I like it Matt, but that doesn’t look anything like you.  That dude has no electric guitar and Metallica T shirt.

That dude has no electric guitar and Metallica T shirt.

Hi Matt,

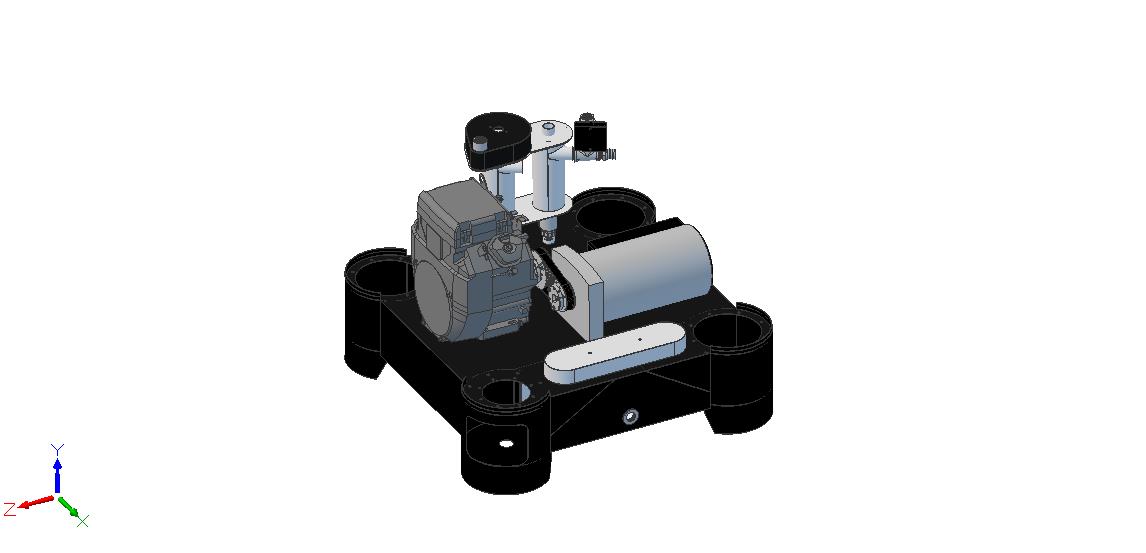

Very interesting design regarding 360 degree access to components. Do you have an eta to when you are rolling this out for marketing, and a price? Would this unit work well or as efficiently if only supplying say 5-8 kw demand? I assume this is still a pellet only machine.

Hi Robin, the machine is currently on the market and is available now in many outputs. Plus I am offering a kit version. I am currently working on four of these machines right now as we speak. I hope to have the first one ready for demo sometime in April. I dont want to jinks myself like last time, but I most likely will have one at Argos this year.

Yes I have gone to pellet fuels as standard, I will never ever, ever, ever ,ever, ever built another chip or chunk machine again. Hahaha. This pellet reactor technology is just way better technology and its lower cost more than justifies the cost of the pellet mill. The pricing on a comparable chip machine is less than half the cost.

Pricing for the base kit is $5550.00 and the 12.5 kW version is something like $14,500.00 then there are the mid range machines that sell for in between.

The 8 kW CHP is the Cadillac as this one features the Liquid cooled Kohler. It produces 8 kW continuous electric output with an estimated 60,000 btu heat output. This tiny little machines combined energy output is something like 25 kW

You can see all the listings here. click on the “Flex Power” button and a drop down will appear for all listings.

Thanks for the update!

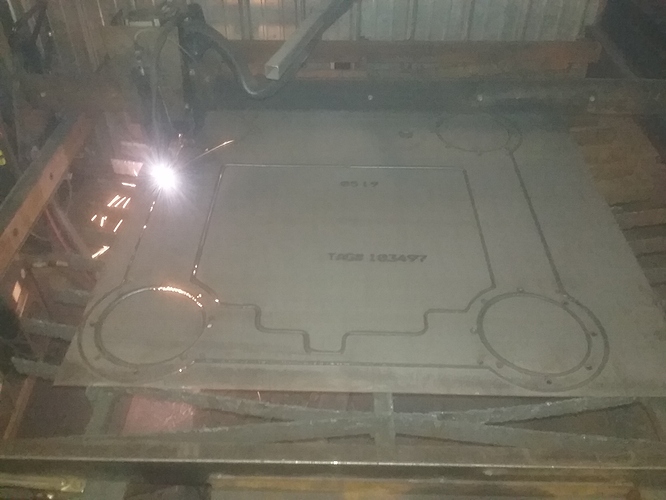

Yeah as soon as I get a new camera Ill be fludding this thread with build updates. Im pretty excited about this machine. Generally I make small steps in design evolution. This machine is many leaps

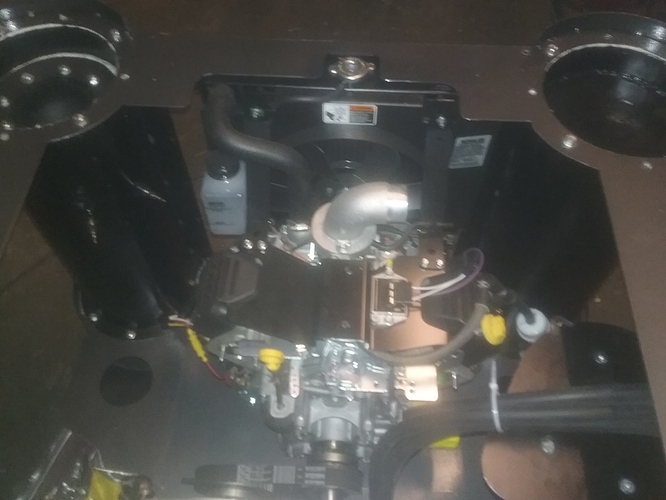

I got the Kohler in today, so I threw it up on the base along with the gen head to see how it fit. Its gonna work just fine

Still a bit of work yet to finish the base. I forgot to order weld nuts for it, so I can not weld up the bottom plates until I get them in. Need to weld in some support bracing to hold the engine and genny in place and then for this Kohler I will need to relocate the mounting holes back 2 inches. I figured Id have to do this. One of those things where you need the parts first before you design.

Is the drive a cog belt?

Yes, the drive is 1" wide HD timing belt system. I used V belts in the past and they slipped and burnt up. These dont slip. lol

Nice looking base! I’m getting ideas on how to mount my gassifier. Thanks

Rindert

Hey Bob,

Yes! This design could be scaled I think in a few ways. This reactor is unique where I could build a larger unit with an array of these cores that could share a single reduction. Or I could simply build it bigger. However there are limits to the sizes available of those cones. Each reactor core should be good for every 1000 cc. So I think most V8 engines I would need to build five cores in an array. Yeah Im way ahead of you been thinking of this for a while. Only one of me and only 24 hours in a day

Matt,

i 'll try to put it in one 3 letter word what i think about you and your work;

WOW ( in the most positive sense )

Sweet! a very good looking design.

Yes you sure do build quallity machines, Are the four corner pipes doing something differnt, filters, fire tube ect.? i problly missed it earllyer.