Would anyone here be interested as far as the second gen dodge trucks we love to woodgas with 94 and up like to learn a great and cheap way to get rid of the very problematic dodge unit bearings on the front dana 60 axle? I recently did a free wheel hub conversion on my 94 v-10 and if the knowledge would be helpful to others I’ll gladly share it here

I have a 2000 Ram with Dana Axles. Have never had any problems with them but I’d certainly be interested in doing some preventative maintenance.

Basically if your dodge looks like this

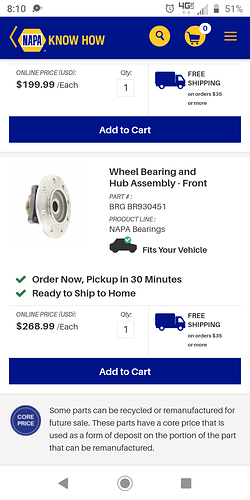

And you don’t want to spend this every 60,000 miles for aftermarket junk

Here is the farmboy way to fix it.so the unit bearing is a weak point in these trucks and aftermarket ones are terrible for price and iv spent plenty of time arguing trying to get them warrantied. So dana 60 axles haven’t changed much in there 70+year production run so here is what we can do. Obs series ford’s 92-97 f250 dana 50 twin traction beam and 92-97 f350 dana 60 ball joint front axles have the desired parts. Removable spindle assembly, replaceable bearings and seals. These parts create a serviceable front axle that parts can be had for dirt cheap at just about any parts store instead of year make model specific dodge parts. First step is getting the parts, I found everything I needed at just my local wrecking yard on a 95 f350 diesel. Unbolt hub selector, remove where bearing nuts and bearings, slide rotor assembly off. Unbolt spindle from the knuckle, and separate the outer axle stub shaft as we will need this as well for the conversion. This stub shaft can be had out of early chevy dana 60 axles as well, it is 1/4 longer then the Ford dana 60 and will interchange just fine. The Ford twin traction beam dana 50 axle stub shaft will work as well but is a 1/4" shorter, so you won’t be able to run the axle retaining snapping inside the hub. It really doesn’t do anything but it matters to some people so figured I would throw in that little tid bit of information. So now to tear down your own truck and prep for the parts swapping

My truck in particular didn’t require to much to take apart as every component was junk. The unit bearing split in 2 after removing the outer axle nut and fell off

Ball joints were dry and wasted so I replaced these while I was in there

Removed the knuckle off for the ball joint replacement and slid the axle shaft out

So onto cleaning up my junk yard goodies now the truck is tore down

Pressed out the wheel studs to seperate the rotor off of the hub body. And removed all the grease from inside and gave it a good scrub in diesel fuel

Spindle itself got the same degrease treatment. Don’t forgot the roller axle needle bearing inside it needs cleaned out as well

Wheel bearings all get a good degrease and scrub out. Seals that were removed from the Ford are cleaned up so I could get part numbers for the replacements at local parts store. This included spindle dust seal for the axle shaft and hub to spindle seals

The Ford spindle has a lip on the back that allows it to press fit into the Ford knuckle before it gets bolted down. This lip is the same diameter on the dodge knuckle so it sits right in place

The Ford spindle uses 5 studs on the knuckle to locate it in place, while the dodge knuckle uses 4 through bolts. One hole is very close to lining up so I used a carbon burr bit to open up the hole and use the factory dodge unit bearing bolts and a parts store nyloc nut to hold the spindle in place. Then onto a drill press and drilled the other 3 holes through the factory knuckle holes

Quick wire brush of the knuckle and a skiff of black paint

Ford stub axle cleaned with new spindle seal installed

The Ford and dodge axle u joints are the same, so I removed the dodge stub shaft and reassembled the u joint with the Ford stub shaft

Antiseize is your friend here don’t be afraid to use it liberally on the knuckle to spindle area. Even if you look like tin man from wizard of oz when your done, if you ever have to take it off again you will be thankfull

Here you can see the one hole that was enlarged on the spindle

Slather the puppy up with the good stuff, pack some grease into the roller bearing inside and it’s ready to bolt down

Part number for the wheel bearing socket, kinda handy to know before you stomp off into the junkyard I think

Ford this conversion you will need 1978-79 ford f250 rotors. These I bought new. The wheel studs are the same diameter and length and the new rotor can be pressed right onto the newer hub. This allows you to maintain all factory dodge calipers and brake pads on the front. Grease up the inner wheel bearing drop it in and tap in the spindle seal to the back so the hub assembly can now slide onto the spindle

Once the hub assembly is on, insert outer wheel bearing, inner lock nut gets torqued to spec, outer lock ring and outer lock nut torqued down. Axle snap ring can now go on if you need to I didn’t put mine on. Also I didn’t put the dust shield back on (it was rotted away to nothing)

Hub selector assembly drops on and caliper assembly with some new pads to match the new rotors. Ta-da! Serviceable cheap and easy to get parts for free wheel hub conversion.

My cost

42$ per side at local wrecking yards for hub, rotor, bearings,seals,spindle,stub axle, hub selector

Parts store rotors, 38$ a piece

Parts store brake pads, 17$

One weekend of time with minimal tools, 16$ ( covered the beer I drank while doing the work)

Total cost 193$. Less then the cost of a single unit bearing!

Aftermarket free spin kits like these range 1600-2500$. That’s beyond my price range and this works great. I have about 35000 miles so far with no issues. This method works best for non abs trucks, and my truck had a abs delete program  but as long as you don’t have a abs sensor in the wheel bearing this will work. Enjoy the junkyard free spin kit! For us woodgassers this should be extra helpful as now you will have selectable hubs and reduced drag on the drive train (factory, the front axles shafts spin full time since there is no hub selector, Increasing wear speed a whole hell of a lot) for more fuel efficiency

but as long as you don’t have a abs sensor in the wheel bearing this will work. Enjoy the junkyard free spin kit! For us woodgassers this should be extra helpful as now you will have selectable hubs and reduced drag on the drive train (factory, the front axles shafts spin full time since there is no hub selector, Increasing wear speed a whole hell of a lot) for more fuel efficiency  my v-10 gained about a mile per gallon with this upgrade

my v-10 gained about a mile per gallon with this upgrade

For referenc here is a factory bought free spin kit in another dodge axle this one is abs for a 2001 cummins diesel truck my coworker owns that were are rebuilding. This kit was bought by the previose owner of the truck at 1600$

Same exact design but with abs sensor put in

Really excellent and clear procedure description and pictures Marcus. I doubt I’ll ever have to do it. My truck never leaves the property now but it’s good to know what’s what if I ever have a problem. Kind of surprised the junk yard let you scavenge a good axle. Look up the price of a set of Dana 60’s some time.

That axle in particular was bent so it was a part out. But it’s handy that the dana 50 parts are the same those trucks are all over the place. If that axle had not been bent I would have bought it complete for the 1200 they wanted just to swap it into my dad’s f250. Iv replaced more ball joints on that truck since he lifted it then I have changed oil in it. The ttb setup has it perks, but man oh man does it wreck ball joints when it’s lifted, run hard and towes trailers offroad

This is excellent information. I have a few heavy trucks but, nothing with sealed bearings. I wouldn’t have them. My 1 ton Dodge has a 70 axle with the big ball trunions instead of the ball joints. Same for my C-50 NAPCO and my F-900 Ford Marmon Herrington.

Nobody seems to service their front bearings often enough so, the manufacturers went to sealed bearings that are next to useless. I also use stock (offset) wheels. My '92 12 valve is 2 wd so, it has normal bearings. No junk for me.