Hey guys. Here’s couple of differently-done make-your-own electricity DIY projects. In the past 50 years I’ve made up quite a few small engine/auto alternator systems.

But never actually using the whole lawnmowers bases as these two fellows did.

The reason to use a small engine instead of just the whole car up on wheel blocks is for fuel use economy.

From the first fellow learn that using the whole push mower deck and all saved himself a lot fabrication. And he then had wheels portability. Learn from him that you CAN make up a useable V-belt driven pulley by welding or brass brazing it to the existing wrong-for-you shaft sprocket/multi-groove pulley.

From the riding lawn mower guy learn that he DID make this allowing his rider lawn mower to still be a lawn mower. And he did set up his system to do just as I say I will longer term fall back onto. Downed vehicles multiple 12vdc lead acid batteries. Same. Banked up.

From both, watch carefully for just what you’d need to have ahead of time in an all-fall-down to make up useable systems for others. INVERTERS. Meters. Cabling ends.

Could be your values barterable skill. Become your areas Generator-Man. They can’t all come live with you!

One of two kept stored front axles and decks worn out old rider lawn mowers I keep as somedays. 17.5 hp electric start, pressure oiled/w oil filter, Kohlers singles. 490cc. Woodgasable.

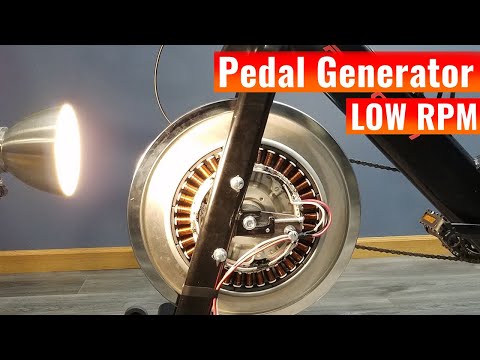

The alternator is modern ~70% efficient 120 amp one from our Hyundai Tuscan. Picture hardly shows the two extra turn on-off external and voltage sensing terminal versus the old 1970’s 40% efficient one-wire alternator that he used. Get used aftermarket manuals with diagrams ahead for your own vehicles. Know those extra alternators terminals. Use them.

Hole saw out the center of one of the mower deck pulleys and weld or braze it on to that Mando’s small micro-groove pulleys front rim.

Get your pulleys set-up for best of an engine’s slower 2400-2800 RPM; and driven alternators best power curve and internal fans cooling min of 4000-5000 RPM to really save on the noise, wears, and fuels used.

Sure. I seen guy systems, they actually did step by step build up for whole house integrated PV; Generators; and even woodgas. $15,000-$30,000 spent out. Wonderful. Power out long term how many others do you want to take in, eh. Set them up, after the need, with something to keep them at-home. Using their own stuff, mostly. Just being neighborly.

Hey. Here is how do something DIY, today. Do this weekend. then Learn-use. Improve later. Or for a J-I-C system, maybe just use it KISS, basic.

Use the Projects Farms guys videos to let him guide you to the bests needed drill bits; hole saws; stepped bit small holes maker. Other seen used tools. A fellow could make these conversions up no-welding. No Lathe. No Milling machine. No plasma table. No 3D printer.

Enjoy these. Imagineer in real life. Not Net-life.

Steve Unruh

![]()