Yeah Ive been looking at their products too, they make some good stuff.

Midnite is pretty much all we install for controllers. Outback’s flex units would be better since we can monitor them but they don’t have built in arc fault which we need by code here.

I was at a course 8 days ago and got to see this bad boy:

http://www.midnitesolar.com/pages/b17/index.php

lots of ul listings to go but its in beta. pretty…

The xw+ which is what I assume you are talking about has two ac inputs. I don’t know whether that requires 3 phase input from both the ac inputs if it is in 3-phase mode or not. The install guide could tell you.

With grid-tie, it is connected for a 2-way communication with the grid, so you don’t need batteries. For off-grid use, you can also draw power from the grid, but you can’t push power back on the grid, so you don’t need batteries. If you are not going to use the grid at all, then you will want batteries or else you have to run the generator all the time unless you have another power source like solar that can cover all of the demand, and you will still need batteries in order to cover the under voltage during the time it takes to fire up your generator and get stable current.

alternatively, if you are going to convert it to dc, you can run it into the solar input, but you will want a smoothing circuit which is what a 'power supply" does (or a bridge rectifier with a smoothing ie a capacitor) you can also boost the voltage with a step up converter/transformer or a boost converter if you can’t hit the nominal input voltage which you can’t do with single phase ac.

We are taking about two different systems. The PV system high voltage and then the XW+ that is 48 volt. The PV option would be less cost to build larger teamed systems vs stacking the XW. But we would lose the automatic run features as that would require full time output and there is no battery storabe system on the PV inverter set ups. The XW inverter can pump into the grid it is grid tie capable right out of box. Ive been in contact with Schieder representatives and have learned a great deal about the XW. It can run in bypass mode and is capable of more than double its output from battery.However, the XW does need a battery bank of some sort to function at all for some reason. The input is single or twin phase 240 volt and it will output in three phase on three phase inverters. I would assume this where the bank is required to make this conversion.

Same thing goes for the AIM’s this inputs single phase 240 and automatically outputs in twin phase.

Matt you are correct that the 3 phase has to come out of the battery bank. I would guess that in a grid tied system the inverter would be able to take ac off the grid put it onto the 48 vdc bus and pull from that same bus to generate the 3 phase ac so in effect the batteries would be little more then a buffer for inrush current.

As to using the pv charge controller idea. I would ask a few questions of the manufacturer first. 1 can the generator input accept dc voltage? Can it accept a different frequently or voltage?

I have used alot of large motor controls in industry and one common design is just to pump the input ac directly through a diode bridge onto a dc bus. I don’t think schneider is doing this only because they have the ability to use the genorator input and grid input to boost the output current so I am guessing they actually match the input ac waveform with their inverter to boost power. Infact with the grid input they have to do just that to sink with the grid. Genorator input could be a different story. If the generator input will accept dc or a wider range of ac voltage or frequently then you would be able to use it. Explain to them that it is basically the same as a wind mill.

As to the auto start. I would be willing to bet that the inverter can be programmed to trick that function to work even if you use a separate dc charge controller. The invertor has outputs you could use and there are some good add on modules. I have only looked at the website which doesn’t provide alot of insite to the details but I would be shocked if you can’t do auto start and used a dc charge controller if you need to go that route.

On the PV inverter, we are basically mimicking solar panels with rectifying the AC output of the generator to very high voltage DC current like the solar array would output to the inverter. This is a huge range some are down to 380 / 1000volt range and some are less. The inverter just simply cuts off that input if it dont like it and will switch back and forth between grid supply or the solar array supply.

Yeah Schneider has so much to offer that using the website is a bit ridiculous. But the info is all there, you just need to pop a few Excedrins and dig away. lol

Here is the data sheet for the XW http://cdn.solar.schneider-electric.com/wp-content/uploads/2017/03/Conext-XW-NA-Hybrid-invertercharge.pdf

Here is the PV String inverter data sheet http://cdn.solar.schneider-electric.com/wp-content/uploads/2017/03/DS201703_Conext-CL-60_Eng.pdf

Here is the data to make all the Contex range of products work together. http://cdn.solar.schneider-electric.com/wp-content/uploads/2016/07/Conext-XW-Multi-Cluster-Power-System-Planning-Guide-975-0648-01-01_Rev-B_ENG.pdf

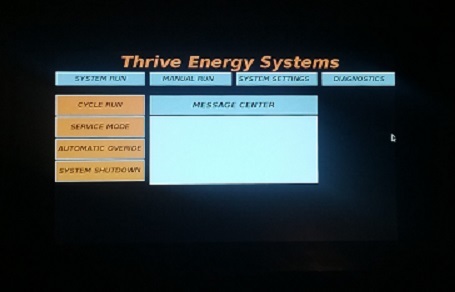

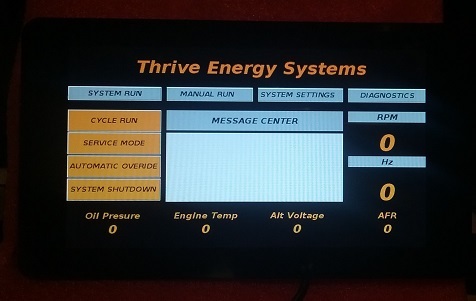

Next generation controls are looking pretty sweet, not bad for a novice huh? Lots more to do, this is just the first page and there is some input info I need to create yet rpms, oil presure and stuff like that. You guys that would be willing to help this is Python using tkinter, I could certainly use some if anyone is willing. There is a lot of info but some stuff that I want to do I cant find the correct info might not even be possible, that might be the reason who knows. But for instance using a scale or slider to output from the GPIO like a pot there is nothing out there.

So anyways this thing is pretty cool, Im probably going to add a menu so it has a user manual embedded directly in it

Browsing through the literature i see why you are going this route. Its a much larger higher voltage architecture then I’m used to. The’ve more or less left the home scale off grid world obviously after the bigger fish.

Best regards, David Baillie

Yeah those voltage are crazy high. For us on larger scale systems we need to follow and adapt. Small scale not so much but we need to the ability to transform a single product to fit the diverse market to stay in the market

Home page is complete now on to the next page to create the manual run functions, settings controls, and the diagnostic page. It will will have the user manual, model and serial number and other info embedded into an info page accessed from the settings page.

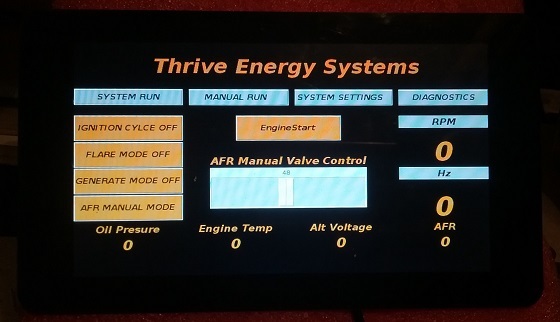

Here is the manual run page, the term manual is used loosely here compared to today’s standards. This will still be very automated this is only breaking down the run processes into four modes. Ignition, warm up/flare, engine run/generate mode and shutdown. This gives the operator more control for trouble shooting and learning and this can be switched into on the fly from the full automatic run mode.

Now for a truck system this is the interface we will be able modify and use. This will give you full control of the gasifier from inside the cab including starting it and shutting it down. The AFR mixture control could be set up to also control the fuel pump. So you get in your truck, turn the key, take off in gasoline mode, fire up the machine while you drive and then once up to temp; you gradually feed in the gas while it simultaneously reduces fuel presure until you are 100% on woodgas.

Hi MATT just would like too know what size truck you can run with it or how many units too run a 4 cyl s10, or is the gasifier done ready for sale, i will refer your unit once i know the details about it, Thanks.

I am speaking in concept we have not built a machine for a vehicle and i absolutely zero plans to do so with the exception of my own vehicle , Our Evolution S4 plant could do it with some modifying but its also an $18,000.00 gasifier plant I dont there is a market for it. If I were to put this in a truck it would be a project just like all of you are doing.

Ok Matt sorry for mis under standing the the reading, I should have never passed my reading class.

Haha, no worries Kevin, we all on here have our short comings. I have taken college level writing classes,and did well in this. However, as I age and…well maybe from sniffing too much woodgas; I miss half the words in my writings. The post you replied too is a perfect example of this and spelling; never was good at that, luckily we have google for that now.

New video, here is five years of development. This machine is finally done!! This will be last design revision for this machine for a very long time. We will move on to other development work but this will be on the Flex R1 version of this machine. Some of those developments will come as bolt ons to this machine later. But the core design for it is complete. The Chassis is more streamlined and beefier for this year, the ignition port is now built into the air intake, it has a removable and replaceable reduction bowl, it can be set up for wood chips or pellets as optional, and the blower is now direct pass through. If it had any more thrust I think it would blow over lol