Many different types seen and used…

Lets show some to compare the pro and con side’s or to teach us which is better suited for person’s need…

Testing my little gasifier blowers, rated about 330 liters a minute, but compareable with the 120L/min compressor is use.

the blower, compared to the compressor, is sensitive with restrictions, showing on the next video, the influence from the restriction from the nozzles in the cooking plate… and the flow, regulated with the small PWM…

As most members know I use the Kirby house hold vacuum cleaner. The pictures show how it is mounted into my system and how it is hard wire to an extension cord for use when I am starting up at home. Notice it has a ceiling light dimmer switch to control the speed / vacuum it produce. In the final picture is an inexpensive Harbor Freight generator I use when away from a power source. Some have used and inverter to run off from the vehicle battery. You can go from “0” inches of vacuum to enough to suck the socks off a fat girl. One builder has hooked a Kirby in with valving so that he can both suck and blow to generate a good char bed faster. ( sorry don’t remember who has done this ) TomC

The Kirby cost me $8 at a Goodwill Store.

Learning by observation…

This Kirby, does it sucks air thru the engine compartiment as well ? or does it has airslots on both sides of the engine compartiment ?

That little genset, is that a 2 stroke ? It looks similar to the small one i use with charcoal gas  ( time to modify

( time to modify  )

)

The good part about the Kirby is the motor ( engine) is totally separate from the fan. The motor shaft goes through a seal and into a “snail shell” shaped chamber with the bladed part in the center.

The little generator is a two stroke. I don’t think I will attempt to convert it to a wood type gas. I would have to have another vacuum to get the gasifier going to feed a gas to the two stroke to pull air to get the gas going in the truck.TomC

Another great thread, Koen. I have used bilge blowers, several different styles of inflators (with PWM) and cheap 12 volt automobile canister vacuum cleaners. The bilge blower and vacuum cleaner only draw a few inches of water column and work OK without the PWM. Gasifiers can also be started by hand (or foot). I have used a vertical inflator hand pump that works on both up and down strokes for constant vacuum. I modified a hand crank forge blower by doubling the number of blades and adding a suction chamber over the side inlet. I’ve also used a foot powered bellows type inflator. We could probably adapt a fireplace bellows to do the trick.

How about a 4 or 6 in. did plastic pipe, 4+ ft long. Seal the bottom end and put a hole in the side just above the sealed end. Put a piston down to the bottom of the pipe with a rope coming up to the top, over a pulley, then down the outside with a weight attached. Attach the charcoal gasifier to the hole in the sidle. light the charcoal then drop the weight and let it suck till it gets to the top. Pull the connecting hose and hook it to the generator and start pulling the starter rope.OMG I’m getting crazy. Got to go to bed.Tomc

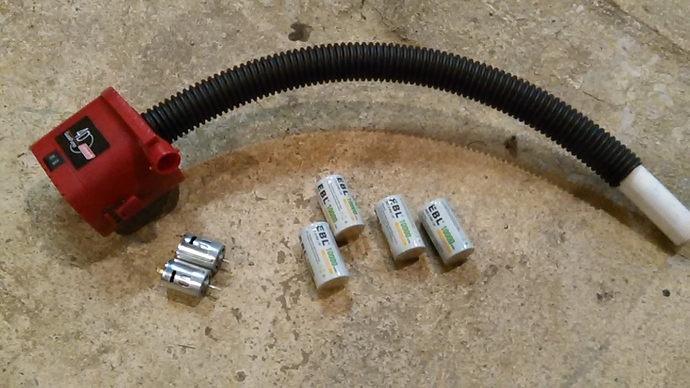

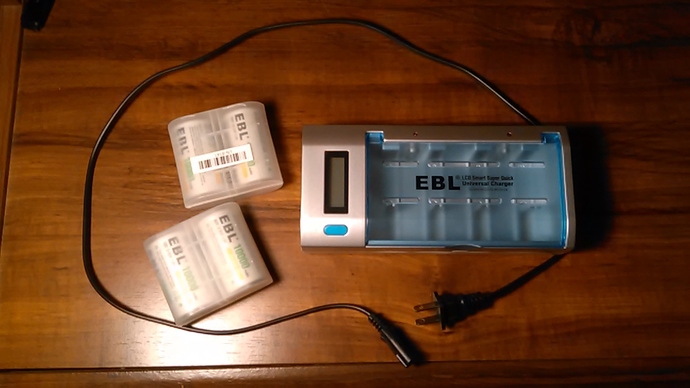

Mattress inflator. Subpump hose fits nicely. Use rechargeable batteries.

Charger works nice and can be powered 120Vac or 12Vdc. Batteries are crazy expensive but seem to be working nice. First charge they get real hot but after that maybe warm. I give each pair a serial number so I can keep pairs together as the years roll by.

Rewired for 2.4Vdc. As one of the photos you can see I have a few spare motors. No air goes through the motors.

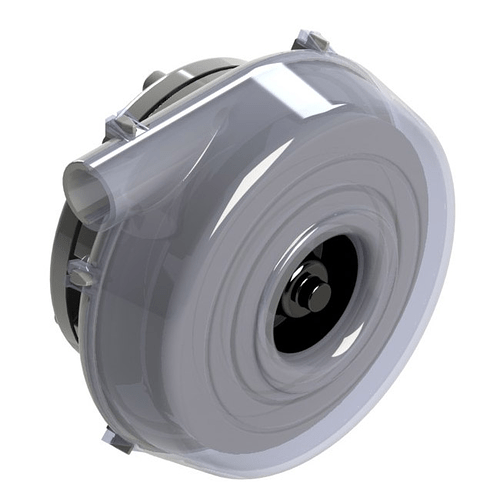

I use a $5.00 12 volt auto canister vacuum from the thrift for charcoal and a power vent blower from a gas water heater for my truck gasifire.

Tom, Did you find a collection of Rube Goldberg cartoons to inspire you?

No I just have a tendency to be crazy. After I post that, I realized that I had actually built something like that to start a Simplifier to run a generator. My mind is really bad. I took something like a 2" PVC pipe and put a 1" inside of it as a piston ( even had “O” rings for seals) then a “T” and I placed solid rubber balls ( super balls) in the “T” in such a way as one allowed air to pass in one direction and the other past in the opposite direct.

Yesterday I was working out by my scrap iron pile and I kept finding things that I had built and wondering, " what did I build that for". Old age is Hell TomC

We used Amtek blowers for the Crossfire… I was incredibly impressed with the power in these little blowers… The downside was the cost ($250+).

I really like some of these other solutions I’m seeing here… Thanks guys.

Troy

Hey guys…

Question for you… I’m working on a small charcoal pipe gasifier to be paired with a small TLUD stove. These will be open-sourced, in the spirit of my first attempt.

The idea for both of these units is accessibility, and affordability to the same (or similar) parts the world over.

Can I get some recommendations for blowers that are affordable and available in most/all countries? Any ideas?

Thanks!

Troy

Mattress inflators ($15), bilge pumps ($20), Wet/dry auto vacuum($15). For a powerful “obtanium” pump use an electric auto smog pump with a 60 amp PWM.

Has anybody considered making a blower? Not so very complicated to do. Can be built from wood metal plastic or a combination. whatever you have available.

Consider this a challenge. See who can make the simplest cheapest starting blower from junk they already have on hand.

I’ve considered making a hand-crank blower, like the old blacksmith forge blowers. But instead of heavy cast iron, would use thin-wall mild steel…After all, you’d only be cranking for a minute or two, right? Just until the flare can sustain…

No batteries, or electrical needed ![]()

I have so many junk fans and blowers from back in the day when we were trying to figure this out. There are so many possibilities now that I wonder what took us so long to get to these.TomC

Any of you guys doing positive pressure air? or are we all using negative pressure set-ups?

Only time I tried positive pressure I was going to try to run a stove but melted my vacuum hose instead. Better have a high temp hose at air intake to run positive pressure.

Troy look to the electric smog pumps. We will now be using these on all future products These things are very powerful and are not passive they can build pressure like a turbo. We are no longer running any gas through our blowers as well. These smog pumps we are using now are capable of running an ejector and do a better job of it than an air compressor. The other method is to pressurize the system and again these things are way more than enough to do this. For now we are using a bypass valve and is perfectly fine, but if you want to eliminate the noise of the blower then consider a PWM. These are automotive so they are designed to live in the engine compartment. So are very tough, but I would still try and design a system where you gas is not touching the internals of it.

Cheers

Edit: I didnt see your last post, yes infact we will pressurize all systems going forward. We use the ejector to put fire to the machines and then switch to positive pressure. Ive also been playing with boosting the gasifier under engine running. This is going to evolve to a full blown turbo on the Evolution machines we should see some power and efficiency gains by relieving vacuum loading.