Dear Steve,

you are correct about the generator gas numbers, coming from “old style” coal gasifiers.

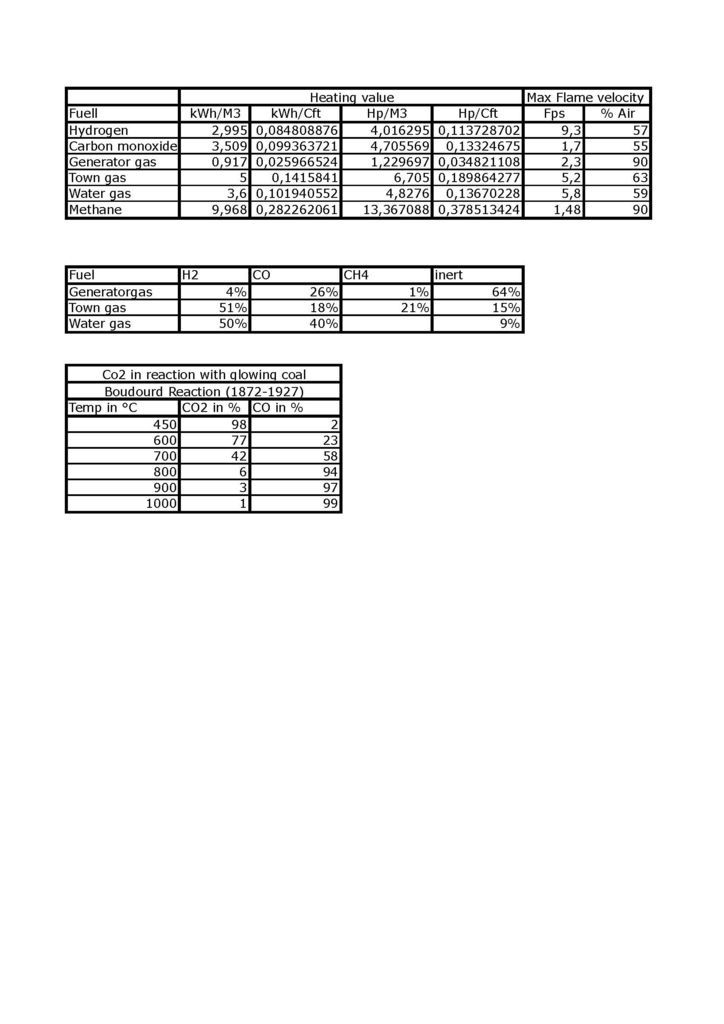

in this topic i want to point out to the importance to understand some of these numbers to make decisions in adjustments.

know what to do, how to do, why to do and then do it…

the awareness is similar with adjusting an “ancient” carburetor :-), you need to know why you turn the screw …

The numbers are for indication purpose and comparing only.

the horsepower numbers are relevant to the calculation for the efficiency. you can break them down towards energy/weight

as you stated very correct, real numbers are depending the real situations…

but only if you know the meaning from the numbers you can decide if your mixture need adjustment and what kind of adjustment it need…

basically is that the tittle of this topic…

However, it is important to compare the processes off gasification to determ what kind of gas you want to have, rich on Hydrogen, increases the flame velocity and the reaction , dough little less power.

as you might know there are a few tweaks possible how to obtain that increase.

same as for obtaining more Carbon monoxide or the methane.

but that is not this topic, i will bring some idea’s to debate about in next topics, hope to have the change to learn from you guy’s experiences.

i did learn already here , believe me

for my project in Thailand therefore, i decided to proceed in next step to build a “gilmore style” charcoal gasifier to be the “farmer gasifier”

Charcoal will always be the fuel.

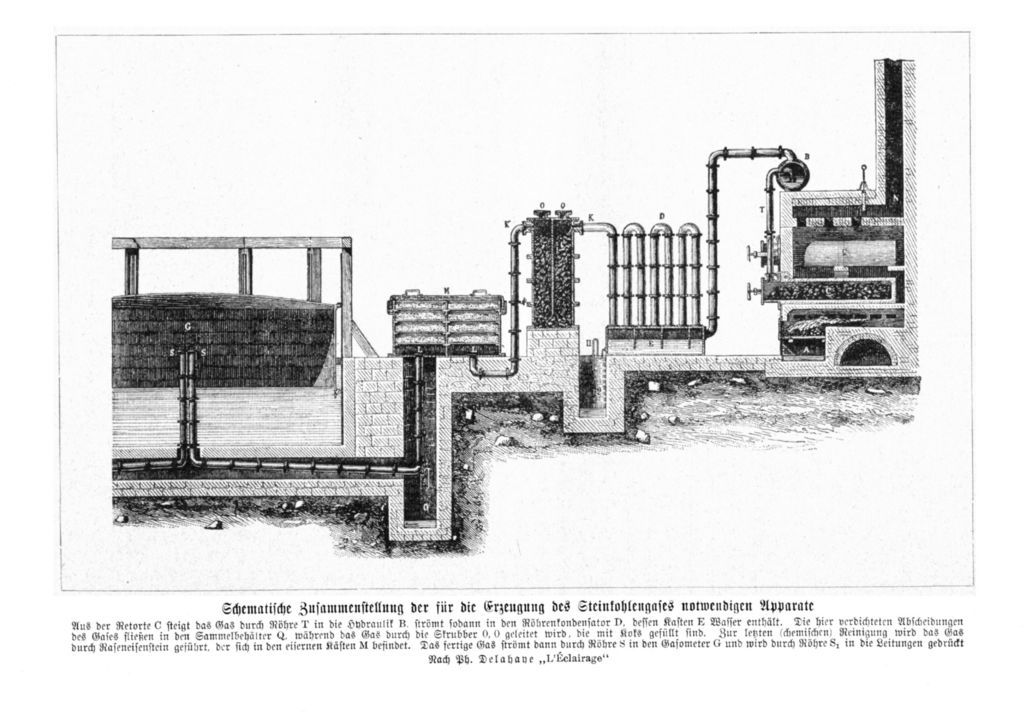

for the community gasifier i am thinking on a crossdraft system with ancient filtering ( same as the old gas factory’s had)

advice and idea’s always welcome.

Further, i am well aware that i know so little, but i will open my mouth if i see that my knowledge can contribute in finding the missing piece.

Should i keep quit when i know i have the missing puzzle piece ?

As far as my knowledge goes, if my small contribution helps to set new world records for Wayne, please feel free to use my knowledge, i don’t need credits for what i learned from others.

as goes for some great people i did meet in life, without any previous knowledge they where re -inventing the wheel… i deeply respect them because they did it with their intelligence by themselves and not by the book.

my job life made me think mostly in black and white, seeking and finding the errors…

finding the errors in myself is the biggest challenge, thinking grey only

for the projects in Thailand, all private initiatives… doing it and hoping it will be copied.

Willing to learn at any time.

Kind regards

Koen