I have looked at what it looks like between the wood container and the fire pipe, on JO’s old he has an 8 “fire pipe and mine is 9”, so that should not be where the problem lies.

Thanks for the description on the meter, will try to get something for testing.

Have you ever set fire to your intake? I’m a little scared to set fire to the intake, do not know how the sensors react.

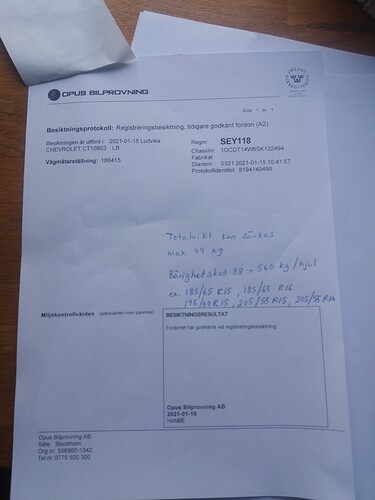

Now the car is legal to drive with, inspected today, I have been on petrol completely unnecessarily for over a week, they did not test the values of the exhaust gases.

Congratulations!

Did the have anything at all to say about the gasifier?

Did they put you into the flexifuel category as well?

How much curb weight did you put on?

The guy who inspected the car had never inspected a gengas car, he tried to call the one who inspected your car, but he was in a meeting, so there were no comments about either the unit or rubber hoses that I have under the car.

The car weighed 200kg more now, I think it sounds a lot.

It became petrol and gengas in the papers.

I can only pull a trolley that weighs 1170 kg after my car today.

But if I put on tires that are not allowed to carry as much load, on the car, the inspection can classify the weight down which i can load on the car, which means that I can pull a heavier trolley. (total weight)

So the inspection guy helped me with which tires I need.

Same as mine. I was surpriced too. I would have guessed half of that.

That tire thing is different from what I ran into in the states. I needed new tires and the dealer would pass up a sale, becaise I wanted to go up one size. He said it was breaking the law to put anything but what was on the door sticker. (?) TomC

I have made a new cone in the wood container and a new restrictor, the same size as before.

Cone goes up about 25cm (10 ") on the wall in the container.

Now we were out and drive about 50km, the car does not run quite as usual, and I only get about 1/4 of the water that I usually get in the condensate from the wood container.

Have also installed an electric stirrer for the wood, seems to work like that.

Hi Jan, there are a few ways to do it. If your wood is above 18% moisture content I will pore the charcoal on top of my feed bag of wood. Mix it 1/2 bag of wood to 1/4 charcoal. 3/4 of a bag is all I want to lift into the hopper. I have also put wood in the hopper after light it and put charcoal in the center of the wood about the same ratio. Every gasifer is different. Kristijan will probably give you his mix ratio.

Just play with it. My charcoal is popcorn size and larger. I have used the charcoal out of my gasifer after screening the ash out of it. The smaller charcoal will fall right down in between the wood pieces. It also gets rid of the sticky tar.

I should have posted it on your thread soory. I look at this way, the gasifer made all of this good charcoal why throw it away. Just use It for more power it makes Hydrogen when it has moisture in, and it will absorb tar vapors and uses it to make more power. It is a win win.

Bob

I have tried to drive about 60km with a con in the hopper and then drain the water from the tank on the hopper and the tank on the radiator.

Then took out the con and put a grille in the bottom of the hopper, and drove about 60km, this time got about twice as much water from the hopper tank, but less amount of water in the tank from the radiator.

One question to you @Wayne Mr Wayne, had you tried with 1 and 2 hoses between engine and cleaner?

Was there a big difference in the power of the engine?

Hello Jan .

Between the gasifier filter and motor I have 2 pipes each having a shut off valve controlled from the cab.

Normal operation I can tell no or very little difference from operating one or both. At heavy throttle I may be able to detect a little difference in the vacuum gauge reading.

One of the reason for having the two pipes is I can kill one of the pipes at heavy throttle and feel the performance and the reading of the gauges . Do the same on the other pipe and if the two pipes are not equal something is wrong. Could be blockage or air leakage.

Also by having a parallel cooling system ( cooling rails ) I can block one side and then the other and compare the two to detect any blockage or air leaks .

Aha, interesting, I ask because I think my car is weak when I pull heavy trailers, it runs pretty well otherwise, does at least 100 kmh, has not dared to drive faster on my roads.

My oldest boy is helping me with vaccum sensors, I hope I get more help then.

I have received some good advice from JO, and started on something that the wood does not stick to, I hope.

Wow, I just pressed reply and you’re already half way into the build

More questions, the lighter you use, does it work in the cold?

I have been lit with paper for two days, now that it is -20C (-6F)

Do you usually cover the coolers a bit in the cold, I have read in old papers that they did it, but do not know why.

If I make a fire tube that is 30cm in diameter (12 "), will it change anything because nozzle will sit about the same distance, (the diameter of the nozzle circle), (

Jan, my torch doesn’t work below -10C either - if it’s less than half full.

I’ve never covered my coolers. Condensation seems to just barely stay above freezing.

I’m curious - what happens to your foam in these temps? It’s even further downstream the cooler. Does it still breathe in these temps?

I don’t quite get your last question. Will you be using longer nozzles and still have a 9" nozzle-tip-circle-diameter?

It was -23 this morning. I cancelled driving today, stayed inside and watched summery chunking videos

The foam seems to work well, I looked yesterday in the barrel and it lies nicely against the edges, if it gets tight it should lift after an edge.

I put in the leca balls instead of hay, and it became to breathe much better, it froze on the bucket at the bottom when I had hay, to see how good purification it will be, it looked good yesterday in the intake.

Yes, I have 9 “fire pipes today, and the nozzles are only 1/2” approximately and according to the books I will have 9-10 “in diameter between the nozzles in a 12” fire pipe, there will not be much difference, and as Kristijan says, it should be the measure that controls how big the fire pipe is.

Does anyone have an idea why my cyclone suddenly stopped working, there is almost no soot in it?

I have stuck a thread through the ash hatch up into the cyclone, so it does not seem to be tight there.

May suck air from the soot sump.