Here’s a little more info. The one on the right is where this project started. It’s really good for camping, hiking, backpacking. I was using my experience making tlud camp stoves. I just made it with my jack knife. I was amazed at how well it worked, though later ones work even better. The one on the left is just a longer burning version (~36 hrs) of the first one I showed you. Lots of different jars will work, as long you can find a can that fits closely.

Perhaps the Coleman mantle could be made to work with a tlud? A simple wood fueled lantern! Now that would be cool.

Rindert

That is a very interesting proposal and experiment worthy. My luck with small TLUD is no mixed I always get a little smoke and soot out of them and that will blacken a Thorium mantle. The result of soot is no light…

( But if you get the temperature up you can burn it clean ).

Here’s a video on the subject ( this also can happen with pressure lamps but they run hotter and will burn off fairly quick )

You have proposed something now I don’t think anyone has ever mentioned a practical path to wood powered light. But its 2021…

Had this come up in 2001 before the LED revolution this might have had a lot of practical use. India used to be a big user of Kerosene for cooking and lighting. The LED and solar has really changed the lighting equation but its not all that clear if TLUD has changed the cooking one.

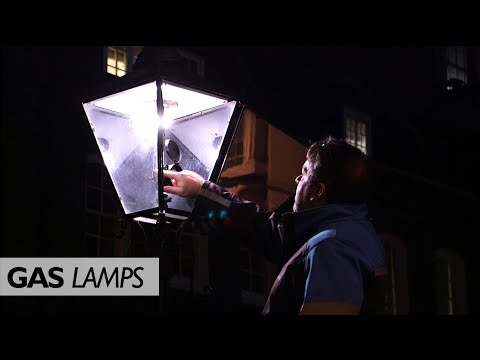

I wonder if its a practical thing to build if you have a small gasometer or cylinder storage system… I would love to get my hands on one of these street lights to play with on woodgas

seeing all these old oil lamps as we called them in the UK has brought back a memory of something i had forgotten all about until seeing Wallace’s lamp and that was my very FIRST ever paid job when leaving school before going to work for my fathers engineering company was making oil lamps here .

Sherwoods , manufacturers of oil lamps and burners in Birmingham. By 1904 they were trading as Sherwood Isaac & Son Ltd ., but by 1920 they had taken over Linley & Co. of 73-75 Great Lister Street, ‘American’ pattern lamps to become Sherwood-Linley. Nechells Park Works, Eliot Street, Nechells then moved to 44-50, Granville St.

I worked at the Granville street factory a big dark ancient looking place with massive power presses on the ground floors and all floors above filled with small hand presses stamping out the wheels for turning up the wicks and all the other fancy smaller Brass parts one of few young lads there surrounded by females operating the hand presses for the princely sum of 7 pounds a week .

I was telling someone how where i grew up was a industrial city and how things had changed and not for the better in my eyes just have a look at some of the company’s here all within a 10 mile radius of the city that worked mainly in Brass and Copper .

https://oldcopper.org/makers/birmingham_brassmakers.php

My area was the same but for textiles. You always had textiles as a fallback job here until the 90s when it got outsourced. Almost all the towns around here are mill villages, small affordable houses made for a 2-3 child family made by the original Mill owners for their workers to live in.

My grandpa made his money selling patents to improve textile production in the 40s-60s.

So the name of the game is clean combustion. No surprise. These last candles have been burning clean enough that I cannot smell any burning whatever, and this has been confirmed by m wife and son. So I consider that an achievement, for me anyway.

But a very clean tlud, like that, seems completely out of reach at this point. And I wish those mantels weren’t so fragile. I am tempted to try to do something with good high temperature charcoal in a nano chargas generator… I just wish I had better maker skills. It will have to be very simple if I’m going to make it. Anyway this has been a nice pipe dream. Thanks guys.

Rindert

Had a record breking charge today. Over 200 pounds of ringing charcoal just like this. Thats about 600 miles worth of engine fuel. Not bad for just a couple of hours of work…

Wow that is remarkable, sounded like glass breaking!

Hi Kristijan

is the wood you are cooking very dry?

Not at all. Its been pushed on a big pile by a buldoser a year ago. Overgrown with vines. Thin stuff is dry but anything biger thain 3" is still almost green.

it’s quite surprising how good your charcoal is made from wet wood. I guess the mass effect of this big oven has something to do with it

Did the tank you used to build the oven already have this large door?

I think the main reason is good insulation and big surface area of the inside heater. All heat from the heater is used to boil the water out, oposed to the old Kursk that lost a lot of it to the ground. The amount of steam that rushes out when the bach is warming up is amazing.

Its a old manure slurry spreader

It’s great I’m looking for one of them today. If I put iron skids on it instead of its wheels, I could move it on the forest cut beds and carbonize the crop residue

Dont worry about the wheels. Even when the Kursk is at its max temp the walls just get warm. 15cm of mineral wool. Ataching it to the tank might be a problem thugh for a mobile unite…

At home in my garden when i use my “Hookway” style retort on fallen branches up to around 2 inch dia I some times can get a nice glassy sound not as nice as yours though , but never when i use old timbers from say hard wood pallets or hard wood blocks , that’s very interesting as i have always known that the indirect way creates that hard ring type charcoal , but then if you see how they make the Japanese White charcoal that’s just amazing and as direct as you can get .

Insulation is major factor into any type of retort keeping the heat in and also a longer more even balanced burn i think makes much better charcoal , if i am able too during this winter season i shall have to try and experiment , but i doubt i will get mine anywhere near as nice as Kristijan’s .

Dave

mineral wool will not hold up in my experience. maybe rock wool could resist!

I have mineral wool and it holds excelent

The only sound my charcoal makes is a dusty thud.

Mine too Steve so your not alone

Kristijan , its pretty early here and so i decided to re read best i could what you had put down about the Kursk , my eyes are not what they were and so your photo’s lacked the detail i needed to see , so would you mind explaining how this is working , do you fill your feed stock under that half drum inside and then just keep putting more rubbish wood in till it self ignites ? or do you fill that half drum up and then surround it with larger branches on top and sides and start a small fire at the front and wait for it to all just burn down .

Excuse me if you have already mentioned how you do this already ,i just have not seen any detail as yet .

Dave

Hi Kristijan

you put mineral wool under the fireplace inside the cistern? to protect the bottom plate from overheating I presume?

the pyrolitic gases enter the hearth through which orifices?

I really like your plan to condense the Kursk smoke