I made a bunch of shiplap flooring with my table saw from rough cut lumber. I ended up with a bunch of ⅜ sticks. I did it all in my garage and it was taking up a lot of space. Today I had enough. I grabbed a barrel, lid, and a clamp and started a fire.

I’ve seen Gary G and Don M make charcoal similar to this, so I’m hoping I’m doing it correctly. I kept filling the barrel while it was burning. When the fire went down, I ruffled up the contents to see if I got anymore yellow flames. Once they were gone, I sealed it up to cool down until tomorrow.

I will look for a small can with a lid before the snow falls.

I hope you didnt actually make a hard seal, or your barrel is going to crush itself as it cools. But, making the mistake of leaving the gasket in is a rite of passage  Welcome to the dark side.

Welcome to the dark side.

Good point. I don’t think there was a gasket in there but I can drill a small hole in the lid just iin case.

What size nozzle can I use for a 15hp Kohler?

3/8" or 1/2"?

Still have my crushed can as a reminder. Don’t know why because I will probably never forget it anyway

woop! woop! welcome to the dark side bill…

What size nozzle can I use for a 15hp Kohler?

3/8" or 1/2"?

i would say either…

I think my nozzle (oxidation plate) has a 1/2" hole for a 6.5hp clone.

Thank you guys. I will move forward as I found a can to use.

You can probably just unscrew the small cap/bung, then set it back in the hole. You just need a tiny hole to balance the pressure.

Didn’t Kristian (?) use a tube with small holes in it instead of a nozzle, that didn’t burn up?

Bill, you are going to be blown away at how easy and forgiving it is to get an engine running on charcoal gas. I am the kind of guy who likes to try out stuff before it is totally finished and I could not believe it when on my first try my engine started running after 3 starter revolutions.

Don, I am certain you are correct and will be the reason I have the lawnmower hooked up to the wood chunker hooked up when I light this up.

Hi Bill,

a 3/4" or even a 1" will do best for that size

Welcome to the dark side…

Hi Bill, Go for it!!! I’d recommend a 1" nozzle. 3/4" will probably work too. I find the 1" pipe makes an air tight connection with 1 1/4" sump pump hose. This makes it cheap and easy to route chargas to the filter and engine.

Gary in PA

The other day I fired up my chargasifier and had a flare in 1.5 minutes. The generator had been sitting for a year and fired on the first pull. BUT… this shows what can be accomplished if everything is working correctly. Several minutes later the engine shut down. The intake to the cyclone became jammed with charcoal and no chargas could get through. It took me a minute or so to figure out the issue which I’ve never had before. So, when you are sucking lemons, just stay humble!

Thanks for your words of encouragement Gary.

The charcoal turned out well. The way I’m going to set this up looks like the largest pipe I can use is 1/2". Only because what I have on hand. I guess if I fail, then I will take the drive to town. It’s supposed to snow for the next three days and that may keep me in the garage to work on this. I have to say, I’m a little excited about this.

Bill, I hope you don’t mind if I sneak in a couple of questions here. You seem to have gathered some of the expertise already.

I have to admit I haven’t followed the dark side development very closely. I’ve been kind of busy keeping my daily woodgas driver up and running.

However char is accumulating. The truck produces a bag or two of char every month. Also I have a dozen small 2 - 7.5 hp engines laying around.

If I were to use a 5 gallon propane bottle, what kind of runtime am I looking at?

I don’t store my char airtight, only indoors in paper bags. If I go downdraft or crossdraft, would slightly moist char do the same job as water drip?

Ha, you know l was asking my self when will you decide to join the dark side  carefull, its eaven more adictive thain wood

carefull, its eaven more adictive thain wood

In my experiances you can roughly estimate your char consumption 1l petrol = 1kg charcoal. EGR used. Charcoal bulk density is about 150g/l. If you go simple fire/updraft way you dont need a cooler but your runtime will be somewhat shorter. Cros draft will eat some water but most still passes by. Downdraft will only be cracking if you make the gasifier firetube like.

If you are thinking stationary, where high power usualy isnt neaded, egr is better. The gas is no richer but fuel economy is much better.i burned about 25% less charcoal/100km when using EGR compared to straight air.

Water injection makes wery fast gas but doesent add much to efficiancy.

Oh, to answer the question. It depends  but say you use a 2hp engine l wuld say maybee halp a hour?

but say you use a 2hp engine l wuld say maybee halp a hour?

Jan and Bill,

Here is a photo of a charcoal unit built in a propane tank that uses a 1" nozzle. Run time 1/2 hr. to 45 min, but very easy to add more char via the stainless Baine Marie. I built this in 2012. If you put some slightly moist charcoal in a sealed can, and it is dry, there will be no condensation on the underside of the lid. If so, wipe it off, close the lid, and repeat. Dry char lights quick, and the flare will too. To much moist char makes too much steam in the flare. Water vapor is less dense than dry air, so the water rises, like clouds, to the top.

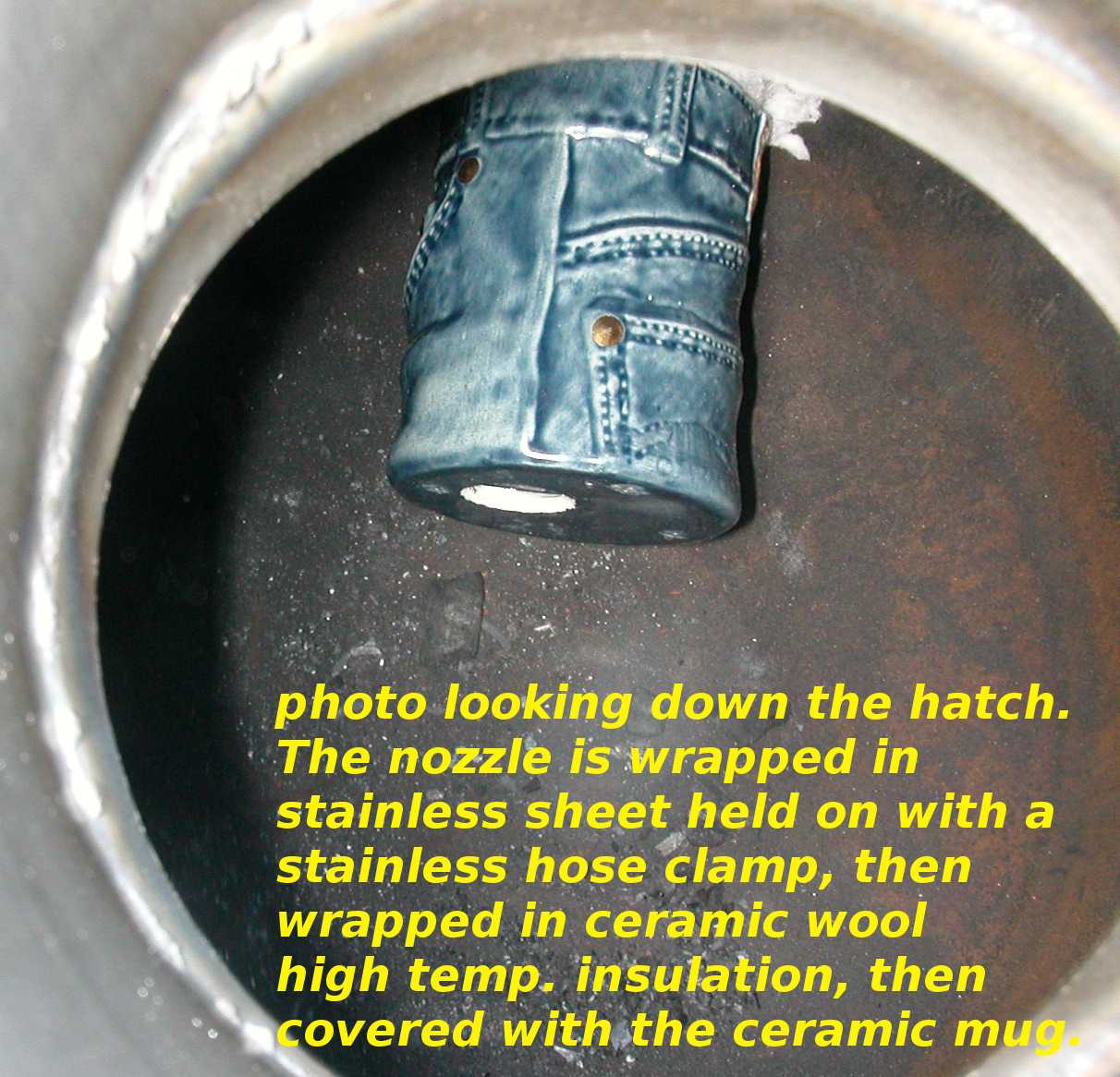

A 1" dia. steel pipe nozzle wrapped in stainless steel eventually melted into the slag, and was replaced and then wrapped in ceramic insulation, and the whole thing inserted into a ceramic coffee cup with a 1" outlet.

I have since made several more spare nozzles using castable refractory around the pipe with a TIG nozzle at the end. When refilling the hopper, I ran a steel rod downward to break up any void over the cup, and accidentally hit and cracked the coffee cup, but it works nevertheless, even with the crack because the ceramic wool is still there. Without water drip, just make a bunch of spare nozzles. The main problem with my propane tank set up is the nozzle is only accessible via the hopper, and my hand barely fits, plus all the char and slag need to be removed and screened.