Hi BillS

Well the easiest to answer first: then on to the more difficult.

The ASH cyclone SEPARATOR will always go as close coupled to the hearth produced gas chamber as closely as possible before anything else.

I prefer these to still remain somewhat hot so the ash drop out doesn’t muck out from woodgas condensate dropping out here.

Some; do get some actual coarse soots removal here also depending on the actual woodfuel used, the gasifer, the engine gas draw rate AND in my expereince how much the woodgas is allowed to cool here.

Air inlet jets NEVER go in just above the thermal/chemical Reduction zone.

First the air is contolled let in to OXIDIZE some of the premade charcoal to produce ALL of the internal needed HEATs.

Then some of this created heat is allowed to rise up to pyrolize cook out of the fuel wood the moistures and the fuel wood volatile componets. This will leave the then dried out, volitals freed up, fuelwood as glowing HOT CHAR cores.

The majorty of the super hot oxidization zone created HEAT and remaining of controlled let in oxegen will then break down these heat released very long chained complex wood volatiles into now very HOT Shorter Chained Gases.

These now HOT internal gases will be the gasifier internal fuel gasses to then be drawn down along with the gravity downward falling HOT CHAR chunks to make the lower thermal/chemical Reduction zone. You actual desired motor fuel gases are produced here in this termal/chemocal Reduction zone.

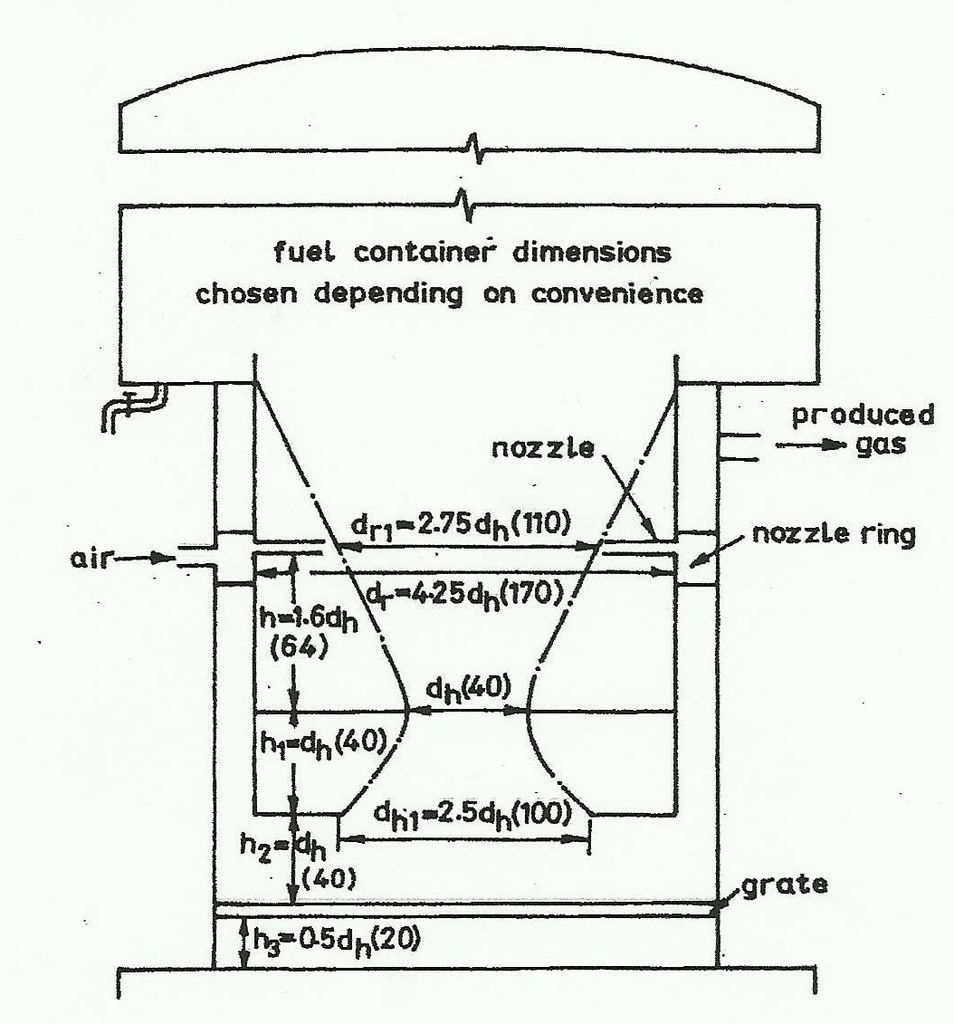

So; you need some space separation from the nozzle jets at the air beginning entry through an Oxidization area to the actual thermal/cnemical Reduction zone for the distance, and flow time, for the oxidization produced heat to drive these initial physical and chemical changes to occur.

Any let-in air nozzle oxegen NOT all oxidization zone USED UP that makes it down into the thermal/chemical Reduction zone will turn it into a char burning up oxidization process instead!

You will turn off your thermal/chemical Reductionand then NOT Make ANY engine fuel gasses.

Be also Oxidizing there now and just make lots of metals killing lower hearth heat.

There is your clue - too HOT of lower hearth heat and you are no longer making Reduced motor fuel gases.

You are now no longer a motor fuel gasifier. Just an overcomplicated char brazier all buttoned up.

I am confused by your wanting to “change my burn tube from 4” to 8"; then say calculations to “reduce this down to”. You just mean recalculate internal volumns and distance proportions, right?

I personally class woodgasifer hearths many functional ways depending what I have to work with and what I’m tring to achieve.

So what is your engine size, engine type and intended RPM and loading useage? Just rough ideas on this. We need to roughly guess-ti-mate the amount of woodgas you will need to produce. No need or use for precise calculations on this. An engine running unloaded to fully loaded will have a minimum of 10 to 1 of actual air and fuels flows needed to supply.

Yep. Yep. There ARE calculators and graphs for this that will get you close for so call Imbert types meaning: High Velosity, Small Internal Volumn Types.

Then calculators and graphs for FEMA types meaning: Low Velosity, Large Internal volumn types.

Neither of these worked-up info base sources account for the very real operational differences in fuel wood species of Volitials vs Carbon (char) vs Ash ratios; air density as affected by altutude and mosture content; heat loses out the gasifier jackets; and many other real world gasifier challenges.

These maths were NOT rigid “Laws” calculated. But actually derived from found to be workable parameters out of many different built up gasifiers. Using them is only a starting point. Many excellant gasifier being used by individuals with great suscess to turn Thier wood inrto motor fuel gases for Thier engine under Thier local conditions that these math bases would say are, “impossible”. Well as I said a LOT left out of these maths.

So just what IS your fuelwood species? And how are you processing it for your gasifer use? Chunked? Chipped? Pellets?

These questions will help narrow down the dimentioning advice to start you out with to achieve your desired results. You’ll aways have to fine tune it in afterward.

Regards

Steve Unruh