Maybe too new or too nice to experiment with? Diesel?, or Benzine / Petrol /Gasoline engine?

i can understand you reaction, i have a friend here from Russian, he can not englisch

he is interesting in that, so i like know what is possibel.

and so far i understand, i can not learn me friend .

you can show him this, then he can read most of what is here

https://translate.google.se/?hl=sv&sl=ru&tl=en&op=translate

( diesel/gasoline mix) perfect fuel for running on mixed fuel with woodgas…

nice

мир think bigger . all the old tires

Doing bigger already…

Diesel and wood gas, this is the best combination for me, some time ago I converted an older Ford to which I added LPG, in direct proportion to the lever on the diesel pump I controlled the valve for LPG, which mixed with air in the venturi constriction in the intake duct, power there was a significant increase in smoke on the exhaust, but there was practically no smoke.

I intend to supply my diesel generator with wood gas, plan in brief:

-on a vacuum gas mixer on the intake manifold, similar to the one I have made for LPG, only a stronger spring and a different ratio Gas "carbourator"

-diesel pump limited, so that the fuel is sufficient only for idling

-The speed regulator will open the air damper (air / wood gas mixture), I hope I will be able to install the connection between the diesel pump regulator and the air damper

The high compression ratio greatly compresses the gas-air mixture, which is also heated due to compression to 400-500 ° C, a small amount of oil is injected here, which further raises the pressure and temperature during combustion, the combustible substances of the mixture ignite and burn in an instant and completely, even if the mixture is poor. Combustion is actually a controlled detonation.

Ford 1.8 diesel with the addition of LPG

a little more loading and advertising of the diesel engine

, with newer diesel engines, experts lower the compression ratio, especially with Mazda, and the fuel injection is changed, ie only one injection at the top, so the fuel is distributed and mixed over the entire volume of the combustion chamber and burns in an instant. An even better effect is achieved if we pre-prepare a mixture of air and combustible gas with a slightly depleted mixture and when we inject oil into it, it burns instantly and without smoke and harmful NOx. I believe that the engine also develops more power than with oil alone, as gas contains more H atoms, which need fewer O atoms to burn than carbon oxidation. Even when adding wood gas, the engine should maintain its rated power, … I have to do a test as soon as possible and I will report the measurements.

My opinion: in the future most people will use dimethyl ether fuel in this kind of engine. And a few of us will add woodgas as Tone says here.

Rindert

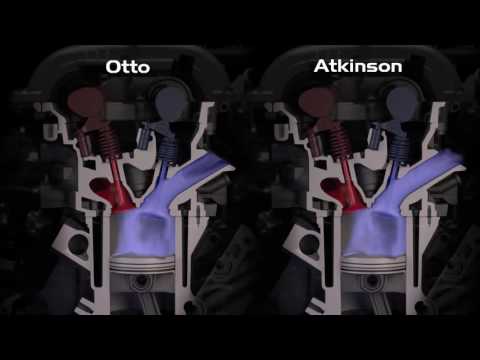

The diesel engine is by its design compared to the Otto engine, as one friend of mine said, a completely different beast in the woods, but each has its drawbacks. With the Otto motor control, the efficiency drops drastically when operating at low loads and is not good even at full load, it works optimally at around 70% of charge, which people have found out a long time ago and try to emulate modern engines.

Disesel, however, has a problem with incomplete gasification and mixing of fuel and air in the combustion chamber, where there is no complete combustion, and at partial load, when operating with excess air, the formation of toxic NOx gases. Due to its relatively high compression ratio, it has a much better efficiency, large two-stroke marine engines even over 60%.

The world is not black and white, so both operating principles have their good properties, which can be easily combined in the construction of a diesel engine with high compression and thermal efficiency, Otto cycle with a slightly poor mixture of gas and air and intense detonation ignition with diesel fuel.

I’m loading a little, …

I had a diesel and I turned my nose up to the technology because of lies VW told. This was upsetting to say the least when you think are suffering in a freezing car in the winter for the benefit of the environment . I never looked at a VW again untill they made noises about going electric.

TO THAT END…

I think NASA was onto something with the 80s stirling technology. With today’s electronics and hybrid drives I think its reasonable to assume you can have a warm car that’s clean and can DOW without significant modifications.

The Stirling Engine that would make IC Engines obsolete and put a big cut in the greedy oil lords pocket books. No oil changes every 3000 miles that alone would cost them billions of dollars in oil profits. Higher gas mileage more monies at the pump they can’t make. One spark plug, no muffler, no catilic converters, and all the other things to pass emission standards many more billions of dollars.

All the oil lords just had to do was greased the right people in goverment to stop it.

NASA can use it, but not the public. That is if the Stirling Engine was really what NASA said it was in this video. They would never lie to use would they?

Bob

Bob:

I think its just a simpler case of the engine is too expensive to manufacture compared to a traditional IC engine… Could you imagine the pleasure in driving a hybrid electric Stirling and the peace of mind of a gasification system that did not have to perfectly produce tar free contaminate free gas all the time?

Just pure magic, and if the power goes out you just fire up the truck and the stirling and battery pack could do double duty and power your home…

I think with today technologies and the way we build things it would not be that expensive, look at the automation and robotics in manufacturing now.

Did you notice the different types of fuel that could be used. Could it run on wood gas easily? If the answer is yes then that would be a big problem for the oil lords.

Bob

Here’s a couple more videos on the subject Bob…

Yes it can use any external heat source even solar energy if the heat is collected and concentrated. NASA’s interest has been to use Stirling technology with a nuclear source to power probes.

This would never have been built had it not been for a GOV tender for a generator to power a military radio in the 40s with any kind of fuel…

People still working on it.

I went off topic a little sorry…

O.K.

Bringing this back to reality-practicality:

the real quest you should be asking is “how much better can the internal combustion piston engine be developed?”.

In the years from these 1960-1980’s; toss out that dirty IC piston baby; to now . . . this has what has been done by the real put-to-works engine manufacturers.

Fuel to work efficiency increased by 50%.

Actual average useable life’s before machining overhauls: doubled.

Exhaust emission decreased to 5% of what is was at the time of these video’s.

Why did not NASA themselves use modern Stirling’s in their spacecraft?

Vibration. Would have upset precise dish alignments. PV solar was the way they went closer in.

No vibration fuel cells for the longer out probes. And the manned moon work.

Why did private industry not go back to external combustion with modernized Stirling’s?

Fuel use economy still cannot match the evolved latest IC piston engines. This has been a moving target.

If Stirling really could actually do it better; it would be powering freight rail and the ocean bulk shippers. They would practical $$$'s savings forced this into usages. Staggering economies of scale with quite the prize for actual better in these areas.

And the Chinese, Indians, Japanese, Korean engine/power plants manufactures with NO domestic Dino-oil would be leading the change over charge.

Nope. Just making better and better IC piston engines.

You all really need to read and study the 14th Chapter of C. Lyle Cummins “Internal Fire”:

Rudolf Diesel: The End of the Beginning

A balanced harnessing of Pressure-made-by-temperature; will always beat out an unbalanced Temperature-to-make-a-bit-of-pressure approach for working shaft power.

Let me give you the real working numbers for my last bold statement.

Modern IC piston engines at cranking generate 175-450 psi BEFORE the fuel is added.

Combustion they in cylinder working pressure spike at 1200-3000 psi.

Modern Stirling’s in an attempt to keep up try to drive their Hot-end continuous temperatures as high as 2200C/4000F. To create working pressures of just 450-800 psi.

And remember they must hot-back-to-cold cycle their internal working expansion gas to produce working power.

How many cycles per second?

About 1/10th the cycles that a modern IC piston engine can do.

Back in the 1950’s a couple of very good engineering brothers attempted to modernize reciprocating steam to beat then IC piston engines. They were running up their steam temperatures so high their metal cylinders were turning translucent able to see the shadow of the moving piston. Obviously unstainable material destroying temperatures. A Fail.

In the early 1960’s Chrysler really did have installed gas turbine engines in production chassis cars. Testing. On roads driving. Multi-fuel gas turbines. What happened? Fuel economy sucked. They could keep engineering for durability - and heat recovery - but fuel economy just could not match then current IC engines.

Then the many companies Wankels developments. Even into actually production buyable, ownable vehicles. What happened? Fuel economy sucked in comparison to then IC engines. Throw 100’s of millions $'s at it still not a wide use workable to knock off IC’s

Fuel cells in production sized vehicles from at least 2-3 mainline manufacturers. Why still “in development”? Durability. Fuel sensitivity. The best performing still want just pure hydrogen.

Obviously now modern electric can match IC piston engines.

With even more then Central-Down “We will decide for you” energy dependencies.

Nope. Woodgas IS the only actual personal energy freedom fuel. And the current in-use IC engines are our best make-power users of this fuel.

Waste time on woo-woo N-e-x-T engines.

And that welder fabricator fellow will be running circles around you with converted IC piston production engines at a fraction of the words, hours and expended efforts.

Just the facts of it.

S.U.

Well said Steve, no system or engine with external combustion can achieve efficiencies like an engine with internal, just physics. Large marine two-stroke diesel exceeds 60% efficiency, Detroit diesel also made interesting two-stroke engines in America, I also have a two-cylinder two-stroke diesel engine on my Holder tractor and I can say that it consumes very little and develops good power. The thermal efficiency of high-compression engines is reflected in the fact that the exhaust gases are quite cold, unlike, say, ordinary Otto engines, where the exhaust pipe literally glows. The VW company really cheated with NOx emissions measurements, but as already mentioned, at partial load all diesel engines have these problems, for which one of the solutions is the combined Otto-Diesel process, for which wood gas is a good choice.

SteveU. Somewhere around 1974 GM build a whole Wankel section in their Hydramatic transmission plant at Willow Run. I was involved with the conveyor installations. As far as I know they never sold an engine off that line and then a few years later tore it all out.

Also IC is simple. Anyone can work on it. There are millions of salvageable parts available. Not so with turbines or any of the other new engines. So if a person is really hoping to be some degree of self sufficient it’s the only way to fly.