Hi Tom .

I’m not sure I understand correctly, do you mean that the pipes (boron blasting nozzle) are simply held in place by tightening?

I have only used the hexaloy tubes but the boron ones are the same idea. I have welded the pipe nipple to the wall of the fire tube. The nozzle is just slides into the steel nipple and is held in place by friction.

I also got some that had a 3/4 NPT that will screw into threaded pipe from Bruce Southerland and that also held up very well , he found them on Ebay i think but if he reads this i am sure he will let us all know

With those Boron nozzles i just got a slight under plug fit and then heated to expand the tube to slide over the nozzle and just to make sure added a little furnace cement around just to stop any air leaks seemed to work a treat .

Here are 4 photo’s of the Boron nozzle that help up very well you can see what it looked like after i cleaned off the slag the ends are in perfect condition , the other 3 photo’s are of the nozzle that Bruce sent me this is 1 of 3 that i have not used yet as one is still in a downdraft charcoal gasifier .over 5 years now .

Dave

Impressive, Dave. I think you’ve already mentioned this. I’d forgotten about those boron nozzles. Are they fragile and sensitive to impacts?

They seem to hold up well to the knock and bangs i gave them , but i wouldn’t go hitting them with a hammer just in case , that first one i had to clean the slag off it and that was basically molten glass i think i was chipping away at him with a small hammer and a grinder to get it off and that’s after about 60 hours of heating and cooling cycles ,

I also have a piece of Tungsten Carbide that was totally untouched after running as a nozzle for a while , trouble is that’s not cheap even as scrap , plus i got stopped at every security desk at airports as it shows up as solid black on the X rays unable to be scanned and they all wanted to see what the object was .

Dave

Hi All

Here is a tool I’ve recommended feedback:

My first NOCO Genius 1 failure.

I have six of these now. I cut it open to see if it was a design or manufacturing failure . . . Or a ME failure. Picture does not quite show the water droplets inside even after days drying by the wood stove.

Water inside, so it was a ME dumb-shit.

It’s lived months under maintaining charging the Hyundai battery. Normally living dry stretched over into the back of the GMC box van. It sat out on the hood edge in our rains. I forgot to stretch it over plugged in under cover.

Sheez. So I pulled some equipments batteries and lined up positives and negatives and will daily move and charge until I can get another new Genius 1 next month.

All-in-all using Aspen fuels as storage, and these 1 amp maintainer chargers has made my life turn-key, and one-two pulls starting confident.

Ha! Except now the pictured wood splitter! The cam mounted compression release is getting obviously worn. Only ~15+ years old. Sometimes it will kick pulling back hard. Damn that hurts.

Courage and determination SteveU.

Only 4-5 months more to use. And then in May/June fair weather, I can open it up and repair.

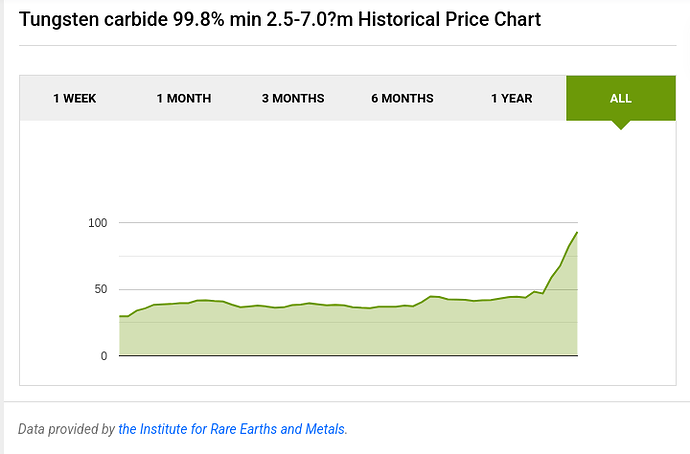

Apparently you will need to order them from the US, the Chinese market doubled around July which is about when Trump put his tariffs in. I don’t think demand created a 100% jump in price for carbide over 6 months. This is FOB from China.

May not help, but when we bought a former-rental BCS walk-behind tractor a few years back, it had a Honda GX390, with LOTS of hours. Smoked a little on start-up if it had been sitting, but ran okay. And it was cheap ![]() I didn’t have to worry about putting the first scratch on it either.

I didn’t have to worry about putting the first scratch on it either.

But it did like to pull the starter handle through my fingers, which is not what I needed. I figured I’d deal with it later, since I didn’t like the idea of splitting the crankcase and replacing the compression release. But I wondered . . . it works by floating the intake valve when it’s turning slowly. How far open does it hold that valve? I pulled the valve cover, and checked the valve lash, which was well over spec. I reset the gap, put the cover back on, and no more kick-back. It’s run for, I think, three years now, mainly powering the splitter. Still smokes off and on, but no more sore fingers. At least, not from from that engine ![]()

Might be worth a try.

#1 reason why I like to buy used equipment. Price is #2 and might be tied, but not worrying about the first scratch or an out of warranty modification or future resale value, isn’t worth it. I’d rather let someone else do that.