Now your just plane old showing off !

Ok just conclude that run with three units and I got 2 hours and 55 minutes. I was a bit reserved on the water drip this time. The water drip was a little more finicky this time but I think its a matter of learning. It ran great for the most part, I went out to fill the water tanks about 1 and half hours in and they were only half full and once I messed with the caps it took a bit to get it re tuned in. Next time Ill just wait for them to run dry only deal with that if needed. Total water this time was only 6 liters and that is over this near 3 hour run, so much less H2 production.

Next is to boost it with the blower. I may re jet the units when running three at a time as well. I think with the three I maybe under driving them; But still a good run and proof networking works.

Charcoal plus water sounds like the perfect combination and so controllable vs raw wood. You basically take more water out of the wood than necessary with the charcoaling process and then reintroduce just the right amount of “missing water” in the gasifier for best effect.

I know charcoal production is a solved problem for most but I still want to fiddle with a running engine exhaust through sized but raw wood. I want to see if that amount of heat treatment and drying gets close enough to charcoal. Less water would be driven off with exhaust treatment than charcoaling but perhaps enough? Perhaps enough that a little water added back is still beneficial. If that’s the case you could still use water to control and richen the gas mix, though almost certainly over a smaller range.

In my mind’s eye I have a sealed chute between the bulk wood storage and the reactor. The chute gets a concentrated blast of exhaust running through it that skips past the reactor and storage area. Dwell time for the wood in the chute vs exhaust exposure would track pretty well. More dwell time but less exhaust if the gasifier is lightly loaded and vice versa.

Hi Anthony, your first paragraph is right on.

The exhaust gases have a lot of moisture in it. It can not turn raw wood into charcoal. Some have used it to dry really wet wood some what. You need dry hot air to dry wood quickly.

To turn it to charcoal it needs to be cooked or torified by hot heat in a container and the moisture is aloud to vent off and the gases vent off also with the tars in it. Then you have charcoal and not brands or half baked wood.

There are some Down Draft Charcoal Gasifers that can run on 100% charcoal and a mix with some wood,

Bob

I will expand on trying to dry wood with direct engine exhaust.

I plumbed the exhaust from my wood splitter into the bottom of a 55 gallon barrel that had a 4” high screen and about 35 gallons of green chunked alder.

After about 2 hrs of run time all but the lower 6” of chunks were DRIPPING wet.

Until the wood is heated to above 212 degrees F the moisture in engine exhaust condenses on the cooler wood.

You can also see this when you open the hopper of a gasifier before it reaches 212+.

Mike, your experience with condensation was exactly what I was trying to avoid by treating only a portion of the wood at a time in the chute. That chute would be well insulated so that exhaust heat is going into the wood, not the surroundings.

If you try to treat too much wood the exhaust temperature drops too far and all the water condenses out. The key is keeping the temperature high enough that it doesn’t condense and that means having the exhaust exit the treated wood above 212f, yes.

Steam drying is a thing. Same idea here… you just need to keep the temperature up and it will dry the wood.

It’s possible that engine exhaust is too wet and “cool” to do the job. I have some ideas to address that but they are more complicated. I would give direct exhaust heat a few different tries before moving on to adding heat exchangers and the like to raise temps and/or dry the exhaust first.

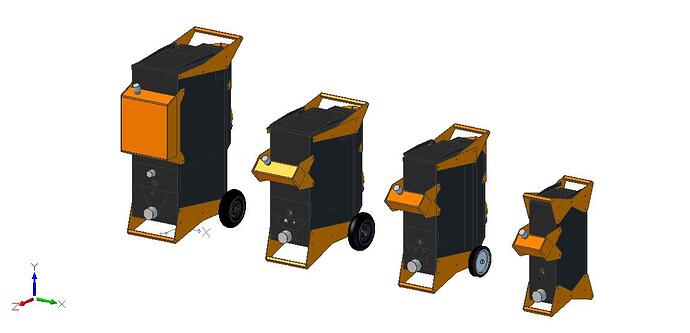

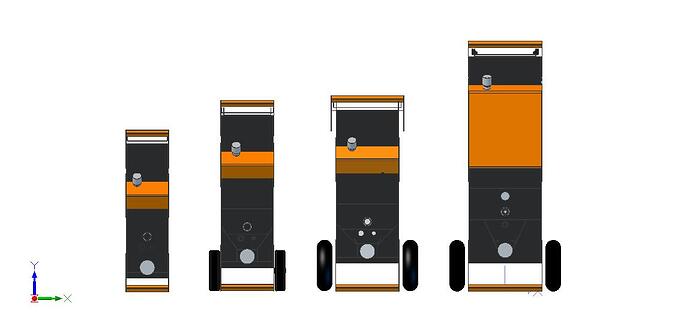

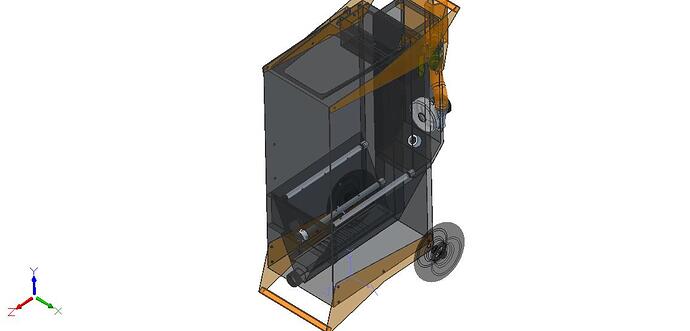

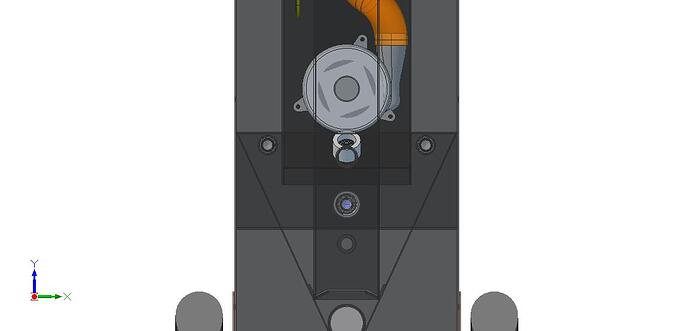

Ok it is now 1 AM, Ive been working the CAD design for the new M-1 Alpha all day until now. Just few more minor details but Im done for the night:

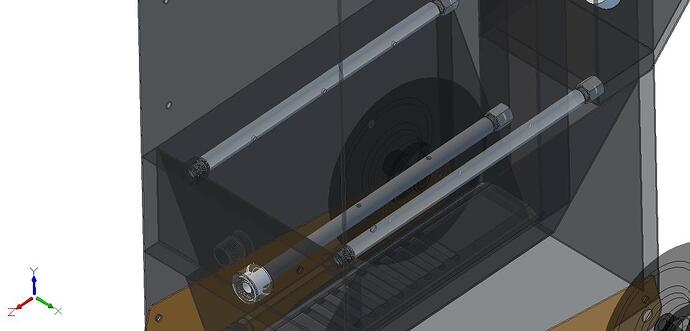

This first version will hopefully be mine to experiment with and it will have the double flute design with the center Evap tube. If it works all is good. If not all is still good as I can just revert it back to the open nozzle.

The water feed tube will extend inside the evap tube to its mid point. This is so there can not be any biasing. The air jet tube has three jets and this evap tube has two. The two steam jets are placed in-between each air jet. The steam depending on velocity should extend up higher than the air jet tubes or about even and saturate the fuel prior to it entering the oxidation zone.

This thing I about as big as I can build them in this single weldment type design. In a few of the pics Ive put it next to the other versions. The next smallest is the the M-1 Ute and you can see how much bigger the Alpha is. I am hoping to be able to team two of them for truck installs.

Alright, I am working on a new DIY no weld gasifier, I will start a series on my forum and possibly Youtube. I might just do video after it is built and outline the build process on the forum. Should be a fun project, it uses the shorter ammo box Bruce S has used The idea is to make a very small but functional unit that is easy to build without need for welding.

That should appeal to a lot of folks

Looks like your shop is filling up with a lot of short round fellows.

The water drip should have a valve controlled by engine vacuum .

I should have listened to you about capture of heat from exhaust .

I am going to do that . I have already converted to do that but did not realize it or how easily I could do this .

Tutorials here, the second one maybe of interest as I am playing with a new jet nozzle spin off of the flute design and my new evap concept. But in a single jet system.;

As usual Matt, you are doing top grade work. Looking forward to the hot bag filter.

Bob

Fantastic Matt , i think with the ease of getting hold of ammo containers i can see a lot of people building these for them self’s over a weekend , i cant wait to see the rest of your build and the test runs and i would really like to see how your new evap nozzle holds up running your generator for a few hours , would love to see some before and after pics when you get a chance .

5 star build as always .

Dave

Nice. Now I can quit messing with mine and just have my friends build yours. Wondering if that ammo box will get so hot will you have to change the seal on the lid.

We will find out  I have no idea if this thing will even work!!

I have no idea if this thing will even work!!

NONONO yours is neat in it’s own right and might be cheaper too. But I will say Matt has a talent for making things that look really nice and neat. ![]()

Utz (I think oem’d from chicagotins.com or atlanticcan.com) makes a 3.5-6.5 gallon popcorn/clambake tin with various logos like US armed services that would complement the ammo box design maybe for a cyclone filter. ![]()

Well Im pretty surprised how well this thing actually worked. I think I have the jet nozzel system Im going to use going forward. This worked quite well, I run it more.

I think the 212 cc engine is a little too big or is at least the very maximum this little machine is capable of running. I think the little Honda and Predator 2000 watt inverter genny’s will be a perfect match for this thing. So I do foresee a new Predator 2000 watt genny in my future!!.

Run time was almost exactly 1 hour, and it did get hot running this 212 Predator. I think a little 2000 watt inverter generator would probably get over 2 hours or right around this. The jet / nozzle system worked great and did what it was intended to do.

I will be out there as soon as it gets dark to see what this flare looks like.

Thank you. I really enjoyed those video’s.

I wonder if it is possible to develop a set of drop in parts/fittings to convert a more ubiquitous metal container into a charcoal gasifier?

60mm ammo cans are hard to find. Especially outside CONUS.

A drop in kit of no-weld parts to convert paint buckets?

Just thinkin.

Use these videos as just reference and just build it. There are no rules here to follow. Find what you can make work and build it. But try to find stuff with thicker metals. These ammo boxes are pretty limited as they are very thin metal.