Obviously, that was just the sound of the rod getting ground up and now it’s just a fine powder. ;D

@ Handy_Andy Nice finds Andrew, thanks  Yeah I might do a slight lift on her with those meats. Funding will soon be in and Ill be able to get all the rest of the parts along with new tires and rims. Hopefully before the end of spring.

Yeah I might do a slight lift on her with those meats. Funding will soon be in and Ill be able to get all the rest of the parts along with new tires and rims. Hopefully before the end of spring.

Yeah Brian, Ive heard these little motors make noise like this before. but this was pretty extreme, I have no idea what was causing this. I gave her an oil change today and put her mostly back together minus some guarding. Ill get that stuff back on when I re install the mower deck. I got to put new blades on it and chop out some cancer and graff in some new new metal on it. Then it will all be complete as it was.

So here bellow is the completed one.

The question now is where do it mount the M-1 this time. lol

So here is next weekends project, hopefully it will be warm enough to take her to the pressure washer. Not sure if Im going to have it sand blasted yet, but leaning toward having this done.

So both of these will get gasified, I think I am going to try the new Micro on the current running one and see what happens. I have ran our test unit with it, its a 9.5 horse. So I think it will do it just fine and would be nice and compact on the little tractor

Found some code here that might be useful Matt:

PID loops always cause me grief because they have tricks they play on you.

This one seems to have all the tricks neatly accounted for and it might make a nice addition to your code if you decide to go with it.

Small and simple but I think running too many at once would be a processor hog.

http://brettbeauregard.com/blog/tag/beginners-pid/

Very cool, well when we get to the PID’s I will have this here  at this point it may be some time before tackling this part of our evolution. We have the new Revolution R1’s coming online soon and coding will all be behind the scenes for first gen self running mode. I might just flash leds as warnings if need be. But I will have my work cut out for me on this first round me thinks.

at this point it may be some time before tackling this part of our evolution. We have the new Revolution R1’s coming online soon and coding will all be behind the scenes for first gen self running mode. I might just flash leds as warnings if need be. But I will have my work cut out for me on this first round me thinks.

I just did some load testing on another Flex with Predator and was able to get 6200 watts no problem. The Predator is just an awesome machine, Id put this up against any other brand they are good machines and this is 5th or 6rh one we have built. All have ran out of the box exactly the same, they are hard to beat at just $1700.00 out the door.

And yes Im cooking on woodgas again and running my chain saw haha

Edit: yes I know the gas shut label is showing the gas is on, the stupid label is incorrect. Ill be redoing this video hopefully tomorrow with the line disconnected. So there is one flaw the predator has

Hey Matt, that is pretty awesome; what is the run time on that unit before reloading?

Hi Mat

what is the filter material in the can has ammo?

why did you choose the one?

Do you think I could use it in the filter of a coal gasifier ?

Thierry

On chips depending on density it could run from 1 to 1.5 hours. On pellets it will for 3.5 hours.

Those are lava rocks. I choose this because I needed something that could withstand the temps coming straight out of the gasifier. This machine here is a very simple machine that are offering at very low cost. It can have added filting added on with different filter medias.

For coal dust no, at least not alone. It would make a good pre filter but you will need additional finer filtering methods.

Very nice video MattR.

Kick out if I full screen it for on youtube viewing.

Is this one you want to remain only private viewable?

Best Regards

Steve Unruh

Hey Steve, it should be public. It is for our UK client actually. We are brainstorming on possibly manufacturing this like our larger machine with full integration. The issue with the Predator for them is its two phase I believe. So what we could do is just get the 22 HP Predator engine and couple a Mecc Alte head to it. This will then open up other possibilities to take this to 10 kW output with a two pole head running at 3000 RPMs UK standards.

Steve, try clicking on the you tube logo at the bottom right of the screen right next to the box you click to full screen the video. That brings you to you tube where you can click on full screen. That seems to be necessary on most all DOW video posts.

Ok Im going to do a quick review on the electric chain saws. Since this has been a topic of discussion running a chainsaw off of wood gas an electric will be the most practical method.

I purchased the HF saw and to tell you the truth it “was” a pretty good saw for our needs of chopping up skids. However, if you get this saw get the replacement plan, if you break it you get a brand new one for two years. I did not and I abused that saw pretty bad got her hung up on nails quite a bit and stripped the gears out internally. If used as advertised its really a pretty good saw.

Ok now for a little more dollars you can get the Polan 3.5 hp saw. I have only had this for about week since the HF saw went into the garbage can. For around 30 bucks more this is five times the saw and is a better bargain. I looked at other saws and this one just looks like a better made saw than any others I seen locally in stores. It has tool free operation and seems to work quite well. It has quite a bit of power, might be able to take down some small trees with it even. Its been 15 years since I ran the Husky’s and Stills saws so I cant give a comparison there. But if you are in the market for an electric to run off your wood gas generator system, the Polan I believe is the best you will find for under 100 bucks!!

Ok I have the John Deere back in working order. This is the one, not getting the full restore, just back together so we can use for work. However, the plan is to gasify it again, some may remember this one with one of the original Micros I think we had both a generation 2ish and later a gen three or four. I was thinking of putting the new Micro on this, but was planning on introducing a second larger version. So this is the plan and I guess justifies building the first one.

This will be again a series machine; series I, II and possibly III each growing 2" in diameter and a little larger height wise. The new M-2 will be a 6" diameter machine and will gain about 4" in height over the M-1. The M-1 can run chunked up foliage OK but it is very quick, so one of the reasons I want this larger machine on the tractor. It should run fine on both pellets, and chunked up fuels. It will probably do Ok with hardwood chips too, but will need to test them. The M-2 will get a more traditional filter system and get our standard centrifugal filter like on our Flex machines, a small gas chiller and then an add on ammo box media filter. This will just get coupled via hose attachment and sit on the ground or can be mounted to the application. The gas Chiller height will be customizable as well. The core cooing tubes will be coupled into place via short hose couple with spring clamps.

The John Deere is going to get a 110 amp alternator and a battery with inverter set up on the back. So this will be able to run my Chain saw and many other things, like my cook top. and still be able to mow shop yard.

I have two Micro Series getting ready for weld for Argos. Still not sure if we will even make it. But we are at this time planning to go. So hopefully we will have the tractor and the Micros ready by then. We will have the Prototype up and running the cook top and our BBQ. I did by the way get a new grill I got Char Broil portable gas grill and made a simple mod to adapt the quick connect couple to it. It runs the stock burner no problem its actually prolly a bit much, I throtle the thing back to keep it from melting down. haha.

Couple pictures of the first production Micro Series I gasifier. This one ships out Tuesday.

I managed to get all parts CNC’d and saw cut. Took about 3 hours, how we did this with out a CNC machine is beyond me. My employees don’t know how good they have it. Back in the day when we started we cut all this stuff out with a grinder haha. I would buy out all the air tanks our local Tractor Supply had. They couldn’t keep up with us. We would cut those things apart with a grinder like many of you do, but we were doing this daily lol. That was a dreadfull job, four years into this and looking back seems like an eternity, but that wasn’t really all that long ago. Its amazing how we have evolved!!

Might even stick some metal together tonight, during the week my project have to take the back seat.

Man o man that sure is a pretty flare

Make my heart go pitter pat

Some day, l cam only dream of making has of that quality

Just follow the Imbert specs and you will do fine. Add a mild air preheat and maybe add some to the reduction length. You may need to perform more grate shaking but the reduction is the heart of the system and is where all the magic really happens. What happens above this is the simplifying of the molecule chains so indeed that plays a big part of it. The more simplified these chains become the easier it is for the reduction system to its job of making these reactions happen and more thorough. The driving force is HEAT so insulation, the air preheat methods, using properly sized and dried fuels, a good flow design and other things all are at play. Much of the causes of our failures are flow issues, causing the machine to crash, once tars are made and are not cracked they become embedded in your reduction char, making a mess of things. You then have to burn this all out or completely empty the machine out and start over. This typically causes a flow issues and is hard to recover from unless you have a very strong blower. Alls I can say is build it and have fun!!

Ok I have quite a few updates. First is the grill this is the Charbroil portable gas grill Ive adapted to run on the Micro Series 1 prototype. The pic of the burner is through the lighting port I tried to take a pic from above but nothing showed in the pic. The first pic is after around 15 min or so of running and the later is after 30 min or so with the grate becoming restricted. After a shake you get more orange back in the flame. But this thing is making some great food, I use it almost daily!!

Im getting ready to build the mounts for the John Deere conversion. Not a whole lot to report, Im trying to find time during the week to get this complete. Id like to move on by the weekend and install the turbo charger and adapt the alternator. I got a 55 amp marine alternator in ccw rotation, so it wont have whole lot of charging but will do for what I plan to use it for. Along with this is setting up the inverter in the back.

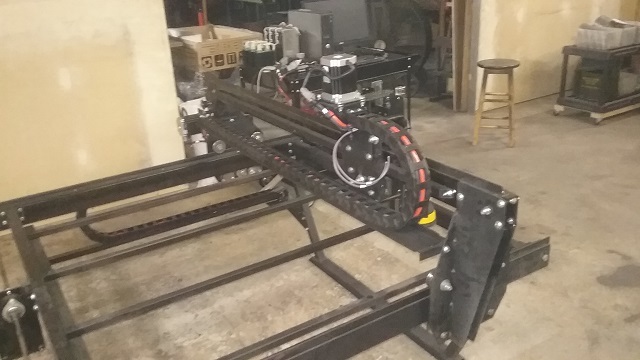

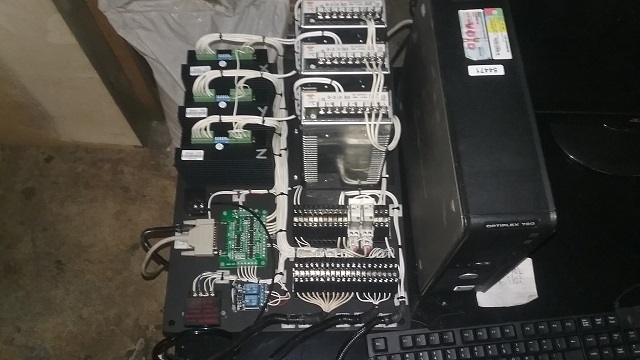

I have been working on the CNC machine, we had an investor/purchaser grant us the funding to finish it. Im working my tail off trying to get this complete so we can collect final payment. Im going to by a few toys for the shop, first is the HF chipper to experiment with. Ive watched quite few videos and it looks like it might make chips that will work.

Our Indonesia customer just put up a bunch of video off one of the first prototype 25 kW systems.

Getting this very close to completion, I think tomorrow we will have this wrapped up and ready to deliver. This machine is going to perform a finishing process on movie theater chair arm rest that accommodate your beverage and pop corn. So it will be in a daily production environment!!