Thanks Michael, I haven’t had a thermometer in the wood before, so I don’t know where I should be.

JO has a similar container as me, but he is around 80 degrees c.

Discussed it with him yesterday, and we concluded that we do not have the thermometer in the same way.

Good morning Jan .

My fuel hoppers may be a little different than yours or JO so my reply may not be much help.

My hopper temp will run 160 F or below until the need for more wood. I paid extra attention over the weekend of about 75 miles so that I could report back to you. Late yesterday on a 10 mile drive on the open road the temp went up to 140F and after a few minutes idling around the pasture the temp went up to 160 F.

Just put down another quick 25-30 miles . The hopper never went over 140F

Thanks Wayne.

I have tried a bit today, and my temp hikes between 80 and 115 degrees c today, if I shake with the car when the temperature is high, then the temperature usually goes down, seems like it builds bridges all the time.

I only have 40cm (16 ") between the thermometer and the nozzles, I think you have more?

My wood is very dry and light, (pine and spruce) so JO is probably right that I need some birch to make it work, or if I have too large pieces?

My thods. You and JO have similar hoppers and gasifiers, but your engine is allmost twice the size. You measure the temp on a different spot too.

The real question is does it work as it shuld? Enaugh power? If yes, l wuldnt worry about the temp.

I vote yes for smaller fuel anyway. Go with wallnut size, if it works good, progress to bigger and bigger untill you start seeing problems, then you know your limits. Mixed size fuel is great allso! Helps with bridges too.

Jan, I payed special attention to the hopper temp today.

I left home with a full hopper. After close to 20 km or 20 min I made the video and the temp had slowly climbed to 57C. A few minutes later it leveled off between 70-75C.

I had 4 different arrends around town. I shut down no more than 5-10 min at the time and the temp stayed put between 70-75C.

After 1h40min and a distance of 48 km I was back home again. Only 2 km before I reached home the hopper temp climbed to 85C for a minute, but went back to 75 again. I imagine chunks hung up on the funnel for a short while, but caved back in. I expect to have a little more wood left in the hopper than I like at next lightup.

Fuel used was mixed species. Willow, mountain ash, birch and pine. Size, between thumb nail and egg + some smaller debrie.

Thanks JO, tested mine today about 20km, it rises to about 80-90 degrees c after about 10min from start-up.

Then it commutes between 90 and 105 degrees C, tested to run for 90 kmh, and then the temperature went up to 115.

After 20km the temp rose to 130, and I stopped and looked at the hopper, there was wood left but almost a hole in the middle, loaded some more wood and went home.

I have no wall in my hopper (I took out the cone), I probably have some larger pieces of wood too, only pine, my reduction is only 100mm too, so maybe my should be warmer than yours?

Rides mostly at about 1600-1700 rpm, and 4.3 liter engine, gears at about 2400-2500rpm, wondering if I should increase the reduction, it’s not that strong now.

I get a little jealous of you and @Wayne who can go all the time without problems.

How do you separate condensation from wood and debrie?

You mean the restriction, right?

Maybe you could increase it just a notch, but with the size of the firetube you will be pushing limits. I doubt it would make much difference. Maintaining 80-90 km/h on flat ground without overheating is about all what we can expect from our small gasifiers anyway. Your engine can do more, but the gasifier will start producing bad gas if pushed harder.

There are constantly “problems” we all have to avoid. Whatever the gasifier tells us, we have to comply. The earlier we do that, the less consequences.

We’re lucky to be able to fill in the small gaps in performance with gasoline. That’s the easiest way and for the most part it’s only about a few drops. On yesterday’s ride for example, with 4 shutdowns, I may have added gasoline for 30 seconds in total, but it saved me a lot of trouble.

Driving 100% wood gas in today’s society can be very difficult . Driving 99.9 % wood can be all smiles ![]()

I have a grate in the bottom so the wood does not come down to the gutter.

Don’t you have 110mm restriction JO.

I probably have to plug in pwm, so I can run with some gasoline when needed.

A new question, this morning I was driving around some forest roads, driving slowly and looking at the animals and birds, had almost only gas, only a little secondary air.

I don’t think I get it with the air, if I pull out the air too much, it will take a long time before the engine comes back.

When I would start the car in the afternoon, so I drove on gasoline, it was to smok very out of the exhaust pipe and the engine went bad, it seemed like it was wet.

Could it be the gas mixture in the morning that caused this?

I sayd it before. I realy belive your problem is a hot leak somewhere. Fits all the simptoms.

If there is a leak in the hot part of the gasifier (leaky ash door, fitting, pipe connection, weld…), even a tiny one, the engine will suck air in the gas. When air meats hot gas it instantly statrs burning. This produces H2O, weak and hot gas and forces you to push on the gasifier harder wich only makes things worse!

Since part of the gas burned, it is lean so it needs less secundairy air and more gas, again pulling more on the gasifier. This may allso cause your high temperatures.

Its either that or you use inpropper size/shape/dryness of wood.

Thanks Kristijan, I have tested with water and soapy water and have not found any leaks (yet).

I have no ash hatch, only outgoing gas pipes, but it can leak between the space of the nozzles and the ash part, I tried this space with water before and found nothing, but may have cracked afterwards.

I have taken down the size of the firewood, but have nothing that is like a thumb nail as JO uses, after that it became the car to work but not so good

.

Yes, I have - with a 10" firetube. First year I used a 100 mm restriction, but it started to get oval and worn out. I changed it out for a 110 mm. Couldn’t tell any difference in performance even though the csa increased by 21%.

To me that would indicate I have a very tight charbed or a plugged grate - OR additional air is already entering where it’s not supposed to. Worst case in a hot area where it can catch fire.

Hm…can’t tell. A rapid response on air setting is what I’m used to.

I guess you read about what we call an EVENT. It’s when small flakes of soot let go and get stuck between an intake valve and its seat. This causes soot to start burning in the the intake, with a smoky exhaust as a result. That would be my first guess.

Second guess: You made some tar. Have you at some point felt a sticky throttle? Tar could make an intake valve struggle for a while, with the same result.

I experience events from time to time, but never during winter. I’ve come to the conclusion the gas gets dry enough (due to better cooling) that only fine dry soot enters the motor. With more moisture in the gas in summertime, the soot sticks and small flakes/lumps let go now and then.

Jan, I see you installed a vacuum guage finally  Wide barrel means low vacuum - thin barrel means high vacuum

Wide barrel means low vacuum - thin barrel means high vacuum

I had the exact same accident happen when I first mounted my barrel on the VW pickup. I was forced to reinforce my barrel with rings of rebar. Which reminds me I forgot to check the rings out when I did my annual hay change two weeks ago.

Is the charcoal bed too tight when it sucks the barrel together?

Could be. Maybe in combination with the grate partially plugged with ash. Happens easily with a lot of start and stop or slow driving. With no grate shaker the cure is to let the gasifier stretch its legs with some open road driving. 15-20 minutes of hard work should make the charbed clear up. Or put your poker down through the char to rattle the grate a little at next lightup.

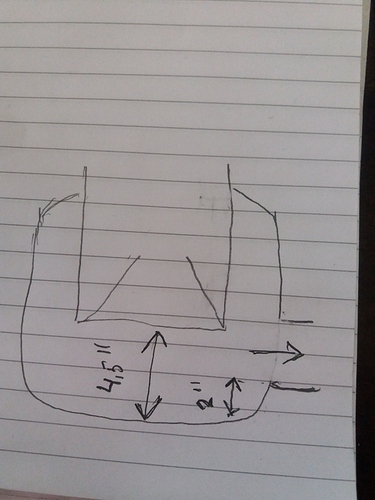

One question again, I have 4.5" between the bottom and the fire tube, I have no grate under the tube.

It seems that the carbon bed gets too dense easily, is it because I have too little space in the bottom, or is it because I fire with pine, and not birch.

JanA., you would benefit much by adding a charcoal holding up grate.

This can be easy to retrofit.

I’d suggest a 4 chain hanging grate. The chains as long as possible up to the top of your indicated outer gas space. This will reduce the hanging grate Up-swing to minimum. You can use angle iron bars with the V upright to ash-protect collect. I’d suggest a ~35mm perimeter grate fence ring to retain more of the charcoal up in the active use zone.

Below grate charcoal is pretty much inactive.

A simple smooth through rod to the outside trough a ferrule clamp tube fitting could be your “needs” grate shaker.

And move your gas out port up high into that gas space to reduce swept out char-soot.

Your original gas-out port can then be your lower cleaning out port.

Regards

Steve unruh

Too small around 1" round wood lite wood has tendicys too stick too the hopper in some cases, my small wood test would burn about half the wood down the midle and the rest sat close too the hopper walls, then again i was useing a heated hopper design unit test, running pine branch wood.