@Jeff took the approach of having an upper hopper feeding into the depression of the reaction zone. I like that idea.

The real saving grace of Kristijans nozzle is that because its vertical facing holes are getting a good protection from slag build up around the holes that in turn help to keep the nozzle intact , if you then replace it with a horizontal nozzle i think that it will start to oxidize away because of no protection from a build up around it and the amount of hight gained is next to nothing compared to the vertical holes .

Looking at your drum in the video shows that the hight of where you have the nozzle mounted could come right down at least 4 inches maybe even more , just place a layer of high temp ceramic blanket on the bottom of the drum covered in some ash and you should not have a over heating problem below the nozzle then ,and you will gain plenty of extra hight .

But i want this to work not only for you but for all of us so i am keeping my fingers crossed in the hope that a thick walled plate will work as the Pedrick system does , as far as the heat migrating up through the charcoal ,i think its what we have all come up against at one time or another and thats why a taller and smaller diameter drum works better than a larger dia that isn’t as high .

Dave

I hear my name mentioned so l shuld probably chime in

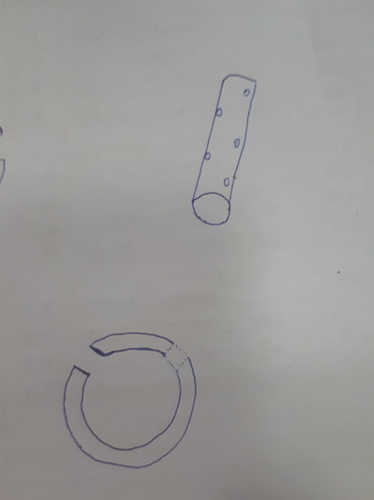

This is how l imagine the flute nozzle principle. You guys mentioned most of them.

- nozzles facing up are protected from direct contact with white hot coals via charcoal and ash/slag

- there is a small surface area where the metal touches the heat (nozzle tip) and a vast surface where the heat can be dumped and put to good use preheating air. Thats exactly how a WK firetube works. Mass is critical here, becouse you need mass to conduct the heat from nozzle tip trugh the whole pipe. So is pipe diameter becouse with a bigger diameter pipe you get more surface area for the air to cool it.

I designed it becouse l had the same problem as you Steve. I was wery height limited so l thod “l cant go up, but l can go sideways”. This is why l made a short and wide gasifier, and many nozzles on the pipe. The idea was to make not one big tall reaction zone, but manny short ones.

Now since you have a round gasifier, you are limited for width/number of nozzles. But perhaps you culd try something like this?

Not having the holes on the top but offset say 30° from the vertical in each direction. Shuld still work without burning up the nozzle yet make a lower reaction zone. Not trying to push you or anything, just speaking my mind here.

Be sure to report how the heavy plate works!

Thanks to all of you for your input. I couldn’t do this project without your help.

Gary, thanks for directing me to Jeff’s Pederick style fire plate nozzle. I found a photo of it. Two drops a second is the rate I aim for with the water, but that is continuous, since my control is out of reach. Yes—experimenting—there seems to be no end to it. Reminds me of the comment of some rich guy, when he was asked, “How much is enough?” He replied, “Just a little bit more.”

Garry T., Jeff’s hopper arrangement makes good sense, but due to my limited fabrication skills, I really need to keep it simple. A small reactor underneath the barrel would be good, but adds to the complexity. I have wondered about modifying the barrel lid some way to allow for some extra volume.

Dave & Brian, I’m also sure the slag protection is part of it. I removed a couple of large chunks when I dug out the nozzle, but I’m hoping metal mass will enable this one to survive. I think the typical side entry nozzle needs more space under it. Since that is what I was planning for originally, I located it about 4.5 inches from the bottom of the barrel. Using the floor flange to connect the plumbing to the barrel also limits how far I can go down. The floor flange would probably fit at the most 2 inches lower. But it is where it is and I’m trying to figure out how to live with it. The 16 gallon drum is the only size which has good proportions for a charcoal gasifier, but is not big enough for a vehicle. Trying to work with what I already have with minor modifications and get where I want to go is a challenge.

Kristijan, I really like your nozzle design and may very well go back to it after trying some other ideas. I know the real problem is that my reactor is not tall enough for a vertical nozzle unless it is mounted near the bottom or perhaps mounted on the bottom, like Gary Gilmore’s original Ranger reactor. I had wondered about the offset hole idea you mentioned. I will have to put that on my list of things to try. Thanks for the suggestion.

I have driven about 15 miles plus maybe an hour of idle time for testing purposes on the new nozzle. It appeared to be running rather hot on the air inlet side of the barrel, so I decided to dig it out and put on a longer pipe nipple to move the reaction zone toward the center of the barrel before further testing. Look at what I dug out . . . .

I’m sure from earlier comments that most of you are not surprised. Needless to say, there was no need of reinstalling it for further testing. So, it is back to the tried and true—the Lettinger nozzle. I decided that the next path of least resistance is to lower the nozzle as much as I can while still using the floor flanges. This will put the nozzle pipe about 1.5 inches from the bottom of the barrel. Here is the beginning stage . . .

The plan is to prepare two sheet metal plates—one to go inside the barrel and one for the outside, covering the original air inlet hole, fastened with bolts, sealed with RTV gasket material and sandwiched between the two floor flanges. I think it should be sturdy enough and I hope will seal up well. That should give me at least 7 more miles of distance and guarantee that I’ll be able to go most places I go and return home without having to stop to refill.

I’m noticing a problem with the way the engine runs which some of you might be able to advise me about. When I’m sitting in the driveway with the car in drive, my foot on the brake and begin to give it some chargas, the engine will speed up to a certain point and then sounds to me like it starts miss-firing and the power drops off until the load is reduced. I’m planning to try several things in this sequence–new plugs, reduced spark plug gap, perhaps a new coil. I was wondering, what are the symptoms of too much back pressure or resistance in gas flow from the gasifier/filter system? Could that be what I am experiencing? I think I checked that out once, but may try again after the ignition tests and observe the results more carefully. In normal driving, I am often experiencing very low power start ups in first gear and some fluctuation in power when running in third (the highest) gear, kind of an irregular pulsating feeling. Perhaps some of this is due to fluctuations in gas quality. Maintaining high rpms seems to help, but does not completely avoid this problem. If you have any thought, please pass them on.

Don’t forget about the rotor and distributor cap. I just finished chasing my tail for a similar problem. TomC

Hmm, i am guessing that the burned out part of the flange was facing towards the top of the hopper? You should maybe post your results in the Nozzles thread, because I feel like this illustrates the value of a vertical nozzle. I suspect that the reason the Leitinger nozzle is working so well, is that it creates a nice shelf for the slag to build up on around the nozzle, and it is also pulling cooling air through the hottest spot. I suspect that adding more mass to the flange would not have changed the outcome (perhaps delayed it?). Slag formation does seem to cause problems if it is allowed to build up too high - so I cant help but wonder if some unique geometry exists that nobody has tried yet. I have given some thought to the idea of a nozzle that was angled down towards a grate, some sort of a mix of a Kalle and a crossdraft… Anyhow, keep up the good work, I am looking forward to seeing your latest design.

Steve,

I’m not running plain char, but…

I usually find the air setting very picky and stalling at idle is very likely when the system is constipated.

Running a very rich mix, on the other hand, gives exactly the symptomes you described at first: Idle is ok, but any throttling makes for miss-firing.

Tom, in the last year I have replaced the rotor, distributor cap, wires and plugs as well as the igniter. Except for plugs, and igniter, I think everything else was OK. I was just changing them due to the possible age of the components. It was only after replacing the igniter that I noticed the miss-firing problem. I may have not been paying as close attention to it before, I can’t say for sure.

Carl, yes, the burned out part was facing up. Perhaps the cross-draft design which typically has a side entry nozzle, functions like the vertical nozzle in an updraft design since the gas exit in both cases is opposite the air inlet. and not at right angles to it. I’ve learned my lesson.

JO, I will keep your thoughts in mind when I start running a series of tests next week in an effort to figure this out. Thanks.

I have all the pieces to put the gasifier back together now. It will be a hot job. We are expecting mid-90’s here all next week. I’m looking forward to lots of quality feedback from the ARGOS event. Safe travels to those of you attending!

What do you mean by “igniter”? TomC What do you have for gas atomizing, carburetor, fuel injection, etc???

Tom, Toyota calls this an igniter–probably what is usually referred to as an ignition module. As I understand it this part takes an impulse from the Signal Generator and acts sort of like a relay which sends 12 volts to the ignition coil when it is time for a spark. The igniter along with the Signal Generator replaces the points of years past. This car has a carburetor.

Sounds like you have pretty well covered all the electrical components. Sorry but that is about all I have. A far out thought that I have is you might have a vacuum leak. That is a tough subject to desifer. One method is to take a small propane torch and open the valve but DON’T light it. Then go poking the tip around the intake manifold, carburetor and an air leak will show up by an increase in speed of the engine. ( Oh, I forgot to say have the engine running during this test.)

Do you have the old igniter that you could put back in to confirm whether the miss-fireing occurred before changing igniters?

I down to wishing you good luck. TomC

Tom, The old igniter was replaced last fall after checking everything else because I had no spark situation. I wonder if I bought a bad part or if there is another weakness in the system. Today, I put the gasifier back together with the nozzle lowered in the barrel. I’ll start testing Monday, Lord willing.

Here is an update. I think I’m about finished with this project (stop laughing!). Had the best ride yet today—25 plus miles on one charge of charcoal with good power starting up from stop lights, stop signs and climbing hills. About 2.6 miles per pound of charcoal. According to the car specifications that gives me a charcoal to gasoline equivalency of less than 10 pounds to one gallon. I used about 2 drips a second of water and a little exhaust gas.

I finished reinstalling the Lettinger nozzle in the lowered position on Saturday and expected to spend this morning troubleshooting the miss-firing problem mentioned earlier. The first thing to try was new spark plugs. I am very pleased to report that the new spark plugs solved the problem. Although the old plugs (maybe a year old) looked good, someone suggested that heat might have caused them to deteriorate and suggested that I try new ones. With that problem solved, I decided to take it for a spin. That was going so well I decided to see how far I could go with the lowered nozzle. I probably could have gone further, but I was satisfied with the distance. and pleased that the reactor lid temp was only 250 degrees F at the end of the run. Lately it would be at 350 after only 12 miles. So that was a considerable improvement. The filters did a great job, too. Here are some photos. Come by and we’ll go for a ride.

Really nice looking installation. With my bad memory, I will have to go back at all 134 posts to get the entire picture in my mind. I will make one suggestion (as if I haven’t made enough already) is there any reason you are keeping the trunk lid on the car? Looking at the side view of the car, it is causing alot of air drag. With it off your gasofier would be about even with the poof line. TomC

Tom, Yes, I know what you are saying about the trunk lid. I’d get more cooling of the gasifier, too, which would also be a plus. My thought has been that it looks a bit more normal or what some have called “stealth”—at least from the front. Also, my intent was to avoid altering the original car. It would be a simple matter to remove it. I would just need to find another location for my water drip tank. A water-resistant metal tank mounted to the side of the reactor would work. I’ll give it some thought and may try it. Thanks for your interest.

Tom, I have thought that the wood gas cars I’ve seen look odd with the trunk area open and no lid. But I’m sure a car with a gasifier on the back looks odd, too—but a nice kind of odd. You are right, it makes good sense from a practical standpoint to remove the lid. Who knows, if I try it, I might like it. We’ll see. Thanks again.

My not so humble opinion: Forget the stealth, if you’ve got it, flaunt it. The more gawks, the better. Great conversation starter.

I was totally in that camp as well, not anymore.

It was really fun… Until my insurance company canceled my policy…

Be careful,

Mine was cancelled out right no negotiations.

The only company that would insure the truck wanted $4000 a year to cover it.

I parked the truck in 2014

I vote for stealth and a careful approach to anyone ya don’t know well.

Tom and Bruce, what do you think of this?

Terry, This is obviously not a bunch of barrels sitting in the back of a truck. Perhaps I should be more concerned. It might help that this vehicle only will be used to demonstrate charcoal gasification and to give the occasional ride—unless disaster strikes, that is. So, in a sense, it won’t be very visible. I do get questions from bystanders, like, “Did this pass inspection?” and “Have the police ever stopped you?” A gasifier on a trailer might be a better arrangement if it becomes an issue. Then it would simply be a stock vehicle (unless the trailer is attached).