Well, I got everything put together today, and figured I would let the silicone gaskets cure overnight. Yeah right. I cleaned up the shop a little, tightened all the bolts, and then said, ‘screw it, lets fire this thing up.’

Here is a video. It was really easy to get a flare going with my little hand-cranked blower, what was not easy was figuring out the right number of turns on my valves to get the engine to actually turn over. In hindsight, I should have been a lot more systematic, but half an hour later I stumbled on a ratio that seems to work: 3.25 turns on the air, .75 on the throttle. And away it goes!

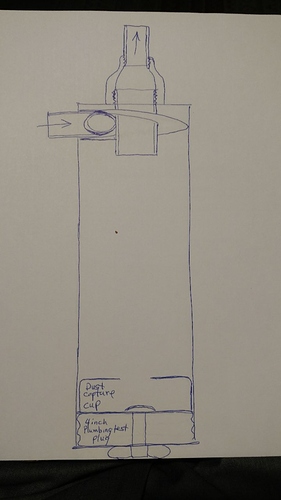

I have ordered a tach to help me dial in the idle, but I think I am going to need to make a few modifications first. With the engine pulling, my reactor thermocouple was registering over 2300F (1260C)! it is only rated for 800C, So I hope I didnt melt it. I might try moving it up higher to get it away from the hot core and I suppose I am also going to have to implement EGR. I also saw a puddle of water forming at the bottom of the hose coming from the reactor, at the filter inlet, so I might add a thin-walled cyclone onto the reactor to try and catch some of the water vapor.

Thanks for the input Steve, I have a couple of 12 volt 35AH SLA batteries that I can connect in series and hook up to it- that should work, right? I am going to mount a panel to the side of the generator for a multimeter, tach, and the kill switch for the engine.

And thanks everyone for the input, I will definitely check out that video about the cyclones.