Good evening Chris saenz, nice project,interesting. hope it works good when done, I gess it will help a lot.Thanks for tackeling the add on project.

Would it be possible to repurpose the old cruise control vacuum modules for this?

Hi, Matt!

Basically a diaphragm with one side open to the air and the other one closed and connected to some other ”vessel” will do some job based on a pressure difference to the atmosphere…

Active diaphragm area times the pressure difference gives the power…

If jou are going to ”destroy” the speed controller you have a good ”bellow” to set the cranking vacuum against a suitably strong spiral.

Max

Yeah that is what I was thinking they are already made and probably could be found in the junk yards. If these older ones all gone then maybe a brake booster could be modified. Might save some time and effort

Brake boosters are big and cumbersome. A diameter of 3" might be big enough to handle the flap mechanisms; it depends on the vacuum you can crank and how much you are satisfied with.

Setting the “let in” vacuum at about half of what the cranking can reach maximally with EVERY route closed seems to cover all situations reasonably?

Crankcase ventilation has to be stopped under ANY of the flaps, including the gasoline-air route. Crankcase ventilation has to be set abowe any flap!

Max

Then there are bellow hoses that can be adopted and put loosely in a protecting tube…

Max

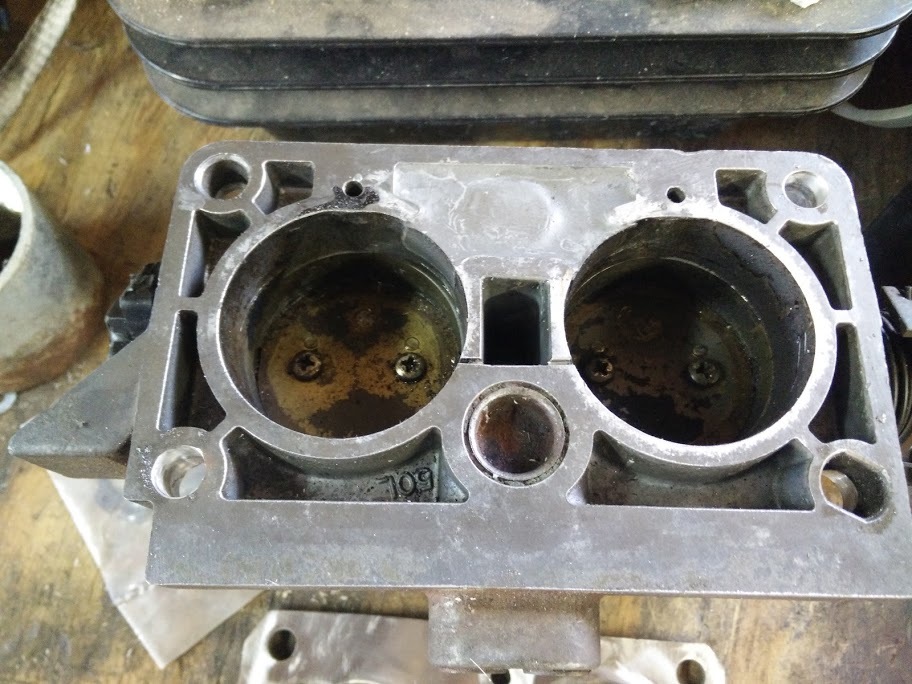

Progress report. Today I’ve been working on the “twin flaps” aka the woodgas throttle. They must be distinct yet identical passages, one for air, one for gas. I’m using a Ford throttle body from a 90’s F-series truck:

First I plugged off the idle passageways. JB Weld in the center area:

A rivet, to close up a hole in the throttle plate:

Now for the output side. Max says it needs to swirl some so it mixes together, so I’ve made some deflectors to get it spinning:

Then I need to merge the gas and air:

And then a fitting for 3" PVC, something I can clamp a Fernco on to:

I have tested the airflow with a shopvac, there is lots of swirling happening. It will spin a pencil around pretty quick. I may at some point add an inline swirler, but I’m going to start with it as-is, I think it’ll work fine.

I see the first picture Chris but the rest show as round circles with a horizontal slot in the center. Are these supposed to be that way?

All fixed, thanks Don.

“No: 7” is still missing…

Hope the “scoops” are identical and not restrictve. Looking impressive!

Max

That’s impressive. Your too young to remember the vacuum cleaner, beach ball demos in the dept. stores, but it’s all good.

Assembled the pieces to test it out on the truck. It took a few tries, and I had to diagnose a massive leak from a pipe breakage. Other than that it worked great! Automixer does it’s job beautifully.

Sorry for the long video, I did try to edit it down. Truck starts at 5:35.

Well done!!!

Excellent!!!

Very happy to see you’re progress!!!

Hey Chris,

That is way too cool !!!

Well done…

My hat is off to you, young sir! Truly beautiful work. I can’t imagine where that unit is going to fit under the hood though.

Front right corner, lots of room in there.

I’m super impressed Chris!