsess to such uniform energy dense feedstock suddenly gasification starts being a lot simpler. Automatisation too…

Just a thod. Sorry Matt, carry on with your interesting thread!

Thanks Kristijan! As a newbee, I am thinking more and more in that direction. Put together a simple fire in just a few hours. Between start build and start flare! Charcoal is right how you see it. Nice job Matt! Charcoal making is the achilles heel.

For hot water I am kicking around an idea of making the grate tubular and flowing water directly through it. Very simple to do!!

Thats how the grate is made on our boiler. Cast iron. Wrong design as it plugged with ash fast and lost all effect but l am sure it culd be made to work

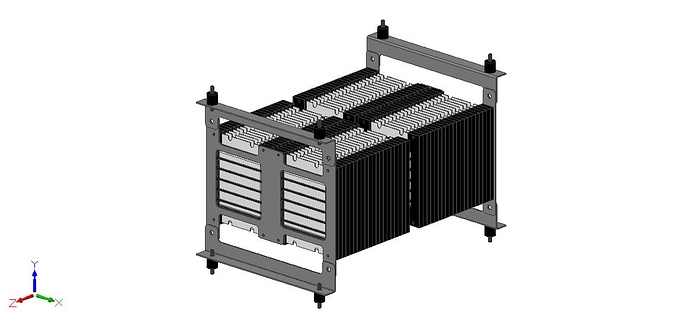

This first kit is designed specifically around a pack battery cell. These are SPIM08HP cells. I dont know the make but you can get them here. https://batteryhookup.com/collections/spim08hp-200a-power/products/spim08hp-3-7v-8ah-200a-lithium-ion-w-cell-holder

So my need for new batteries will spawn a new product line as I will design other kit versions using 18650 cells and will offer a range of sizes eventually building up to the outdoor Fusion Power Tower.

Matt, once again, very interesting! Here we are about to start playing with 18650 but this is far more interesting! No spotwelding! Super! Wich bms are you going to use? I am thinking of a 14s system. Thanks.

And the plan was less projects… My head is in a overflow again… All coming together, that is the good news.

What temperature were the batteries at while charging? I switched over from lead to LFP (lithium iron phosphate) and I am a little paranoid about them getting too cold next winter. I am going to try and keep them above 40F, but 50 might be even better. Other lithium chemistries I believe have similar low temperature issues -where the lithium metal plates the cells and causes a short - but the LFPs are just touchier is what I recall reading. They sure are sweet batteries, though. I hope they give me as many cycles as they are supposed to - I would not have to replace my batteries for decades.

They were inside and hanging on the back wall of the RV. Im not 100% it was the cold, they could have been bad cells or the BMS set up could have also play a part in it. I set it up so the BMS would only cut off the charger and the thought was that the Inverter would cut off at low voltage.

Even though they were inside that back room and this wall can still get cold.

Yeah lead acid just dont work with full cycling. They die off fast,

I am going to re use the 200 amp BMS from my LifePo4 system. It will still work with these cells but the high voltage cut off will be lower than what these cells are capable off. My charger can not achieve this high of voltage anyways. I may upgrade later one.

That is something else we will be working on is our own programmable BMS up to 24 volt systems, to direct interface as part of my controller.

Hey Matt, I have about 200 of these SPIM08HP cells. From what I have researched they need light compression. I am looking for a good way to series, parallel them. I am thinking about all thread with plastic end boards for compression. Parallel 14 cells together, then series 14, for 48v.

Yeah thats what I am planning. Im waiting for them to show up before I order anything. But from the looks of them 1/4-20 will fit the terminal slots. I plan to use all aluminum threaded rod, nuts and washers.

In my CAD model and this is just based on pictures and given dimensions from Battery Hook up. The gap spacing between the terminals is 0.335" So a 7/16 nut with two washers will fit this perfectly. But right now I am only guessing as I dont have the real deal.