Thanks, Jim. I have not seen those before. I wonder how long that old gas-bag of a car would run. Its a great example for all those who ask about practical storage of wood-gas for vehicles. The “filling station” was also interesting. Yes, those log chunks were mighty big. Remember, this was likely newsreel footage and a bit staged, like the junk-mail and dead-cat scenarios. Notice how few other vehicles on the road. Thanks, and Happy New Year to you!!

Could it be around 10-12 cubic meters in volume?

If we guess the car use around 20hp at cruise and use 40 cubic meter of gas an hour.

Then he would have a run time of ~17min at 65kph/40mph he would get 18.5km or 11.5 miles.

You probably right on the refueling is a bit staged.

The same in the wood powered car video where they also use big irregular pieces.

Looks much better when people don’t see all the extra work going in the preparation.

Minimize preparation is a big goal! Atleast for me.

Wish you all a happy new year!

This footage was from the netherlands. The gasifier was a retort system and the balloon was filled with pure coal gas. ( 100% CO for reference ) That mixture rate was about 2,4 cbm air for 1 cbm of gas. Engine slightly running over 2000 Rpm with 1,8 liters engine size.

Balloon was about 8 cbm of gas. Runtime between 30 and 60 minutes before refill

The roadster was a Peugot 401 or 402, the second one is a citroen traction avant , i think model 11BN

Correction. The roadster was a '34 Ford TomC

Thanks for the information!

So the roadster did run on retort gas?

I have never heard about a car runing on retort gas, I have so many questions!

Retort gas is very dirty?

How would they clean the gas?

How do they regulate the retort so doesn’t “run away”?

Do you have some more info on the retort “gasifier” or know where I can read some more about it?

Seems like a fun way for making charcoal!

Yup, seems you’r right, i stand corrected…

The gasifier was a " Maus Gatsonides gasgenerator"

I am searching more details

Yes Koen, you are thinking the same as I. We need to know more about this retort gasifier I notice the off set fire tube on this unit and how the light up was done by the clean out ash pan. I wonder if this gasifier acts like our more modern fire places stove of today but in a down draft mode. It must of had some kind of grate above the ash pan clean out, by the way he was lighting it up. In my search in the library on DOW I did not come across this design. Granted I have not search the complete library. Thanks for the name of the gasifier unit. I remember @Wayne in his earlier gasifier units putting in big pieces of partly charred wood. Maybe he has seen this gasifier design.

Bob

Nice find, Bob!! Thanks to Koen for knowing the associated names!! Happy new year!

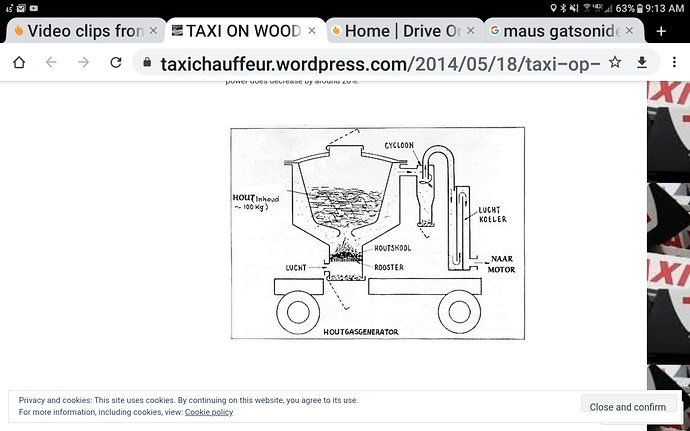

This link contains a sketch from the design gasifier with the roadster

and some nice pics

Thanks Koen, I took a snap shot of the diagram and posted it here. Great pictures, and pictures I have never seen before. Wow! A WWll tank gasified. So Gasification on my motor home is possible, but not too practical. Also the pictures of people clean out the gasifiers and changing the filter material. Yup the women did it too. Thank you.

Bob

Thanks for the the digging!

But I can’t understand how the diagram labeled houtgasgenerator, would work.

The coal fire would pull straight to the cyclone and only feed co2 and air to the engine.

And would not the gas that would be made in the hopper have a lot of tar in it?

The extra air from the fire would also burn the retort gas?

Hi Jim, the simple diagram does not show how it would really look when running on wood. The lighting port is where the air comes in under the grate and goes through the charcoal bed of coals. The whole area above the grate is filled up to the hopper bottom opening with charcoal and fire. It is more than likely that there is a greater distance between the hopper bottom opening to the grate 15" or so. Just by looking at the pictures we have of the gasifier mounted to the car and measuring the pictures. The grate is going to fail unless it can be protected from to high heat of live charcoal touching the grate. The use of cold air is used to help protect it in a up draft movement pulling the heat away from the metal grate. The hopper is a sealed unit with I hope a relief pressure lid to open and refill with wood and case of a gasifier burp or back fire. You might notice the flareing of the bottom of the hopper to concentrate heat up and into the wood of the hopper. With the retort action of heat on the sides of the hopper and moisture coming out of the wood and going through the fire and charcoal and up into the gasifier reserve gas area, soot drop zone area and into the cyclone filter I see a problem here… tar and lots of moisture to deal with. May be in the completed blue print design they dealt with that and it is not shown here but a very simple drawing design. Hiding the secrets of how it really worked. But in my opinion I would not hook this unit up to my engine as it stands. It is a lot better design then that of the FEMA gasifier design for sure.

Bob

Okay, so if I get this right the system is more of a gasifier and not a retort system?

And it works like a updraft coal gasifier with a charcoal maker on the top?

As long the hopper is capable to make enough coal, it would probably work quite well then…

Looks like a simple construction, like a simplefire with a hopper on the inside, maybe something like this drawing would work?

Hi Jim, right at the spot where the air touches the charcoal coal in you drawing the temperature is going to get up to 2000 *f . The metal bottom and nozzle will melt into a puddle, I know this because I have done on my Charcoalgasifer with a similar design, mild steel can not handle the heat. You have to be able to pull the heat away from the steel and keep the white hot charcoal from touching the mild steel. I have used ceramic wool and stainless steel in the white hot area with some success. I am still working on it with my Charcoal Cross Draft gasifier. It is not of this design that we are talking about here. I need to change my hopper feed to a direct vertical feed to right above the nozzle to make it work correctly. May this spring I will work on it some more.

Also the ash will plug up all around the nozzle and slag will form. You have to have a place for the ash to go to be cleaned out.

Bob

Yeah I know it was just a fast sketch, the intake could look more like the Gatsonides design with a grate of stainless.

But do you think the principle is correct?

Koen, Wow, what a treasure-trove of photos!

(late Middle English: from Anglo-Norman French tresor trové , literally ‘found treasure’.)

The principle is not very good because you can get tar into your wood gas stream going to the slycone filter this will plug up the filter and damage your engine. The Idea of good Gasification is to not let tar get to the filter and also as little moisture as possible.

I am looking the drawing over and if there is a way to collect the hot moisture and tar gases and cool them down to a liquid. Store in a condensation tank, and keep the hopper circulating the gases to remove more, just like a WK hopper does. Then this gasifier design might work. Putting in preheated hot air might be A problem, you will lose the cold air protection. A WK hopper is a type of retort with heat Only from the bottom radiating up into the wood. Turning it into brands and not completely to charcoal. Leaving some moisture H2O in the wood to convert to H2 Hydrogen.

One other problem is the turn down ratio is very low in this design. This would have to be addressed for idling the engine and low speeds driving if used in a vehicle.

Here is the Big Question: Why was this gasifier not put into mass production, I found only one car so far. RED flag waving here. Why waste time on a gasifier that will make tar and let it go to the engine and ruin it.

It might work as a Charcoalgasifer, the tar has been all ready removed.

If you build a WK wood gasifier or the Imbert Gasifier I know that they will work. Stick with the proven gasifiers builds learn to run it.

I will continue to look at this design because it is so simple to build.

Bob