I think I will continue with my foam rubber mattress as an extra filter, it seems to work well, and it will be close to the barrel as well, I do cleaning as Don said, out on the lawn and on with the boots and rinse with water.

Here the horse owners want cutter shavings, I fill in pits and irregularities on the forest roads, had a little on the fields as well, but think it takes a lot of nitrogen when decomposing.

A little bit of everything mentioned, but mostly I just put my mill in a slightly different location next time.

My mill produces almost similar to cutter shavings, but only 4mm wide. If fairly dry I sometimes bag up and add to the attic insulation.

Well, I have been researching and gathering materials. I have decided Aly and I will start working on our first mill around the second week of January. So far, it seems a bandsaw mill will be our best immediate return on investment. We have made a few offers on some land and one is very hopeful. Our goal is to have the mill built before we close on a new property. Once our last house is sold we intend to buy a backhoe and start logging the land, sawing boards and Kant’s and building a few solar kiln’s. We hope to have already broken ground towards building our own home by August this coming year! What does everyone else have going on? Happy holidays! -John

Bandsaw mill is the best way to go John. If you sketch up some plans for how you will build I can possibly suggest some things to you I learned from my own trial and error. Right now I am reworking the base on mine in a new, fixed location. I will start off by saying that a set up like Waynes where the log rides into the blade is in my mind better that running the carriage, motor and blade into the log. Which is unfortunately what I’m going back to since I don’t have money to extend my track right now. Good luck. Making your own power, cutting your own wood, growing your own food. These are all personally empowering in ways that the average person cannot start to comprehend.

Kristianjan asked someone about this blade guides for their mill. I don’t remember which thread that was in. This is how I made mine. Probably wouldn’t go this elaborate again but when I did it all I had to draw from was the guides on my band saw.

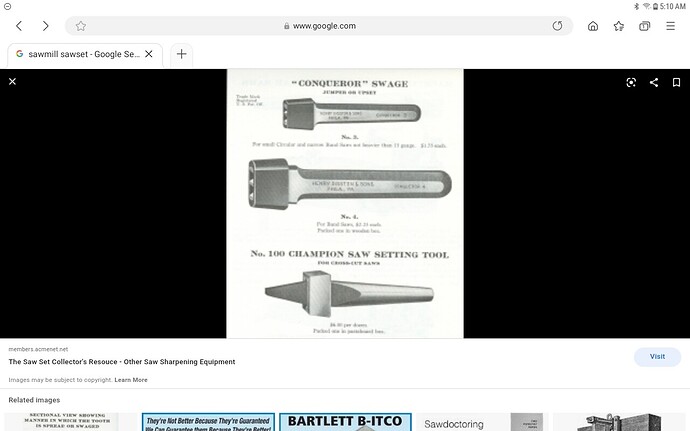

When I was a teenager, an older friend showed me and told me about one of these tools. Similar to the top two in the picture. I have never seen another since then.

Curious if any of you are familiar?

Completely different from what I’m know about swages. I have what’s called a swage tool to tighten the bands on PEX fittings and have used a different one to close a ferrule on wire rope.

Hey AndyH,

The shape of these says they were hand held and mallet tapped down by their rounded butt ends. Teeth angle setters.

S.U.

I have one down in the shop. They are made to swage circle saw teeth on a inserted tooth saw mill. The big end of the tool has two V-s in it one spreads the tooth and the other narrows it. Just set it on top of the tooth and hit with a hammer. The teeth on a circle are all strait so this puts the set in for clearance on the blade

Jim goes gets the prize! Thats exactly how it was explained to me.

Interesting Andy!

I have hand held plier like set, for none insert teeth. Works for the smaller blades.

TomH, I have a swagging hammer for cable. I use it to install cable terminal ends.

Of course my first thought when I saw Andy’s sets was calking chisels for sealing leaky boilers.

Used one or two for about 10 years. It’s all about the corners. That is where it all happens. My saw blade was junk. Saw lead, swedging, sharpening and oiling Babbitt bearings . . . When pouring a Babbitt bearing, make sure to use Babbitt rite. Otherwise, mining for Babbitt we go !

A few years back I was resetting my band blades but found I come out a little better just to sharpen them down until a set was needed and scaping them . It seem to me that the very tips of the teeth may have been harden and when it was gone the blade didn’t cut true

Wayne,

After thinking about it actually my experience is very similar to yours. I think they’re making saws better than they used to. The lower saw is about 12 years old. So, relatively new. You can kind of see that the teeth have been tempered. It’s a really good saw. I have never sharpened it, but it cuts like brand new. The other one is from the late 1970s. The first tool I ever spent money on. Its okay. But I’ve have sharpened it a few times. Now it needs to be set. I think I’ll try this guy’s method with a screw.

Rindert

Those are also

commonly called a nicopress.

Anyone here ever get the pleasure to run a mobile dimensions mill? Highest production small mill I have ever seen built in oregon for the pacific northwest, lightweight super mobile breaks down fast and can be set for any size log. Single double tripple or quadruple cuts on a single pass depending on setup. Can saw 3 boards per cut and autofeeds the cut board back to the operator. Friend of mine worked at a small mill in the tiny town of burnett that had 2 of them one mobile one stationary along with a woodmizer lt15 bandsaw mill. Loved watching these machines working! The mill is still there but the owner has retired and sold off one of them. Company is still around and I’m told will still make mills for people on a order basis. Someday I’ll have one

Little video for you guys to see

My father had a 16’ mobile dimension saw.

He used it to build a home in Wrangell, AK. Then brought it to Foster, OR to build several barns and additions to their home on his 100 acre farm.

I helped to cut up several 36” Douglas fir logs to build a deck and wood pile shed at my home in Washington.

Logging, Lumber making is FUN!

That was interesting. Only mill I’ve seen that gives you S4S in one pass. Wouldn’t be building a framed house with it in Michigan though unless you found a way to get the lumber grade stamped. Snow here is almost gone. I’ll be getting my mill set back up real soon. I’m going to have to check and see where they are getting those VW engines. They are far and few inbetween around here now.

Looked it up. I guess they are available from several sources. About 2K per.

Second part of the Mobile Dimension 1982 Demo video series:

Back in 2006 when I was selecting for my own saw mill I got a Demo DVD from an Oregon company. Can’t recall it’s name. System did have circular blades with edger’s blades. But that DVD DID NOT have any portability (take-to-log) claim in it.

Why I went with the portable, Peterson swing blade system.

I did not have the log moving equipment to move the cut logs to the mill.

Did not want to turn my wood lot into a muddy rutted mess.

I wished I would have seen this video series back then.

I would have certainly chosen differently.

Peterson and others only stay on their tracks by gravity weight. Hit a knot hard spot; a twist grain section; debris blown up onto the track ridge, and I’ve seen power unit lifting.

Kinnda’ scary.

This Dimensions system is track restrained; cut travel, gear driving from the underside of the track edge.

Safety first.

S.U.