Welcome to DOW. You certainly do seem to have all needed skills to finish the project, and have about 2/3 of the fab work accomplished.

You’ve certainly come to the right place for final design and assembly info to make a working system.

You state in the video you have a Volvo with an automatic transmission, but think you need a manual for best results. If you look at the examples of builds here, most are automatics. And the best performing conversions are low rpm, bigger displacement, over powered engines for their application, though Mr Olsson in Sweden may want to comment, as he’s run 2 quite successful systems of smaller displacement, higher rpm.

A gas (petrol) powered tractor shouldn’t be discounted as a candidate.

You mention discussion with a fellow in Sweden - what design parameters are you working from? I assume Imbert dimensions, and calculated on what flow / displacement engine, at what rpm? What are you considering for hopper design? Members here like cross sectional sketches, and pics.

Hopefully you have an engine based design calculation, and @gasman can help check fundamentals. Although, the essential calculations are clearly laid out on the woodgas.nl site under DIY.

Btw, cones can be fabricated easily from flat sheet steel. A pattern can be derived by making 2 half circles representing the large and small diameter in light plywood, joined by a piece representing the height. When rolled on a flat surface they will describe 1/2 the pattern.

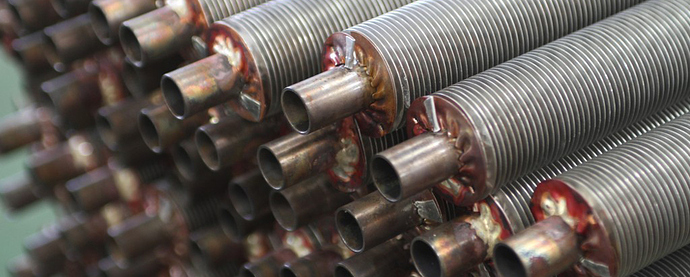

The grate you show might be improved on. Experienced members can guide you regarding spacing and shaking. The shaking is usually a rotating or sliding action, and often proves unimportant on a vehicle mounted system. Spacing is important to slip the right size of char. The optimal heat resistant grate design is inverted light angles to allow ash protection from above, and heat radiation to below, and solidly attached alternately on one side only to avoid warping, though many grates here are just stainless plate torched through, hung on chains for movement.