Hi guy’s,

Sorry for the links to the video’s only…

I will repost after uploading to youtube, with the explanations.

Mea culpa.

The smoke:

Shown in the video’s is just a test setup for obtaining some data.

The next goal is to collect the fumes, and use them at the different stages.

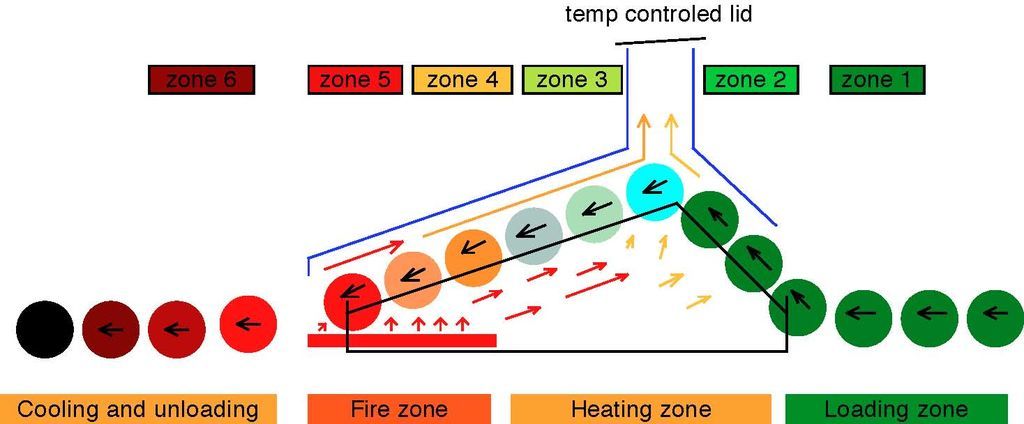

An more optimal setup would be , as presented in an above drawing, with multiple drums which proceed on a railsystem.

The whole plan of my doing is: to use all green waste, charcoaling it in the retort system and use all resources as eficient as possible.

These video’s represent merely the first tests.

The advantage from a retort system? Higher control about the quality of the charcoal , higher yields, higher carbon contents, gas from the charcoaling proces useable as a on site fuel is 150% more powerfull, vapor can be used as water source, the condensate is a good source of energy ( pyrolyse oil )

In these video’s i do use a lot of the available material for the outside heating, nevertheless…

The dwell time for 1 drum (between 60 and 80 Kgs) to turn from wet into full charcoaled material = max 2 hours.

Making a good setup gives you a average from 20 minutes for obtaining 30 Kgs ( using a cascade system with multiple barrels)

Another advantage from the drums in retort system is, i can charcoal even the smallest particles, to use them as fuel afterwards in the gasifier. ( small branches etc… ) even rice husks !!! ( the rebuild lawnmower will be used next as a woodgas driven chipper, to chip the small twigs and branches)

It was and it isn’t the purpose to construct an perfect technical system, but for showing the people around an understandable , ready to copy idea.

Making a simple setup will give people a change to make improvements with there own idea’s and the drive to do things for the benefit of the surrounding nature.

I will post soon, but now i am testing the next trial with the KOGI 2 and the clone Honda 5,5 Hp on a water pump.

If your material isn’t totally dehydrated (Very dry) it is possible to add small dry material to the afterburner barrel (throw it in the top). Use small pieces of wood, or even crumpled balls of plain paper. This is a TLUD, so you want a good layer of charcoal working it’s way from the top of the barrel to the bottom. As smoke is created, it needs to pass through the glowing char, and is consumed. Here are some photos of the setup. The second photo shows the primary air inlets at the bottom. When the glowing char reaches those holes, I remove the bricks which drops the barrel into the depression, and then I shovel lots of dirt and clay over those holes. I remove the afterburner barrel before doing that, and once the bottom holes are shut off, I place a sheet of steel over the bottom barrel and let it cool down. (Third photo.) Let me know if you need more information. Ray (a non-smoker)

If your material isn’t totally dehydrated (Very dry) it is possible to add small dry material to the afterburner barrel (throw it in the top). Use small pieces of wood, or even crumpled balls of plain paper. This is a TLUD, so you want a good layer of charcoal working it’s way from the top of the barrel to the bottom. As smoke is created, it needs to pass through the glowing char, and is consumed. Here are some photos of the setup. The second photo shows the primary air inlets at the bottom. When the glowing char reaches those holes, I remove the bricks which drops the barrel into the depression, and then I shovel lots of dirt and clay over those holes. I remove the afterburner barrel before doing that, and once the bottom holes are shut off, I place a sheet of steel over the bottom barrel and let it cool down. (Third photo.) Let me know if you need more information. Ray (a non-smoker)