Looking very good Matt

Hey I got something done before I said I was going to have it done imagine that!!! haha

Yeah I finnished the RnD on the new blower system today and managed to fire that one up tonight.

Ok unfortunatly the smog pump I ordered didnt work. I order two of these and burned both up in less than five minutes. Over a hundred bucks in blowers and poof just like that!!! So I stole the one off the tractor, that one is much more expensive but has already stood the test of time. I set it up with the PWM and it worked perfectly!!

So what I have is a supply out from the blower to a diversion valve. In one direction it supplies air to an ejector at the flare cup and in the other direction it supplies air to the reactor putting it into a positive presure mode. In the ejector mode it puts vacuum presure on the machine for lighting and engine running. If flaring the machine off is desired then you can switch this into the positive presure mode. You back off the motor speed to just 25% of its output power and you can go even less than this. This make a huge difference its efficiency using much less power. If you set up a burner you can use the speed control to tune the gas output. So this adds a new application for this machine as cooking can now be achieved with it.

Im uploading a video I did tonight of it running, I show it flared off in both modes and you can how quiet it runs too. It make much less noise than the older machiens.

Here is the pumps that failed staw away from these; Secondary Air Pump Smog Air Pump 06A959253B

This is the pump are using for now, but these are much more expensive. You will only bey this one once though.You might find this one in the junk yards if you are looking ot save some cost.

https://www.amazon.com/gp/product/B0052XMG8O/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

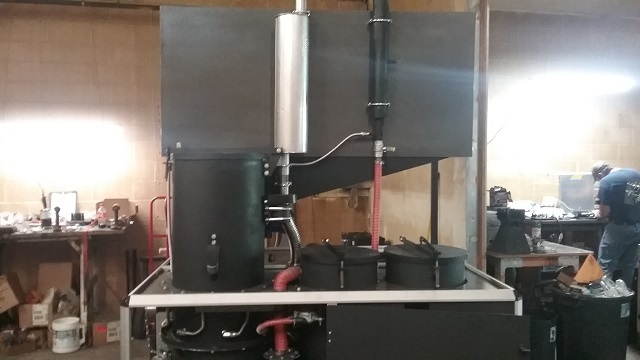

Hi Guys, here I have the other Utility Series I with the full automation package including the mixer control. Wow what a difference, it will run the full hopper load with zero intervention just like the big machines. I also noticed it seems to run a little more efficient as well. I was getting roughly 40 to 45 min on the other machine with a 1500 watt load and the last batch I about 50 min on it. Im going to run a few batches and time it to see if I can keep hitting or exceeding the 50 min run time. Automation is the only way to go

Ok i see the s10 in the background are you planning on running two of those in the s10 or the bigger one you have designed???

I am planning on building a Flex Series III this is the plant we use on the 25 kW machine running the V8. The truck in the background is my daily driver not the one Im converting. This one I plan to keep two wheel drive and it will most likely get an LS-1 with ethanol conversion. Probably will not wood gas that one.

Looking good matt.have you found a fast way too dry the wood chips out in the damp weather wood retreivel.i am having trouble with word sourceing,and this cell phone key board drives me nuts.getting a truck on wood can seem too hit more snags than would think posible, at leaste it has for me anyway.

Yeah Im having issues with the humidity, all my fuel I dried in the sun is soaked again. I have not tested it but I just feel it. Ill have to get a meter on those chips and see whats up with them,

Well just tested them and they are between 8-15% so they should be good. Its so humid here on the lake shore the air will drown you ugh!!

Just was woundering how fast them green wood chips wood dry out in the sun , down too 20 % moister. Seeems like it would be much faster than wood chunks.Lots of areas are low on free wood, chips are free and plentyfull.so keep up hard work after it cools down a little,caint wait too see your truck tooling on wood chips of some sort.

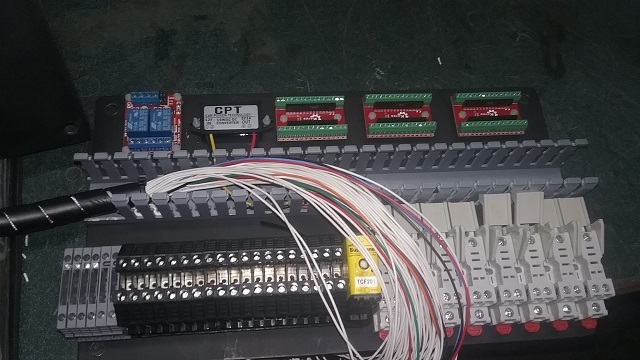

Would you look at all those wires

Well coming along on this guy finally, keeping fingers crossed for first light up this weekend

This is the new Frame we are going too.

Looks real good Matt

Nice neat job on all those wires Matt. Hope all them white wires have tracers on them. Looks like under the dash of a Peterbuilt with all that white wire, of course they are not to fond of tracers.

Yes we wire label everything. I have a guy that is doing all my wiring now, he is doing a good job. This is hard to find its an aquired skill. He complains because the schematic is in my head still haha.

We are going to have an open house on the 17th here at our facility. We will have both the 25kW Evolution S 4 and the 5 kW Evolution S1 up and running for show. If you are interested in joining us we are located at 3140 Whitehall Rd, Muskegon, Mi. The event will be from noon until 4 pm.

On another note, when Im quiet the means Im very busy. haha. Been slaving away on production machines, new development and getting ready for a restructuring of the company. I am going dissolve Vulcan this year with two brand new companies. This is so we can diversify into other renewables and implement better marketing and distribution strategies.

“Thrive Energy Systems”

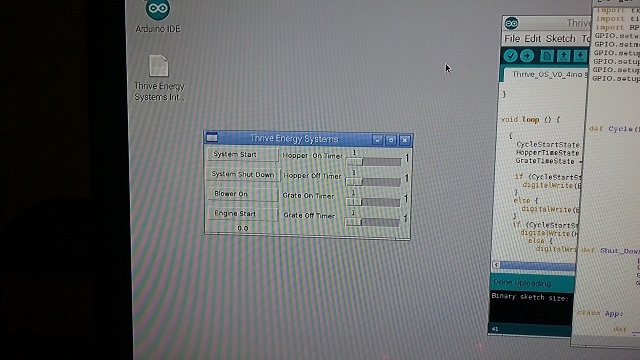

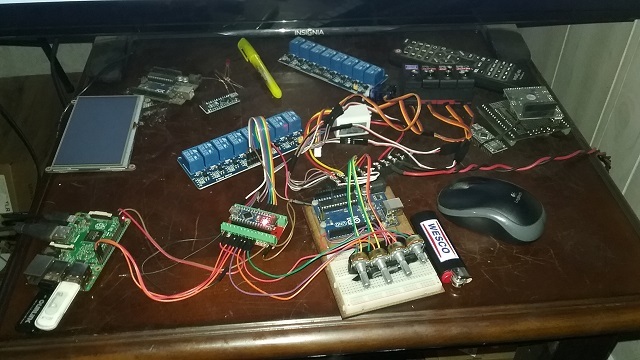

Is going to carry over our Evolution Series Machines and will handle all the distribution. We will add on other wind and solar as we grow this side of the company. The Evolution machines are design finalized and manufacture ready. These machines will have self running capability when we launch for next years product line. They will be driven by the “Thrive Operating System” via touch screen with a graphic interface, These are pc based system with an arduino slave, they will be basic at first with more features on the way once we can get to that development stage. Evolution Series pricing should also drop quite a bit especially the Evolution Series 4 (25 kW)

“Thrive Off Grid” will become our marketing side and we are planning on launching a store front via this website. This will carry over our lower cost units for our own distribution along with the Evolution Series. The Flex R1 gasifier now be exclusive to the Evolution Machines and will be rebranded. We are going to offer the Utility S3 in its place and it will share much of the same plat form. The hearth and reduction will be simplified to reduce its cost. The automation will come as on option to reduce its cost even further. Additionally we will offer our competitors products on our site if they wish to do so. We will be expanding this store much farther than just gasifier systems. This store will offer all kinds of stuff relating to the off grid world. So we plan to be a one stop shop for this market. We will launch both companies in November, the product line will start out small and will grow over the next year.

This is the very early stage GUI, there will much more added including manual overrides, diagnostics and other menus.

Ok I must sleep now

Wow Matt, you have really got it going now. Best wishes to you and your companies.

Bob

Trying to get this thing wrapped up by end of the day Tuesday. Still have some minor mechanical and I need to build the loading platform. So this is our agenda tomorrow and hopefully I can get the machines wired up on Tuesday. Then Wednesday ill be able to begin systems checks on both machines. This will be a first Ive had two machines of this caliber completed at the same time.

Very nice Matt, you can drop one off here anytime for testing .I am busy but would be happy to find time for testing for you. I know you are busier than I.

I wish too, I will be training a guy soon that will do all fianal quality checks, electrical systems checks and then test running. Hopefully he will soon know more about the machines than I do haha

Hi Matt

on last picture you posted

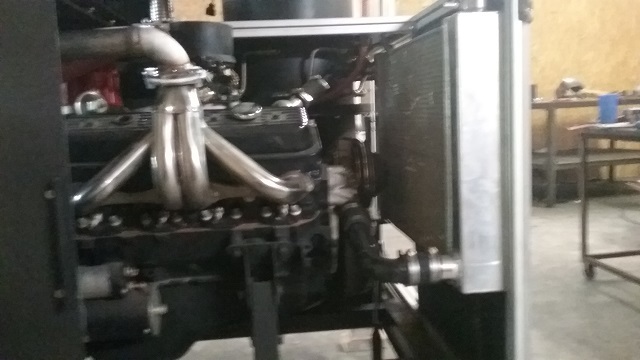

this is an intake manifold that you built yourself? (Stainless steel)

Not sure but I think you are referring to the exhaust manifold? These are block hugger exhaust manifolds that are inverted to make it easier for us the construct the rest of the exhaust.

Oru adaptor is a simple can that mounts to the carb using its stock hardware.