I want to be able to offer them at some point. Id really like a Tesla Power Wall. No $$

I hear ya I was hesitant its a chunk of change I was well my batteries were on there way out and had to decide either go with what I have done for 16 years or charge it and its nice not being a slave to the system you at least don’t have a lot invested it your current batteries cant beat 25 bucks a pop. those powerwalls do look nice and would make for a nice addition  congrats on cutting the cord by the way.

congrats on cutting the cord by the way.

Hi Paul, how many, and what kind of batts.? I am ready to go off grid, researching all options. Going with solar, and hydro. What all do you run?(daily usage) Do you use gen. for high demand(welder, air compressor)? sorry for all the questions, but no one around here to get a real life scenario . Thanks

I cant really input a whole lot here, actually kinda new to this myself, just have done a lot of research up to now. But if you look into your typical car batteries, from what I have uncovered they are good to around 45ah. However this is rating them with something like 8 volts as the threshold that they are considered dead. This is only a rule of thumb they are all different but this can be used as a guideline. Now with my inverter it cuts out when the batteries get down to 10 volts or 40 volts pr bank. So that drastically cuts that number down. But I figured, when just pulling to supply the RV Im pulling roughly 15 amps for 1.5 hours this is with lights on, TV, PC etc. So If Im doing this math correctly Im getting around 22.5 hours for the two banks. So then I believe to calculate this pr bank I then divide by the number of banks I have (2) so that gives me 11.25ah pr bank. My goal would be have enough power for 8 hours. So I think I would need at least 6 of these 48 volts banks to achieve that. However I need to do some actual work like running the CNC machine for a few hours a day I think I will need more.

Need to start thread on reconditioning batteries any one here with some experience doing this?

So I dialed the grate shaker way back, I made 20 to 40 second increments through out the day and gave it time to self adjust. It started out at 40 seconds between grate intervention and it is now throttled back to 220 seconds. Intake air valve angle has slightly changed getting it closer to 50% open, this is closer to where it should be, but is still more on the open side. I see less smoke pulsing out now and this last check It poured out a shot of black condensate and not a drop of that thick tar it was producing.

So I shut down without a gasoline wash this run and am now going to sit back and time the batt capacity. If I can keep shutting down like this then I can cut my fuel consumption down a bit instead of running this thing full time during my hours Im awake.

Last night I was testing the hopper capacity and let it go for two hours. It just sat there and put, put, put, put all the way until fuel was past the hearth bowl. Ooops!! So that may have been a good thing as it probably turned the build up at the walls in the reduction to white ash. But getting it re established wasnt much fun sprayed tar all over the place. This is why I generally shoot our flare cup out horizontally.

good question al I have 6 100 amp hr lifepo4 now and and use dish lights 50 in tv vcr computer toaster brake lathe drills grinders drill press water pump . no generator .

my lifts are gas driven along with welder and fridge only because of old leadacid system I had to run the generator every day for 6 months of the year for 4-6 hours a day in the summer it was a lot less but if I had 4 rotors to turn had to start the generator if I ran fans all day and night generator vacuum generator you get the drift . now on a cloudy day 5 showers in a row no problem rotors no problem fans no problem . I compare it to the new cordless tools any body that had an old drill that took 8 hrs to charge to maybe get 2 hrs run now takes 45 min to charge and goes for hours . they do cost more but last a lot longer and more user friendly. .

after all your figuring divide in half again lead acid don’t like to be below 50% it shortens there life a lot .

does my calculation sound right? Is that all you really get from them. haha!!

it looks right and as they get old it only gets worse. but on the good side you don’t have a lot invested yet it can be done on the cheap or cheaper than I did people are building the own powerwalls with 18650 for pennies on the dollar or look up replacement battery packs for hybrid vehicles the prices have come down a lot you just half to be a little savey with setting up battery monitor systems. what was I thinking I follow your post you got this.

Yup I really would like to try and build one. Time is the only thing I dont got. Maybe this winter, Im slowing down on development, the machines are pretty good where they are. Next advancements will be more controls electronic oriented. There will be things in place to detect when things are not right and force shut down to prevent tar issues. Ease of use, web monitoring etc. Besides this the battery tech is the next step in making these systems practical for the average Joe. Just push a button and go watch TV

Matt, I am not an expert on much of anything, but here is what I know. Yes, Lithium batteries are great and as the price comes down, that may be the best option. In 1980’s and 1990’s electric car conversions, the most bang for the buck came by making battery banks out of multiple 6 volt flooded lead-acid golf cart batteries. They are a deep-cycle battery and can handle being discharged to a lower voltage than a used car starting battery. Rural King price on those is about $70 each plus tax and core charge. There may be a source of used ones (golf course?). I haven’t found one yet, and would have to buy new ones. You could make up one 48V bank of these and compare, a good size investment I’m afraid. (Any good batteries are!)

Hi Matt , Mike is spot on with the golf cart batteries ,Trojan T105’s are the most common , and the much larger L16’s are the ones to go after if you can , unless old car batteries are all you can get then make do with whatever you can get hold of but they wont last long .

I have got hold of a lot of deep cycle batteries the 6 volt T105’s and L16’s and used a product called EDTA with them to help desulphate the cells and have managed another 4 or 5 years worth of use out of scrap batteries so worth the shipping cost from the States to here in Australia for me , have a read up on the edta salts and see if its worth the $15 a pound to play with on your dying cells , i bought mine from a company called Trailhead supply , no idea where in the states they are but do have there phone number is wanted .

Cheers Dave

Just a thought i am looking at maybe bidding on one of these units that are local to me , maybe you have something like this close to where you are Matt .

http://www.graysonline.com/lot/0091-3013894/computers-and-it-equipment/emerson-liebert-nxa-30-ups

Dave

Matt, I can’t really picture your machine but, I do have one observation. Most of my gassifier is built with stainless steel. I believe that SS has 50% of the heat conductivity of mild steel. I believe that you said that your jets are SS. Would they run hotter, and burn more tar if they were mild steel?

I’ve built stuff myself for the free-energy applications. They REALLY concentrate on battery performance for trying to squeeze out better results. The accepted charge / discharge rate is the c-20 rate for maximum battery life. You discharge at 20% of the rated ampacity of the battery. You buy more batteries until your bank is big enough to NOT exceed the c-20 rate.

. Fully charged, they are about 12.62 volts. A surface charge may bring it up to 13 volts. L.A. batteries should not be discharged below 50%.

John Bedini put used batteries on a shaker table to break lose the deposits and then washed them out with clean water.

Batteries may be on their way out.

“Tests to determine the electrical property of the material revealed it

was indeed a super capacitor, and its 367 Farads/gram recorded

capacitance was over three times higher than graphene super capacitors.”

Thats a good question, i dont honestly know. I think Steves theory of the biasing is the culprit. The fix is really pretty simple, i simply welded in inspection ports today. I just zip out the plugs and look inside when its up and running. If i know the jet at the intake is glowing then all should be glowing. If not i have a ram rod i shove thru em. For what this machine is its good enough. I also changed out the hearth bowl and put a 1.5" restriction replacement.

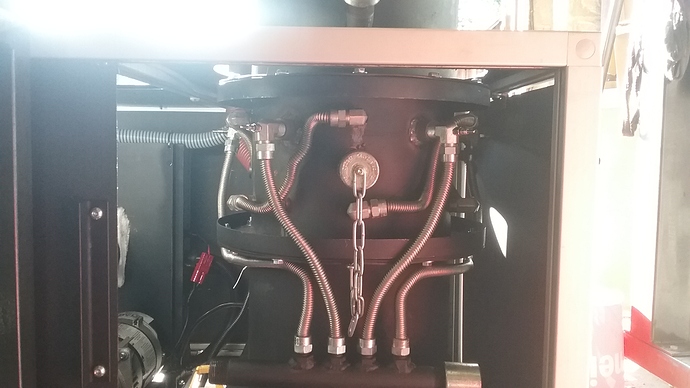

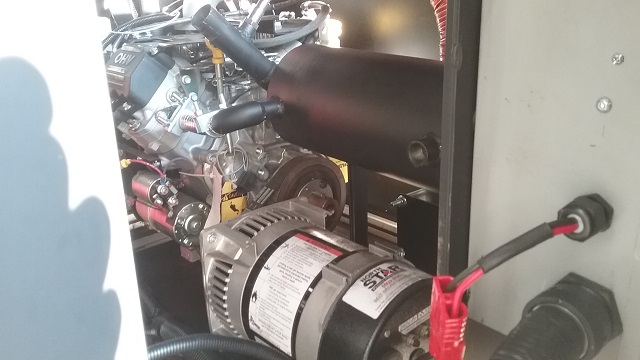

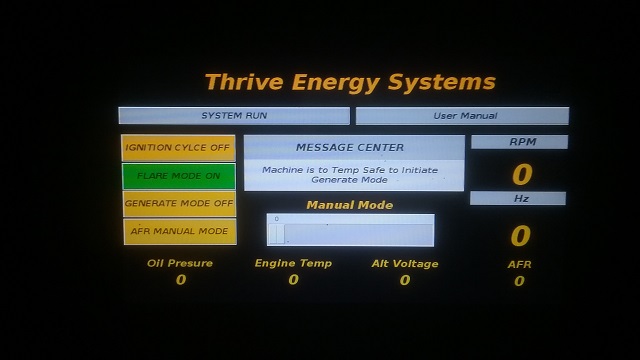

On another note, here is whats coming next. Sort got behind on this project with the move, but Im back at it and working on the electrical. I hopefully will get the electrical complete by tomorrow and can start electrical test first thing next week. This is the first machine with automation of this caliber, it has full automatic ignition, all valves are servo controlled and it has a semi auto mode and full auto mode. In semi auto you basically run in steps but is still automated where it lights itself, turn on / off the blower and opens the valves for you, once up to temp you manually adjust the air metering and manually initiate engine start. In full auto you simply initiate auto mode and it does all this on its own including starting the engine. Well thats the plan anyways  This has an exhaust CHP system plus you can tap into the Liquid cooling of the Kohler Twin. This will be the last auger fed system with a DC drive, next versions will have a much more powerful AC drive, should be able auger bricks through that one.

This has an exhaust CHP system plus you can tap into the Liquid cooling of the Kohler Twin. This will be the last auger fed system with a DC drive, next versions will have a much more powerful AC drive, should be able auger bricks through that one.

So today I think was a successful day!! Still many bugs to work out, but this thing fired all on its own today!!

Having the ability to fully interact with the machine via push of a button on a touch screen is just plain cool!!

I have a few issues unrelated to code and are hardware problems. There is a two channel timer board that is supposed to control the reactor ignition glow plugs and the flare igniter glow plug separately based on trigger inputs into this timer board. It was working and now for some reason it deos not matter channel is triggered both timers set activate. So no biggy I was planning to scrap them anyways and go to a 6 dollar controller with predetermined time sets. So Ill just implement this now.

Some code related issues are some interference with feed back loops to the RPi. The RPi reads these inputs coming from the Arduino Gasifier Control Module. When it sees a state change it then take this and compares to other inputs and then displays a message based on whats on or off at the time of this state change. I have double shielded cable and still having some issue. This is a complicated way to go about it, so I think I2C to the rescue here as well. Just got to figure out how to go about that one. But I can send simple number or letter and when the Pi sees this single input over I2C it have less confusion and just display a corresponding message.

Later in the day I hooked up my laptop so I could see what the GSM was seeing and executing. That was great help to tune the parameters so things are turning on when they are supposed to when temps are achieved. But this came later in the day after the machine was warmed up, so tomorrow I will start from cold start up with this and tune further. But first thing will be change out that timer board and I also need to install a solenoid to drive the hopper shaker. Its taxing the system too much so I need to isolate its power more direct from battery. Other than that I think Ill make it through this part. Once I have the machine firing off in sequence in this semi auto mode, Ill move on the engine controls. First will be to get it up and running on gasoline with your basic on / off switch from a manual panel at the engine. Then Ill wire in the controls that will be able to interview if the manual over ride switch is off. Then once Im that far then Ill move on to the automatic mode. But Ill really need to get that I2C code working before this as this also drives this part of the code.

I didn’t get time too read your entire post on this page, Though it sounds neat as being push button control in the perfection stages, What I was thinking when I clicked drive on wood is how could you post more flyers or advertisements in the Florida area, those poor folk, could stand too save a ton of money using your budget gasifier these days of mass power outages. I am going back too read this page now, later thanks for posting the update designs.