If you are putting in hot enough air, you don’t actually need to burn any wood to gasify it. You really just need the heat. The h2/o2 combo might be helping the water shift reaction. I don’t know. Usually all the brown gas stuff uses more energy then the gain.

Im not trying to gain with this. Im trying to reduce the machine size; the point is to eliminate the Nox and possibly improve gas quality. Not so much to make it more efficient. So keep this in mind.

However, some theory; and throw all the HHO stuff aside, this is different. A naturally aspirated gasifier will consume 30% of the fuel in process. This H generator is indeed much like a typical electrolysis cell. However it is replacing that fuel that would otherwise be used. This with the Hydrogen Plasma Reactor will be 100% controlled with a perfectly static and focused oxidation zone with out any migration. So the combustion process will be greatly improved. Wet fuel will not effect this combustion process; however, of coarse wet fuel will require more energy to process and will effect the product gas quality.

There should be some reclaim as the H is recombined with O producing steam at oxidation and then shifted back to H. There will still be some atmospheric air consumption in process but it will be greatly reduced. Because this will be very focused and well controlled this opens up steam injection here as well.

So now with this system, it should have 30-50% higher gas energy density, Raw fuel consumption is now much less, with trade off producing the Hydrogen remotely. The hydrogen yield should also be greatly improved.

When you think about this application you really need to consider all the dynamics involved. This is much different than any other application involving HHO. Think about the flows involved using atmospheric air to create the product gases. It needs to be a great deal more as 70% of it is Nox and it does absolutely nothing for us. Volume flows should be greatly reduced while making the gas much more potent.

Well my pretty blue flare was no where to be seen tonight. I think earlier in the day it might have been there. However, later in the afternoon, the filter plugged completely up. So that may have been why I was seeing this flare in the first place. This clogged up filter may also have been plaguing me at the show on top of the weak battery. So no biggy; what Im am trying to test here is if there is any added consistency but now have to test again. So far it seems to run pretty solid for a machine with no automation, but its been that way with out this re circulation mod. I think the real test is to engine run and see what happens, What I would like to see is a more open throttle. This machine is a bit different than any other machine Ive produced as well. Most if not all prior run with this same valve set up at 50% angle position or below. Not very often are they open beyond this. When this machine is breathing right the air intake valve is generally 80% open and I believe this is partly due to the added char reactor that is allow this.

So lava rocks are out of the filter and in the fire burning off. I think Im going to move on from this test to engine running with and with out the re circulation. Still going to build the H Gen regardless of what happens but still want to see if this is doing anything

Hi Matt, how do you clean your lava rocks. Are the rocks in boiling water in the pots and then burned down?

Bob

Nope just just drop em in the pots put em in the fire. They burn like charcoal, but dont put your steak over em

Take a look at this, I think this will be a much better solution vs electrolysis. I did some math and its 300 watts pr 2.5 lpm of 95% Oxygen. vs electrolysis 800 watts to produce. 0.83 Lpm pure Oxygen (based on commercial HHO torch spec)

The Hydrogen is not what Im after its the Oxygen with NOx eliminated. So instead of using pure H ill simply recirculate some of the produced gas back and mix it with the purified O for this plasma reactor system

I could not even come close this cost pr output of this machine… I did some research and this machine is the best bang for the cost. There are lower cost versions but are not very good quality.

https://www.amazon.com/dp/B07KNBTB9V/?coliid=I350JCOIEYIPTB&colid=Y42IIXJO6BCA&psc=0&ref_=lv_ov_lig_dp_it

Is that going to be high enough output? 5l/m doesn’t seem like a lot. Electrolysis isn’t’ that efficient so it seems like a good solution, but I would check to see how much the filters are for it.

Yeah the filters are pretty cheap. Yeah that is a good question I cant think of a way to properly test intake volume. But I think in this little gasser I am going to build for this, 5 lpm will be plenty. That would equate to a total gas / ox mixture of something like 20 lpm.

Looks like an interesting read, checking it out now thanks for the link

That looks like they are using enriched Oxygen for the gas mix and combustion. What Im doing is feeding enriched Oxygen directly into the gasifier to cut out the NOx from the gasification process. NOx will still form in process but should be cut down significantly.

Our produced gas in general is made up of 50% NOx.

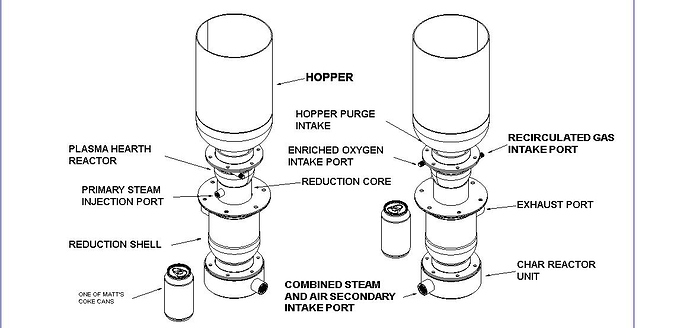

So I started work on design of the gasser over the weekend. There is more to add to it, a lighting port the hopper purge port and then the clean out. This is just going to be a proto, but the core of this most likely will remain the way its designed now. On the more developed version this will be housed in a corner pillar like the current FPS reactor and there will be an ash box.

So this has a plasma reactor system and will work much like a fluidyne system (kinda of sorta  )

)

So getting ready to wrap this one up. This is the very first one, so there has been many challenges to overcome on a new model build. I will be rolling back this model to one offering come September with a new simpler “three pillar” version coming to take the place of Non CHP models. This quad pillar design will become standard with CHP and the Liquid Cooled V twins. The Three pillar design, will have vertical shaft driven power units built inside for a more compact system. The auger feed will also be eliminated on this version, but it will still have an expanded hopper but will just be a gravity feed system.

Matt,

That is one really good looking unit!

Pepe

Sorry for the delayed response. I am not really up on NOx beyond I know it is a problem. From what I did see, it is from ammonia. In coal plants, they can take care of it in a secondary burn, if they can get the airflow right.

I think what you end up with is essentially a forge for a gasifier. Your producer gas is going to burn as well. You may have too much O2 in your hearth if you are getting that much NOx emissions according to what I read.

If it is ammonia, and my lame liquids attempt had ammonia smelling fumes to it, then that is easily absorbed in water. A water filter might do the trick, which would also cool the gas. A simple design looks like a moonshiner thump keg.

The enriched oxygen machine might be good for welding/cutting torch o2, while I am thinking about it.

What you seemingly keep inching towards is a fluidized bed reactor.

Just want to clarify the NOx elimination is not for emissions. The whole point is to remove the NOx from our gas to increase the energy density of our produced gas. A gasifier with this technology could potential be reduced in size by 2/3 of current machines.

This would have a HUGE impact on manufacturing cost and the overall size of the machines.

A few side notes, with the enriched oxygen combined with recirculated product gas, the gas flow rates should slow down a great deal. This should result in more dwell time inside the reaction zones for a much higher processed gas.

Yes the reactor is a fluidized reactor. Current reactors are like this now but I dont have the swirl jetting set up yet.

Oh! I think what you are saying is You are trying to reduce the addition of atmospheric N2 because it uses volume. thus adding only oxygen to the mix should improve the density of the burnable/convertible gases. That makes sense.

Usually a fluidized reactor uses a small particle size like fine sawdust so the heat from the flluidizing material, typically like sand, can transfer the heat instantly. The instantaneous gasification of the material gives a different results in the producer gases.

lol now you got it!!

As for the Fluidyne concept, it is only the flow that is shared and even so its not quite like a fluidyne system. There is a very small open chamber for the swirling of the gas mixer and then the fuel is at the core. So Im not even exactly sure what it will actually look like in side the reactor core. Can only try and visualize and see what happens.

Could you use a zeolite filter just before the carb to remove the nitrogen? You may not remove it all but at least a portion to see if there’s an improvement

Thats interesting Bill, However I would place this at the gasifier intake not at the engine. I will research this further thanks for the input.

I’m not sure if zeolite will filter only nitrogen or other things as well. The zeolite will ‘fill up’ with nitrogen but also is able to be removed and the filter can be reused again. I had discussions about this years back and someone thought maybe the firetube may get too hot or create other problems.

Yeah removing the NOx in the gasification process I think will change many dynamics in the process.

This is one reason I am planning a plasma type reactor with combustion coming from external sources and in a way where I will have full control. It may need to be done in way so the Oxygen can only oxidize what I want to burn “recirculated produced gas” I have a feeling if the oxygen is too pure it will actually burn the metals.

The only way to find out is to build, so thats where I will be headed.  .

.