Here is an engine without valves. Need a redesign for woodgas.

I had thought of an engine design that had rotating cylinder with ports leading into the combustion chamber.

Mazda (Wankel) rotary. Owned a couple, run smooth but suck gas, plus older ones needed an oil drip in the carburetor to lubricate the rotating seals. Newer ones work better but still suck fuel. It is hard to beat a modern 4 stroke engine with electronic controls and fuel injection of some sort, spark or compression ignition!

For a few years, (2005 to 2009, I think) there was a bimonthly magazine (Model Engine Builder) that featured a different (historical) unconventional engine design (RICE, Real Interesting Combustion Engines) in every issue. I suppose they ran out of content, but they had a dozen or more of 'em in there.

I worked in one of a big company’s labs for many years and there was some sort of corporate policy that you could spend up to 10% of your time on just about any “wild idea”. Not too many people took them up on it. You needed a track record to get the “okay”. That was okay with me, though.

There were different levels of this support for that level of innovation:

The basic research scientists spent most of their time in that area.

Design and Development people in operating divisions spent less time on wild ideas, since they were usually tasked with producing product designs to meet a manufacturing schedule.

A mechanical engineer in my division did try an engine design of his own, but it didn’t really go anywhere. The basic engine design idea, as he explained it, is, that if it will work as an air compressor, it should work as an engine.

Pete Stanaitis

Hey there Mike, I prolly should have described it a little better. My concept idea is still a reciprocating piston engine engine. The change is in the head with a rotary valve set up. This is what I meant about the rotating cylinder. Basically instead of an over head cam you have a tube with ports in it. As this rotates with timing these ports would line up with intake and exhaust ports of the head. The issue here is you have less control of the opening during the duration of the stroke. Where as a cam lifter set up you have better control over the lift and duration of the valve. Some of this can be overcome with the geometry of the opening. The ports would look like a slot vs a round hole. To be able to change this alignment vs the piston stroke is when we would get into high end servo controls to snap into alignment and then get out at the end of the stroke. I think this would be a better system than what the manufactures are trying to do with linear actuators.

Ha, if l culd find a skech from my highscool dayds! Its basicly the same concept you described. But Max wuld say “there is nothing new under the sun” and such a system exists already.

My Mercedes has the same kind of idle control valve!

In my bored to death highschool days l gave a lot of thod and skeching to come up with a 2 stroke engine wirking without premixed/injected oil. The pros of 2 stroke engines are obvious.

Well Steve we do both, this is now an added insurance policy and not hard to do at all. Id rather offer it than not. Not all customers take us up on training most take delivery and I never hear from them again. It sucks I would rather get input from them good or bad and to be able to aid in training. All gasifier plants have the potential to produce tar especially for new users. Sort of like sending your teenager out for there first drive. Every time you get behind the wheel and out on the road there is potential for an accident; no matter who is at fault. This system is there to aid in training and an added insurance policy. My efforts are done with it, it works no need to continue on with its development. I will certainly try other lubricants but the grease is working just fine, ive yanked an pulled on that intake valve for the last time.

Yes the new controls systems have a temp probe at the grate. In order for the user to be able to enter engine run mode the temp operating parameters must be met. Also if the reactor temps drop the machine will also automatically shut down on its own.

Edit: So yeah spent the last 6 years trying to figure out how to keep an engine running on woodgas and now we are trying to figure out how to make it stop. haha

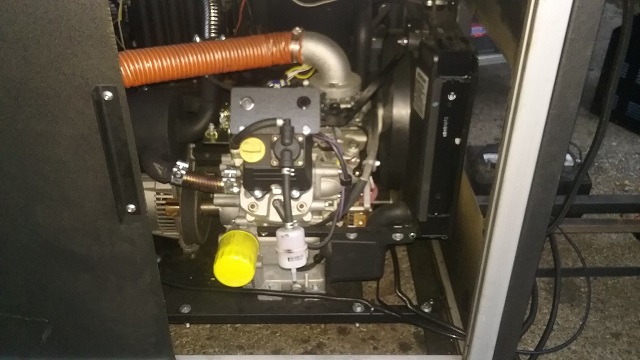

I am going to try using a KnN filter and see if its passive enough. This current Evolution would be the perfect machine for this. But its already set up and we can not put much more time into it. I have a lot of run hours on it from its previous revision with the older controls and Predator twin. It was very rock solid and made really good gas. This machine now has the Liquid cooled Kohler and the new controls.

I just fired this Kohler up today on gasoline for the first time. This is the first Kohler Aegis we have had since the one we built a few years ago. I absolutely love how this engine sounds, especially just idling. It has this wild cam sound to it and rumbles better than a Harley.

I am now on the final stages of setting up the controller. I can get it to fire up the reactor, move into flare mode, it will auto light the flare and then it will display when everything is to temp. Unfortunately I cant get much past this as the batteries I have are shot. All good ones I had are in the battery bank!! We have been low on funds for the last week, but a new round of funds should be available as soon as tomorrow. Im going to get the Harbor Freight Big daddy of chargers first thing.

During light up of the reactor it is pulling nearly 50-60 amps during pulsing of the igniter plugs. This is firing all of them at once. Next machine I am not going to do this and fire them one at a time. This will require a controller to do so. So this will have its own separate control box. So that should help.

But today it cycled through everything pretty fast; it is a pretty cool machine.

Even though I was stuck at Harbor Freight for about three hours with a failed fuel pump. Today was a good day. I wish I had that gasifier set up in there it would not have mattered then.

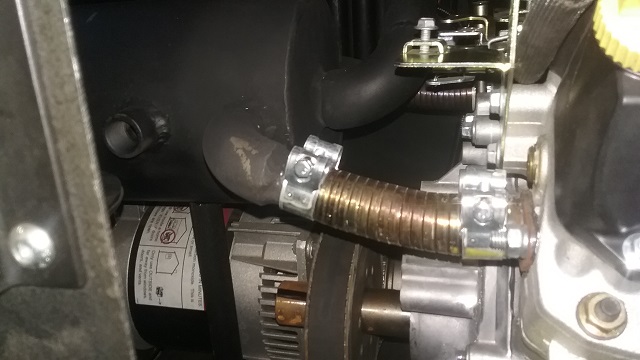

So the thing I was after was getting that battery charger. Once I got back to the shop I hooked that thing up didnt even bother to assemble it; just hooked it up and fired that machine up. Had a few parameters to adjust and went right into engine run. I ramped up the RPM’s a bit and it sounds like there is a V8 in there. Might sound different with out our other generator running but it sounded pretty good. However, there is an exhaust leak where our CHP connects to the engines exhaust outlets. Im using a flex pipe to make this connection as vibration was considered. I feared this would be an issue with the loose fit it had. Im going to trying and use our ceramic tape to create a better seal. Engine ran great, but it looks like there is one last issue when I switch into auto adjust it does not seem be self correcting like its supposed too. So I need to investigate that tomorrow. So hopefully Ill be able to iron out these last issues and get a camera aimed at it and get some video of it.

Ok exhaust leak is fixed, my step Dad had some hydraulic clamps in 1" perfect size so I gave em a try. They worked perfect and it looks much more professional than those ugly U bolt clamps that were on there.

Entering Auto-mode was a simple code tweak I had to make. In the bigger picture of things, this will be fully automatic and to control the engine starter in this mode; it will use a knock sensor to tell our starter to turn off when it detects engine fire. I had a condition that also had to be met in order for the controller to go into auto mixture adjust mode when in the full automatic run mode. However, I have decided to slow this down a bit and just get this semi auto mode working first. So the Knock sensor is not set up on this so I had to eliminate it. So I was successful at getting it to switch into this mode and this basically concludes this portion of the controls. This will be the first version and we will build up from here. The O2 code has also been tweaked a bit with switch case methods in code writing. It is much more responsive with out hang ups, I cant take credit for it nor can I take full credit with the other software. A mutual friend of one of our member here on the site has been a great help and launched me about 2 years in code development. Could not have done it with out him.

So I set up the RPMs as well today, the engine runs at 2400 rpms with 3600 rpms at the generator. So my math worked!!

Now it does sound more like a twin engine with out all that noise and shutting off our generator so I actually here it. Still a cool sounding motor though.

!

!

To run on gasoline this is a simple control to turn engine power on and engage the starter. The fuel line hanging down I plan to install the smaller quick connect couple and you basically shove a hose down a remote gas can for the diaphragm pump to pull from. Our controls are also wired into this and will override them when off.

!

!

Well tonight was the first run under auger feed since it had the predator earlier this year. The new 02 code worked perfect, it lobed at first and then stabilized as the machine warmed up. This is good it did what its supposed too and kept the machine going. Once it stabilized it ran solid for over an hour and with out even a hic up. It just ran and ran

Ok so there are some code tweaks I do need to make. It is temp sensor driven and these parameters need to be met solid before you can go on to the next. So the way it is now these temps get hit and then drop during the transitions. So the code alteration is simple I just need to write a variable once it hits the target and then this variable is set and can not fluctuate.

So taking a break tonight, Ill make this alteration tomorrow and if the weather cooperates I might get a chance to get this thing on camera.

Not quite ready yet, the clamps loosened up after they got hot, so going to custome make them tomorrow. Argh!! That little bit of noise is annoying and to others it would sound like a mechanical issue. Sounds like a valve ticking type noise and is a no go to put on camera. So Ill get through that.

Other than that fuel is not dry enough, first batch only dried for a few hours. Still a bit wet, so I have about 12 cf out drying on a tarp. Im probably going to give it few days to make sure its good and dry.

I ran today and set up the new code but like anything else I do there is always some sort of challenge. It would not see when the flare lit under the new circumstances in the code. So changed this, changed that and after doing this for a few hours I finally found it. That parameter needed it own condition alone in the code. I had set up along with the other sensor. So by the time I got done messing with this I had burned out the combustion and reduction zones. Had to re burn it in and in this process during some engine running fouled out the plugs. Pulled them out cleaned them and thought I had it all good to go. When I finally was able to engine run I thought I had weak gas. Later I found when switching to gasoline it was running on one plug the whole time. So tomorrow I will get a couple sets of plugs, build those exhaust clamps and get a throttle cable as this has a screwy governor set up. I need to tighten up the belt I think as well I figured it might stretch a bit. For now Im just going to run on gasoline for while and learn this machine running on gas first. Then once the fuel is dry I will then know what to expect out of it. Right now Im running off grid on this machine  .

.

Ok video is uploading should be ready by the time we meet at Argos next year haha.

Still having some issues with this stupid governor on this engine. It has a few different placements for the tensioner spring so Im going to put on the most torque the arm can apply to it. But its such a stout spring I doubt it will do anything. It might as well have a solid rod connecting it. So going to fiddle with that today and may need to order some springs to try and tune it. The inverter when it applies the load it pulls it down and the throttle does nothing to intervene. Even running on gasoline it has a hard and lobes as the inverter applies a varying load as it reads the voltage. Other than this issue the machine is doing whats its supposed to video went well.

Here is a link to my customer in Australia he did a nice job for me on this.

Excellent satisfied customer video. Make a good commercial TomC

I now see why you were working on the grease for the engine. Typically, a new person to wood gas and look it the tar he created by not understanding “dry” wood

Hi Matt , we have a couple of guys here interested in a wood gas units rather than charcoal ones that we use ,I notice your customer looks like a close neighbour to us , so you would have a break down of costs getting them over here already I would imagine , if you can get in touch I will let these guys know that one of your units is already over here .

Cheers Dave

I prefer international customers arrange their own shipping this way cost up to them and they pay direct and it just makes it all much simpler. Im just a middle man when it comes to the shipments. So with that said they pay the same just as everyone else and can purchase direct from the site. However the flat rate shipping that is set up for US shipments is still valid as this covers the crate cost to ship abroad. US shipments just get a pellet and shrink wrap. We used to build full crates and only 50% made it too destinations with out some sort of damage. So Im thinking why are we putting all this effort into building crates when it does no good anyways. Started just shrink wrapping and now the damage has been reduced by a lot very seldom is there an issue and typically very minor that our customer cant fix.

For the unit Jacob has I think it was around $800.00 Ocean freight and then your tax duties at customs. You might want to reach out to Jacob and he could fill you in better on the cost, I did not set it up.

Yeah he said he is going to try a different species, he is using some sort of pine. So he is doing good with it and is learning what wont work already with out even trying to run an engine yet. So this is good.

Hi Matt ok no worries If you can send my email address onto Jacob for me that would be good , so I can have a chat to him .

[email protected]

Dave

On this governor I set up the spring in the new location. It has five spots starting at 1 on up to 5 positions. But there is one before the 1 and at first I thought it was a 0 but I think its actually a G. (Generator maybe?) So thats where I have it and it does respond but I still think its too stiff yet. So Im going to see if I can find some alternatives to experiment with. It just is not responding fast enough for the inverter.