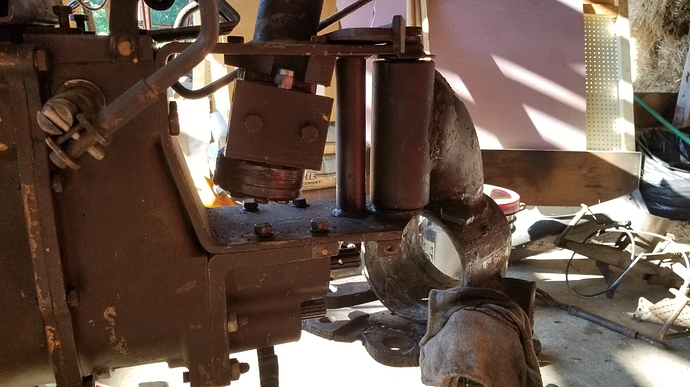

The shim on the pivot is gone just a few bits left now we know why it was loose.

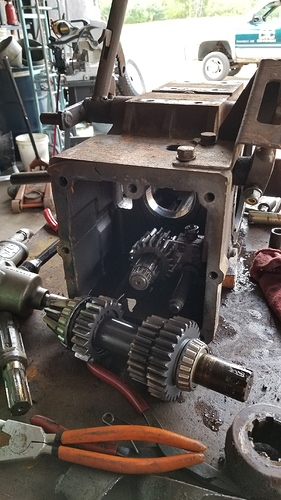

The rear end is totally apart. The rear end was run without oil for a long time before I got the tractor. The bearing for the pto are junk.

Oh and the mystery lever isn’t a locking diff like I was told. It determines if the pto is running at pro speed (540 or 720 selectable at the transmission) neutral or wheel speed. That is how they power to a trailer that has a driven axle. Now I know. Oh the input bearing to the rear end is also junk. I have actually taken this entire tractor apart from the very front to the very back and fixed everything we could find wrong which was alot of stuff.

Well just a couple of quick things on the pasquali the last couple of days. While waiting for John Deere custom parts for my mower we got a few things done one the pasquali and the trencher.

The shim that wasn’t available has been replaced with a fiberglass one custom built to match the ware on the outer casing the inner part was put on a latch and checked it is so close to no ware as to make no difference the outer was clearly softer metal.

There are also new bearing top and bottom of the pivot joint on the smaller tube. We should have everything we need to put the reverend together and back on the tractor now.

The trencher was small mantaince things. Replacing a control cable so it will actually backup now at full speed. Swapping some lines around so the cylinder actually move the way they should when you use the controls small things like that but about a days work on it non the less. I have already used the grader blade and the backhoe on the trencher and really like it. Anyway I digress. I just wanted to show you how we used fiberglass cloth to make a shim for the pivot joint on the pasquali. It will be much tighter now for sure.

Got the rear end back on and together today. Still a bunch of work to do before it is ready for the field but it is getting back together now.

Should put some good paint on that, so it looks as good as all the work you’ve got in it.

It’s going to be a brand new machine by the time you’re done. Should be a pleasure to operate.

Garry paint is in the plan.

That is the color scheme by pasquali that I am going for. They had alot of different colors they used and I honestly don’t know what the original color for this one is because I can’t find that brown anywhere. I am going to use allis Chalmers Persian orange #2 and the AC cream I have some anyway left over from my D15 and it will look good matching the colors of the other 2 tractor.

Excellent colour choices.

Best to think about surface prep and degreasing before stuff gets too hard to access.

Nice job ! I have a 997 with a dozer blade and the Bradco trencher. Parts for the trencher I can get at Ditch Witch. The Pasquali parts well I hunt for them, lol.

Thanks Billy. For the pasquali contact Tom Branch at

https://www.italiantractorparts.com

As far as I know he is the only dealer in North America who sell pasquali parts. He is a great guy and has really helped me out with this project.

My pasquali has a loader which is why I bought it to get into the tight spaces in my barn to clean it out better then I can with the Allis Chalmers D15.

The pasquali is an amazing little machine. I really can’t wait to get it back to a usable state it is close but haying season has really slowed down progress. I have way too many projects.

Quick update got some primer on the pasquali yesterday. Gary wanted to talk to the paint store before starting on the motor as it is aluminum.

That is the loader frame and bulk of all the parts which will be orange. There are a few other parts but it is getting modified to a new seat and some other changes so we need to work out just how the seat and new hydraulics will be mounted. Anyway got a break in the hay weather so I am making a little progress on the tractor restoration.

I also took appart the hydraulics cylinders the first photos are the 4 cylinders that make up the loader. Those are pretty straight forward I just need to get the end fixed where someone stripped out the threads and then bolted it on one cylinder. It fits loose now and breaks the bolt. I think I can put the seals on from the other end and will just get it welded on tight.

The other two cylinders are something I have never seen before. They are single ended cylinders which dont really have a seal just a larger metal end on the rod. No real piston. Someone has welded the ends on them and the o rings leak so I need to get that apart. But to be honest I don’t really understand how those steering cylinders work with one end sealed and the piston not really sealed to the cylinder. Seems like they wouldn’t work at all. I am by no means a hydraulic cylinder expert but those have me scratching my head.

Oh the one orange thing hanging was a test to see how the primer would cover as it is an odd green. Looks ok to me.

Hi DanNH,

I do not know this for sure . . . I’d have to see a hydraulics flow diagram to be sure.

But . . . on some power actuator systems the power-side is given constant pumping power/pressure . . . then the"control" is by letting cylinder out on the opposite side of the leakage by pass flow.

Think of it like air brake systems. The pumped air just retracts the piston rod diaphragm loading a very strong spring. Brakes/actuator is applied by venting out the air pressure out allowing the spring to apply power/force.

Just like most all EFI systems have positive side power constantly applied when energized. The “control” is down circuit of the load (ground side) by letting “out” the electrons flow.

So, your actuator cylinders may need piston bypassing flow to work. IF your actual control valve is on the opposite of the piston as the pump side you’d know this was true.

Regards

tree-farmer Steve unruh

Thanks Steve, what was driving me nuts is those rods are actually loose inside the cylinder. But they cylinders are closed volumes with no air vent so it works by simple volume displacement the pump forces fluid into the cylinder which displaces the rod and forces it to extend. The single acting cylinders I have seen before still had a seal on the oil side and an air vent on the other side. These two cylinders are one on either side of the pivot so the cylinder on one side is forcing the fluid out of the other cylinder on the other side as it turns. I guess the good news is the o ring seals are the only failure point on these cylinders but it is a new design on me.

Ahh. I see now.

The non powered side cylinder having it’s cylinder-full of fluid forced out would add a dampening effect onto the system too.

S.U.

Not much to report on the pasquali project it has mostly been just waiting as I work on other more important farm projects. But we did get most of the painting done so i decided to upload some photos of the progress. It is getting closer to finished at any rate.

Not much new. Went to put the tires on the other day and one of the rims I has fixed had a sharp edge which punctured the new tube so I had to take that back to the shop. Got the tires and brakes on today. Still waiting to get the cylinder back from the friend who is doing some welding repairs for me. I find the trading favors system can be slow but the price is right.

The fenders and seat are just sitting there for a mock up. I might have to modify the rear fender mounts for the new seat bracket but I have a front to back adjustable spring loaded seat mount I can use it will be really nice to have a little bounce in that seat it was a rough ride before.

There is a quick mock up of the front grill as well. It might need another coat of paint on the cream I am not sure. I will make a filler plate to mount the round lights and I think 2 more maybe on the front fenders as the buck blocks the grill lights half the time.

I am also planning red marker lights on the back fenders and a work light on the back as well.

Sometimes you just need to walk away from a problem and come back the next day. Yesterday I was looking at that seat with the cushions on it and couldn’t see how to make the old Allis Chalmers hinge work with the Kubota seat frame I have. The AC seat mount is way too big for this tractor. Today I walked back there to do something else and in one glance I went well remove the cushions and take the angle grinder and cut those 4 welds then you have a flat seat pan to work with. Now I just need to decide if the seat pan is thick enough to support the springs because that plate I cut off was giving it alot of support. I might take an old piece of steal around here to stiffen it up a little before mounting the new bracket to the seat.

That’s going to be such a sweet little tractor. To me it looks like it’s begging to go in the bush to skid logs…

That is how if got broken by the last owner. They where a favorite for loggers on small lots where they didn’t want to cut roads but the center pivot is a little light for the job. You can see where this one was broken in two by the logging winch they used on it. But they did a good job repairing it. I saw that when I bought it.

Ok, scratch that idea, or go easy on it - maybe using a log arch / fetching arch?

I suspect it is like most things and you just need to know the limits of the machine. The logging winch which was on it looked about twice as big as I would think was reasonable for a machine this size. It was category 1 3 point hitch but it looked really big and heavy on this tractor.

One of my dreams for this tractors is a dump trailer and wood splitter powered off rear remotes so I can take the splitter out and split wood directly into the trailer in remote places where you don’t have to worry about hauling out big stuff. Or to load logs on a trailer and bring them back to the mill. I so like a logging arch the only down side is they are one more specialty tool if I can get by with a flat bed trailer I can do more with the same tool.

Depends how tight it is in the bush, and how rough. If you have a nearby field / landing area it is likely more efficient to skid out to an open work area.

A fetching arch is a pretty easy build, you need to hone up on welding and fab…

Community colleges often have evening short courses, well worth the time put in