Here a video wher you can actualy see the effect of hydrogen

Listen the rev’s

Good subject Koen…

I didn’t have time to read the whole thread (but i will later) and I am just a learner myself. One thing to point out about the environmental impact is that one of Wayne’s vehicles stated his smog numbers would pass a California smog which are known to be the most stringent in the United States.

Also the benefit of the gasifier is wood is renewable, so it does’t have to be “better than” oil so to speak - which as we know are at the bottom of the barrel in reserves. This comes down to cost and availability, which at this time the gasifier is very much more cost effective, and fuel supply much more available than oil (since it is running out). I know your looking for better research numbers but I thought I would just point this out.

Good morning Neal,

To support your point of view…

Any SSS study will reveal that oil is only used for convenience and for tax reasons… and of course for the financial benefits of a few…

Any SSS study will also reveal that using gasification wil solve unemployment and a lot of the ecological problems, including waste managment.

To the topic… gathering all knowledge about the power inside woodgas and create good understanding about the ability to control the contents, thats my purpose in this topic.

There are a lot off possibility’s for further improvement in the use of woodgas and a great deal of the solutions are to find in the “old” knowledge…

and the knowledge is what i am looking for…

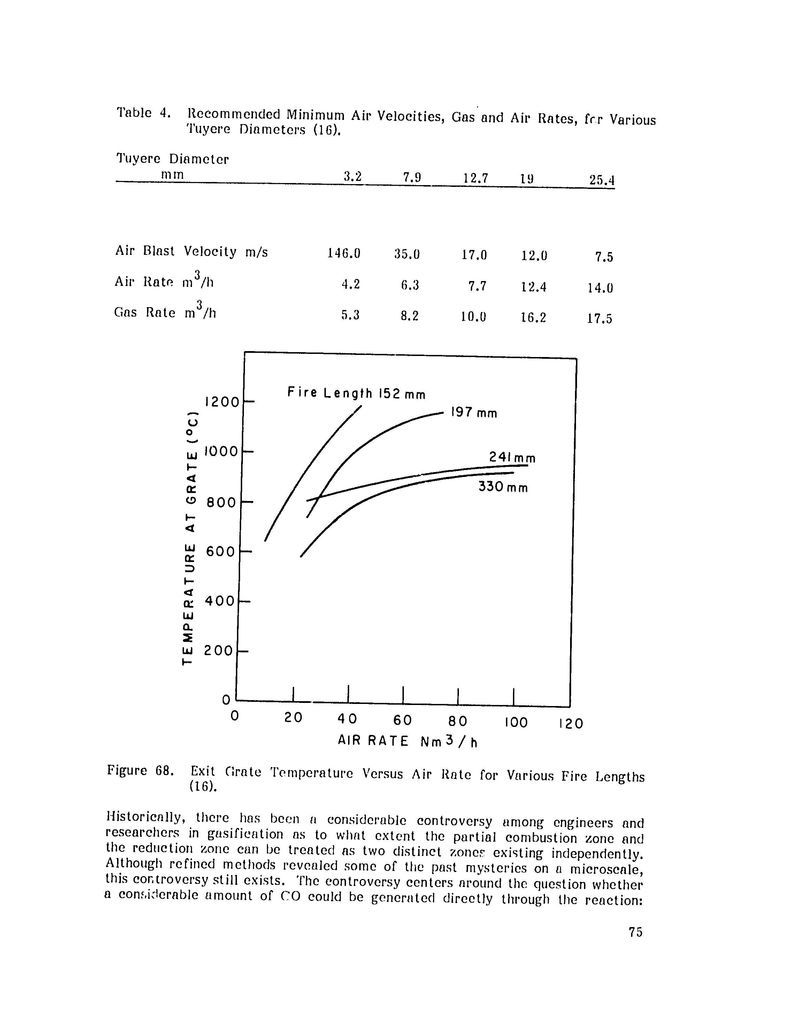

An overview of the effect on airspeed at the nozzles towards the conversion from carbon into CO

and a link for the document

https://docs.google.com/file/d/0B4CL3bqit0osY2Q4aldjYWgteEk/edit?usp=sharing

Hi Koen,

Is the seal in that pump in the video going to be okay? I thought they did not like running dry.

Gary

Hi Gary H,

Not sure, its a brand new one, but they are really self priming so should be able to withstand some time running dry

I am preparing a longer test under load with it. so i have to wait and see…

To self prime it still needs water in the pump, no doubt a new seal will not be more than a few hundred Baht.

Have you tried lighting the gas coming out of your blower?

Basicaly the advantage from the hydrogen in the mixture;

- no need for changing the timing - ignition

- Higher RPM possible

- Less derating of power compared to only CO ( compared with power of gasoline)

Hi Koen,

I blew up your photo, the cooler part, so people could see the simplicity of the linear flow design compared to the one I built. Hot gas meets cooler water and more water condenses out. The s-trap keeps the water level constant as any water in the base higher than the top of the “S” will automatically drain out. The metal chamber separations force the hot gas to take the path of least resistance which is through the pipes forcing the linear flow insuring maximum contact with the radiating surfaces. My linear flow cools very well, but my design is much more complex to build and a bit more involved to drain. The setup for the S-trap requires some thought as far as accommodating the height is concerned, but not difficult. Also need to be able to bring water level up if necessary.

And of course, freezing weather presents its own restrictions/ challenges on operating with this design. Never a dull moment.

Pepe

Hi Pepe,

I am a bit slow on the internet these days  ( low connection speeds… )

( low connection speeds… )

Nicely done the pictures, the water also can be used with a sprayer in the top part of the tubing and be used as scrubber,

The gas content is also important to know for the effect on the filtermedia, the faster its cooled down, the better.

I am also researching about the colors for the cooler and it seems that Black painted on the outside cools the best/fastest.

So thin walls from stainless with a black coating would be the perfect choice for me to make.

( black absorbs the most but also emits the most , shiny stainless is factor 1/100th of matt black, white is factor 1/10th, both in absorbing as in emitting. )

( for my house i want mirror walls at daytime and matt black at night  )

)

Your design, as build already, can you adapt it to the old design as in the pictures or would that be to difficult ?

Greetings from the cold saison in Thailand… its a “freezing” 20°C at night time

Here a link to the website from air-liquide for the contents of different gasses, interesting i would say

http://www.encyclopedia.airliquide.com/Encyclopedia.asp?GasID=41#GeneralData

and a picture of one of my studies about gas-volume by temperature

for those who are interested, i will upload the original, spreadsheet, so you could play around with it.

For making visual the volume difference with the temperatures

I have used black exhaust paint on my gasifier, it is able to handle high temperatures.

Painting the inside of the cooler would most likely help also especially if it is stainless steel.

We where planning to build a house in Thailand, I was going to run water pipes through the concrete from the canal that is close by for cooling. It would only require a small pump using much less power than a AC.

Hi Gary H.

Can the inside painting resist the corrosive gasses ?

I am building my house here to, but not a Thai style…

I am building solid thick walls sun side ( 40 cm thick) to keep the heat going to the bottom, outside using calcium oxide

These walls will cool down the building and absorb the humidity from inside.

But gasification the topic

I am using the gasifier for reloading the batteries for the night, pumping the water to the cisternes, heating the water for the showers, and… for airco… ( old airco set from a car ) to cool the bedroom if needed.

My house foundation is a huge solid rock ( sand stone ) and i use every old trick , with some new technology…

In what area you are living in Thailand ?

https://drive.google.com/file/d/0B4CL3bqit0osTjE3b09zckRFR1k/edit?usp=sharing

This spreadsheet is based on my research.

For those who like to play with numbers and gather some insight.

Alter the yellow fields and see the results.

Only for information purposes…

It also considers the amount of oxygen in the producergas and it calculates in the case of 100% stoichiometric value, total combustion.

Enjoy

Koen

edit:

I had to edit the spreadsheet, coz i discovered my failure. converting Kwh/m3 to Hp/m3

now it should be correct.

For those who are already using it, but did not see;… change the formula into / instead of *