Ok Im not sure what the deal is but I think I need to look at the generator as the issue. Im not sure yet and need to tear into it and see if it has an AVR. My bet is that it dont, I have an old generator that has one this size so Im going to investigate installing it. This engine has plenty of power running on either wood or gas and should be able to pull this load no problem. The predator 8750 we can do it and runs most of the shop on woodgas, needs help when we run the CNC but I can weld. There is no reason why this engine should not be able to supply the load. The inverter has a range it sees as soon as it goes outside these parameters it cuts off and then back on causing this lobing issue. So back at it!

Ok nope it dont it has some sort of capacitor but I think its not cutting it. Its stupid my little 4000 watt that hardly runs works just fine running that inverter. So anyways Im looking at some universal AVR’s on Amazon, Im awaiting reply to some questions about them.

Anyways that video finally uploaded. This the EPS full auto!

Matt your systems are way above my pay grade but the oscillating genny thing is familiar to me. We always solved it by adding a 100 watt light to slightly load down the genny so it’s not searching. It gets hooked up seperate from the inverter feed. Even a lot of really good gennies would not be registered by the inverter or get kicked out as out of spec when the load changed too abruptly. They lock in to this weird feedback loop and nothing gets charged. Just a thought.

Cheers, David

So I just need a slight load in between the inverter and the genny? I have a battery charger hooked up the 110 output but may not be enough. I did notice one time when we loaded down the inverter with our air compressor while under load from the inverter it smoothed right out.

Exactly. Just make sure the small load is not rinning through the inverter but seperate straight off the genny. No promises but it is a recurring problem.

Just to clarify on the issue. The genny runs quite smooth until the inverter slaps the load on it. Then it just drops. the engine tries to recover and will either over rev or the inverter will yank it back down. It either goes beyond the upper or lower parameters. Im going to go out here in a minute and put it back to gether and try loading it down and see if I can get to behave.

I’ve seen everything from a 60 watt incandescent to a 500 watt halogen work light used. Anything consistent and on before the inverter charger clicks on

Ok for right now i have my small genny running the inverter. I decided to throw a load test on it and it hits a 3000 watt load with out a flinch. So really annoyed now haha always something!!

Matt I tried looking back but cant see a mention of the type of inverter charger and what size it is , are you running this inverter/ charger from the old style generator or one of the new inverter generators ?

David B i have always had a surging problem from my small inverter generator when trying to charge up my bank from 50% DOD, so in a few hours i will try what you mentioned to Matt and see if that helps with my problem also

On the gasifier front i have a confirmed order for 1 unit so far and will place an order with you as soon as i can find out shipping costs to Victoria Australia , i will also need to find out what port is closest to you,

Cheers

Dave

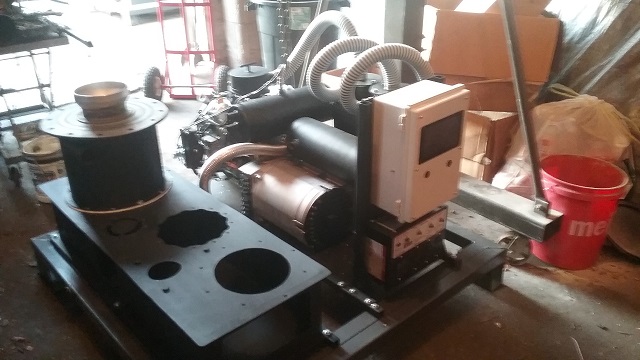

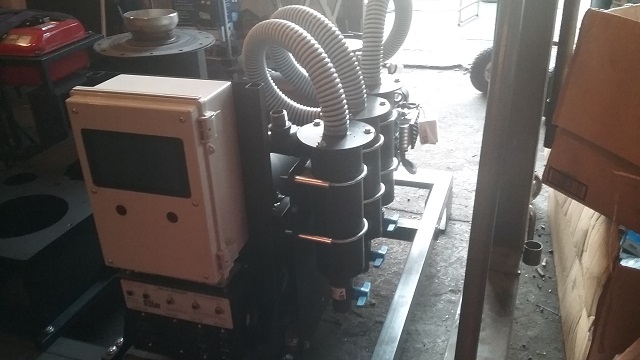

Everything is new, the charger inverter is the AIM’s 12 kW and the generator head is a North Star with Capacitor voltage regulation. The later is the problem, In my case I think the fix is going to be just ramping the machines RPM’s up to 2800. I may need to add moment of inertia flywheel as well. I found some larger gears that could be used and will be able to use them as an exciter ring for an RPM sensor. So when you look in there you will say thats a gear, and Ill be like no thats an exciter ring its designed that way.

I put a new gear on order to gear it down a bit. This will put it at around 2800 rpms. So a little more power and a little more momentum. If it still has issue then Im going to order the 8" spur gear. Its 1 1/2" thick. I do plan on adding the 12" on later machines but I will need to make some revisions to make it work. Too late on the ones in progress.

So once this gets in Ill get it on then measure the belt and get that on order. I hate guessing at belts I never get it right so just going to wait.

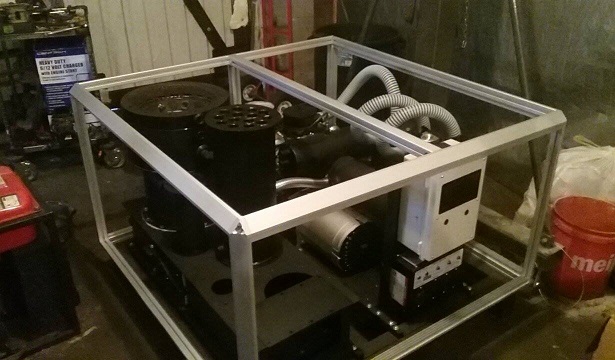

Well this is it, 2018 Evolution Power System in progress, this machine and the Utility for this year will both enter into commercialization process this year. All changes are final for the most part Im sure there will be some things that need fine turning like adding the inertia flywheel. But for the most part this machine is done we are done fixing it  Hope to have the gasifier done with out hopper and the new style enclosure with new paint scheme installed by the end of the week. Ive heard that before somewhere hmmm

Hope to have the gasifier done with out hopper and the new style enclosure with new paint scheme installed by the end of the week. Ive heard that before somewhere hmmm

We are also moving once again, this shop has served its purposed but time to move on to bigger and better things. Im looking at multiple large facilities and will secure one of them by the end of the week.

Matt,

I read that e-book recommended by @Jeff. (2-second Lean). I liked it a lot. One of the example companies puts everything, even the Boss’s desk and the lobby furniture, on wheels. I think that would help your spontaneous mobility!

At least it will be a larger space…

I bet Matt takes his turn cleaning the restrooms…

More than my share thats for sure!!

Not as far as I wanted to be, but its on there. This the new frame we will be using going forward.

Hi Matt, looks great! I was just wondering is how clones do you have working for you. Boy you sure can crank out the products you are making. It would take me all day to cut the parts out, with the mistake cut parts included.

Bob

I wish i had a clone, this is week 7 on this build and we are now three weeks past due on this one. Technically it should take three to four weeks to manufacture an EPS and two weeks to produce a Utility. We will get there once all the documentation and file system is complete and set up. Helps to have a CNC machine to carve all our parts out, it dont make mistakes.  We have our work cut out for us as the machines are getting all new G Code files while we set up work orders for each individual section of the machine.

We have our work cut out for us as the machines are getting all new G Code files while we set up work orders for each individual section of the machine.

These next gen machines are going to be beautiful

!!

!!

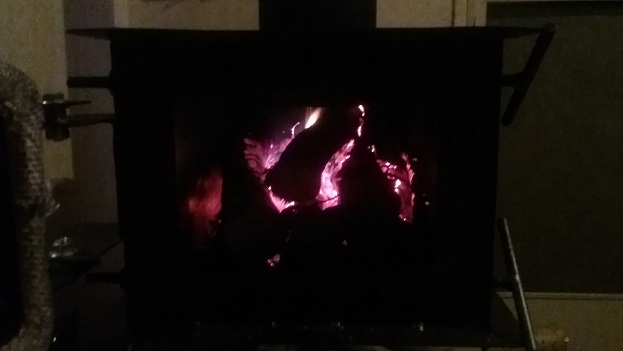

Cranked out a quick side project. Ive been wanting to build a new version of the pellet fueled rocket stove mass heater and since its getting plenty cold, I decided to get to it. One of the pre reqs for this new version is I wanted to build a traditional fire box for it so it could run on either pellets or like a traditional stove. So that got the brain re inventing some things and now it can be set up as a stand alone wood stove with a true combustion heated hot plate, secondary combustion with duel damper controls and double wall construction with ceramic filler. So this is basically a very advanced pack stove that ive designed the rocket stove into as an add on. This will also have an add on for a small bolt on oven later as well

So anyways I whipped up this design yesterday and set up all the G Code last night. Got up today and busted it out. Considering Ive built quite a few of these small stoves this thing has a pretty good burn time, I fired it up at 7 pm and it still does not need any fuel yet Its 1030 now. I have very good control over and can crank it down and so far it will sustain at the low setting.

So once I find time again Im going to build the pellet fuel reactor and this will bolt in place of the hot plate, revisions for this already exist. Then this will get the rocket stove tower, I can do this on this stove the way it is with out the pellet fuel reactor. This will most likely get a hot water heater coil wrapped around it.