TomH just the need to use a foot pedal switch. Or a knee/hip bump-switch.

S.U.

I hope @Tone chims in. He made a good lengh adjustible forge. Hope he can share some pictures

I wondered the same thing this morning so I sent a PM. Waiting for a response.

JO,

This is my favorite one from Tom which was directed toward you:

“You live under a lucky star!! You do all these things that you aren’t suppose to do, weld stainless to steel, take out the grate, forget to put in a ash clean out, and stuff more than double the nozzles suggested by the old timers and it all works out for you. Now you stuff a rag in a hole and the engine eats it, but it doesn’t matter, the hole filled over with soot. I build right by the numbers and nothing works. I bet when you go fishing the fish jump right into the boat before you get bait on the line.” TomC

An Italian gentleman I knew told me a story one time about a heavy horse he bought from a German fellow. The German asked him several times if he was going to work the horse or eat it… Bruno said work the horse, he needed a horse (Bruno was a black smith too and the story did not make a lot of sense to the German fellow ).

He ate the horse…

The German fellow was mad at him and said he would never deal with him again.

You know what you do have to eat up there we don’t have in Canada? Its those Row dear or Capreol.

Bruno passed away at a ripe old age of 90. He gave me his anvil and some tools with bags of coal because I used to fix his garden tiller and help him out. I wish I had the skill he had. He even showed me how to make a spring…,.

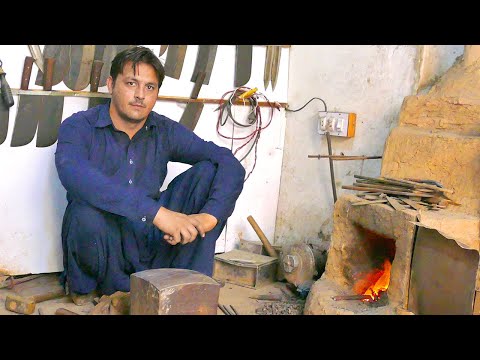

I wish I had the skill some of these people you see on youtube have.

I just had to share this video.

Where do you live, Wallace?

There’s probably a blacksmith organization fairly close to you who has training and meeting where you can learn.

Read this page to see how to get started, if you want to:

https://spaco.org/Blacksmithing/GetStartedBsmthg.htm

Pete Stanaitis

Said one old blacksmith; “one wrong hit doesn’t fix ten right ones”

I will have to look into that when I have more time and Covid is gone. It was just luck I was able to save this stuff. Especially the bags of coal, its sticky coal so you can mix it with charcoal and make a fire you can easily build up and hold together around what your heating ( trick I learn from my chum )

I made an improvised forge out of the bottom of a steel drum and filled it with clay to make a trough. I used a shop vac with the foot switch and dimmer to adjust airflow and I tinkered with it. Ideally i need to get a big steel brake drum and cover to keep the fire smaller and better blower.

I never really made anything with it, Its just been used as a source of heat for straightening and forming rather than real black smith work.

The Anvil sadly is int he flower garden right now, but I do drag it off and use it now and then. Its a good one 110 pound of Japanese steel…

AS my grandfather used to say "best way to never hit your fingers is hold the hammer with both hands. "

I have the blower off a power vent water heater on mine. I’ve tried several others including one that came off a wood stove to blow hot air through some tubing. The power vent one seem to be just above right for volume.

Should be easy to rig something like that using a dimmer switch.

https://www.homedepot.com/p/Lutron-Toggler-LED-Dimmer-Switch-for-Dimmable-LED-Halogen-and-Incandescent-Bulbs-Single-Pole-or-3-Way-White-TGCL-153PH-WH/202746671

I found one of these in my electrical junk a few minutes ago. Perhaps it would work. It is not a toggle switch though, but must have pressure on it to stay on:

Steve,

That’s spdt, simple on/off. A dimmer is continuously variable. I have my foundry furnace blower (old vacuum cleaner) on one. It works perfect.

Use rheostats only on brush type motors. You will kill an AC motor it you put it on a rheostat. If you don’t know what I’m talking about it’s safest to just use on/off switches.

Rindert

Just an on-off switch is fine for a forge. It just has to be located so that you don’t have to look away from your piece in the heat for more than a few seconds. you don’t have the same problems with propane, but I’ve never made a propane forge. I find it questionable watching those guys on Forged in Fire on TV as they push a 3 foot sword blade back and forth though about a one foot long forge and get a quenched blade that is evenly heat treated.

I f you use a blower where you can restrict the inlet that will not harm an AC induction motor. Complicated to rig a trap door you can operate by foot however…

Ya I don’t think they have a decent heat treat on that stuff.

I was lucky enough to watch a my chum who was the kind of black smith that made tools as well as decorative iron work. I will never claim to be able to do what he did, but I could understand it from a steel course I took in college.

There used to be a saying first you get good then you get fast. I feel bad for some of those guys on that TV show that do metal work as a hobby and are probably good at it. The format of the show forces them to rush and make mistakes for drama. It must be really crushing to leave the show on a failure when you know you could have done something much nicer without all that pressure to be fast.

Why is it always swords and knives ect. There are so many other things that could be worked into the show, ask them to make a tool without telling them what to make and the best tool wins…