i usually blame poltergeist ))

Stripped screws!!! ![]()

![]()

I think we all know what I’m talking about. You know those straight slot screws where the slot has been damaged by a flat tipped screwdriver that doesn’t quite fit. Well, I think I have a solution.

Some years ago I was building a machine and I wanted to countersink some very large screws as part of the drive mechanism. They needed to be tight, so I wanted to put them in with my impact wrench. I made a screwdriver tip for my impact wrench, and it worked so well I couldn’t believe it.

Since then I have modified the tips of many flat tipped screwdrivers with almost perfect results.

Rindert

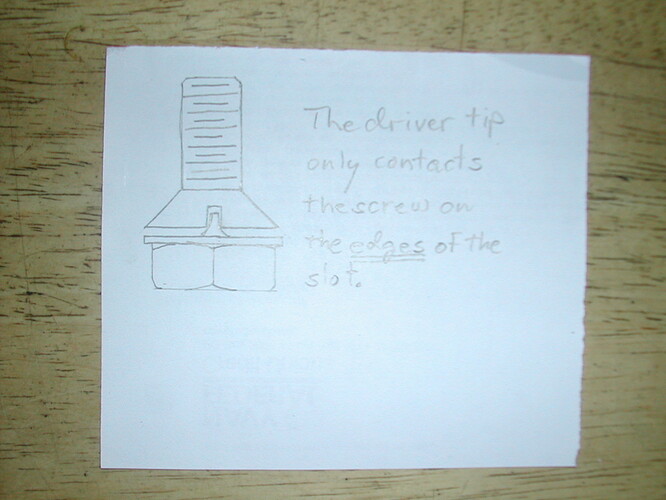

Diagram showing how the tip fits in the slot. The driver tip only contacts the screw on the edges of the slot.

The first tip I made, with the machine in the background.

A tip modified with a file.

This is a very old screwdriver I found at a thrift store. The tip has been ‘sharpened’ to fit a specific size of screw. Years ago professionally trained tradesmen used to sharpen their screwdrivers. Nowadays you almost cannot have such a screwdriver in your toolbox just because of the amount of ridicule others will give you.

I have sharpened them before then hit them with a hammer before turning. Usually high torque applications use a different head like a philips, hex or even robertson. I think all the screws on my 3d printer are hex and require an allen wrench.

Yes, I have seen that too. I have a chipper shredder vacuum from the late 1970s where the chipper blades are held on with countersunk screws. They require an allen wrench.

I think I’ll use slotted screws next time after I sharpen the blades. I rounded off an allen wrench so I had to grind off the rounded off part, and all the screws were a little damaged. Thinking it will be easy to make another driver tip for those specific screws. Then it will be easy to just use my impact wrench to put them in. I know they won’t get damaged.

Rindert

The last time happened, I drilled off the heads, took the part off, and used vice grips to get the rest of the bolt out. The nice part is the rounded out hex slot is perfectly centered for a drill. If you can drill straight, you probably could use an ez out. or flatten the sides for a wrench or slot it with a dremel and use a sharpened screwdriver.

Good luck turning a rusted 3/8" screw with a screwdriver, even if it is sharpened. I suppose you could put a wrench on the screwdriver’s shank, if its square, and maybe get somewhere that way. My point is that with a screwdriver tip like the one I made and an impact wrench its no problem. I think we need some sort of a tool similar to the one I made.

Rindert

Here is what helps. And RindertW. did without maybe realizing?

Frozen stuck metals clamping fasteners you need to impact punch down at their shaft shank. A round flat nosed punch tool no bigger that the actual shaft core diameter. NOT the fasteners outside threaded diameter! Smack repeatedly, hard!

What you will be doing is stretching the fastener head relieving some of the stretched clamping pressure. You are also shock loosening fastener threads “welding” or rusted to the base hole threads.

Then with any re-formed slot or left-handed bit drilling they will spin out.

Yep. A fastener destructive technique.

If the fastener is the rare; and the prize; then cut&chip away the base it is in.

Rusted exhaust nuts come off so much easier if you can rattle them with an air impact punch. And always, always; wire brush the exposed stud threads before turning off! The prize there being the stud and the exhaust casting.

Steve Unruh

Err, I came up with this driver tip just so that I could assemble that mechanism. I countersunk the screw heads because they would have interfered with it’s function. I think that if mechanical designers out there, had the freedom to design this way they would do so.

Rindert

Have any of you used the Racor water/fuel separator funnels? I am trying to clean up some recovered gasoline. So far I have been using settling and decanting through a 10 micron fuel filter.

Anybody know of any floculation agents for gasoline?

I haven’t tried the centrifuge yet. I am not sure it would work. I suppose if it did it would work better than centrifuging oil.

Anybody? Thoughts?

Never heard of that before. I looked up the company. A really wide range of products and prices. All of them out of my range.

ethanol will loosely bond with water, then settle at the bottom. You could mix e85 in it then let it settle out or the water will settle out by itself. then you have to syphon off the gas. This is a pretty good video on what happens.

Given you live by water, I would probably opt for the racor, but it depends on how much water you are trying to get out.

The racor water filter looks like it works to separate, but it only hold so much water. It looks like a really neat product to be honest.

Hey BruceJ.

I am assuming you are salvaging gasoline out of old metal tanks and cans, yes.

So for sure painter cones rough filtering first to get out particles and gel stringers first, yes.

Unfortunately aged, changed, and with components filtered out: under compression pressure the burning characteristics will be changed too.

I’ve only two engines here that will run on old gasoline. The 94 Ford F150 5.0L EFI. Runs, but low on power, without any snap throttle.

And the woodsplitter with the 10.5 hp B&S I/C OHV engine. Bit cranky to pull start. Runs. Bit low on power; and a somewhat HC’s stinky exhaust. It burbles on the edge of misfiring.

I dare not put into any of the tinny, tiny orfice carbureted, high speed inverter electrical generators.

Only the older 3600 B&S scream’o-matic generator. Yep. A reason I acquired that one.

Watts is good watts so long as they keep the lights on. The refrigerators; refrigerating, and freezing. The batteries charging.

So . . . for reclaimed gasoline I think it can never truly be restored for all engines.

Only selected engines usage.

Hey! Half glass full.

Regards

It looks a lot like the surfactant I use for spraying.

Thanks everyone for your input.

I am reminded that gasoline is nonpolar, and flocculation won’t work. I have gasoline that’s mixed with used motor oil and I wanted to flocculate the soot, and filter it with bigger filters. The reason I was thinking about that was because the biodiesel reaction is polar and soot does flocculate in that reactor.

I was told that most gasoline now starts with an 80 isoctane base. So if I wash out the ethanol. I would have a low octane gasoline to work with. Which is fine for the tractors, and generators. I really don’t care about power loss, or any efficiency. I’m more worried about where in the hell to store all this gas. It’s a fun problem to have.

I do mix the gasoline, with the weakest snoose, with diesel/biodiesel and burn it in the Volvo/Caterpillar/Yanmar diesels, and the Perfection pot space heater.

I went ahead and ordered the Racor funnel filter. If I get time I may get around to setting up my centrifuge.

As a side note, now that it’s in the teens, I am not in the least worried about picking up water when decanting…it’s rock solid now.

Apparently there are small distillation units out there. I searched on youtube: separate gas from diesel

Rindert

I think you have multiple issues, and you probably need to address them individually. You know more about this then I do. but this guy made a centrifuge out of an old juicer, which gets out the dirt out… Then he goes back and mixes it with a portion of gasoline to give it some lighter weight alkanes, which means you may not have to separate the diesel from the gas. You just need to clean it.

,

wait, this one just popped up on my youtube algo, and I think it is a lot closer to what you want. It is cheap and you most likely have almost everything you need. And you really want to read some of the comments, like you should absolutely have a condenser before the vacuum pump because there are some volatiles you don’t want in the pump.

Thank you for your thoughts on the subject. I don’t have water in the gasoline. Some of it is just old. Some barrels are a mix of gasoline and used motor oil.

I only use the clean old gas for engine use. I don’t think it’s worth it to use “black diesel” unless one believes the body won’t outlast the injector pump.

I want to use the gasoline/motor oil mix in the oil stove. The issue is the soot will fall out while the mixture waits to be burned. It sort of builds up in the float chamber.

I have a sealed centrifuge for Pennsylvania Biodiesel Supply that would probably work for soot removal. I just don’t have time yet to hook it up.

I have to spend time setting up a holding tank and a 12v pump so I can disperse it conveniently. For now, I can just decant and burn the clean gasoline. I can work on the dirty stuff next summer.

You might look at a Babington atomizer. They aren’t very picky about fuel and are fairly efficient.

Before winter started I made sure my snow blower, log splitter and generators were all serviced and running well. The log splitter and snow blower had old gas in them but it was treated with Ethanol Shield and Stabil and they ran fine so I just filled the tanks with new. Of course the snow blower had to screw up and started surging and only running on half choke. Been there many times before so I know the routine but we have been in the teens fahrenheit and I have no heated place to work on it so I mixed 4 oz of Mechanic in a Bottle and 4 oz of Seafoam in a gallon of gas and ran the snowblower for about half an hour to see if that would clear the jets. Not yet. I’m hoping that sitting with the mixture in it for 12 hours will cure the issue. Never tried the Mechanic in a Bottle before so I thought it would be interesting to report whether is was worth using or not.