Hi Don.

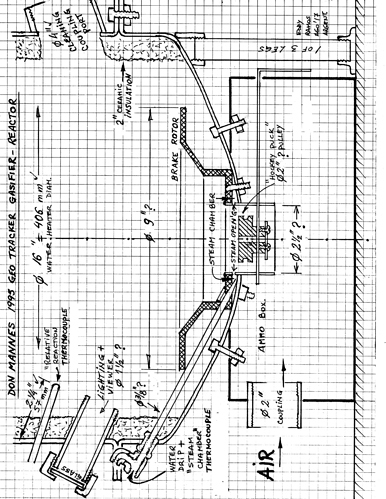

Thank you very much Don. I really appreciate your answer. I misunderstood your post 52, were you said: “I have 2 thermocouples installed. One is 4 or 5 inches above the nozzle and it penetrates the reactor shell about 2-1/4 inches with 8 inches being dead center, so assumed that the water heater tank was 20” diammeter. With a photo I took on your video, I based all my inner dimension on that diammeter. So I will adjust it accordingly, and post a corrected Reactor drawing.

Thank’s again.

Truly yours.

Eddy

Eddy; Fantastic report on Don’s charcoal gasifier. They say a picture is worth a 1000 words. In this case your pictures are worth 281 posts. I am a visual person, so I have tried on several occasions to put what I think people have said into a picture— none was ever as well done and explicit as yours. I know this charcoal gasifier has some particular interest for you, but I would ask that anytime someone verbally describes something that you find a little hard to understand, if you made a sketch of it like this is would help the rest of us a lot. Good job. TomC

Hi Tom:

Thank’s for your kind words. I am also a visual person and I like to contribute to this forum that is why I did it. This is my 1 cent contribution.

Eddy

I also have to agree with what Tom said about a picture worth a 1000 words , its so good to be able to sum up a plan or an idea in a blink of the eye allowing your imagination to work over time before even taking it all in , now i can sit back and relax and take in the splendid work that you have provided us all with Eddy .

Thanks Don and Eddy

Dave

Thank’s Dave & Brian for your words.

As I explained on my post 281, I missundersood the water-heater inner diameter so I based some dimensions of my first drawing on a 20 1/2" water-heater diameter. When Don Mannes reviewed the drawings he stated that the real inner diameter of his water-heater was 16". So here I am posting a reviwed drawing base on this new data. I hope this will help anybody when building this type of gasifier.

Eddy.

Excellent suggestion Tom. I’ve been thinking the same for some time. Standard industrial practice is to work from drawings or blueprints, because it is the universal technical language. I have felt DOW has been scant on this aspect. It’s one thing to describe a build, and then the learning process and modifications, but a definitive construction plan is elemental. Just as in scientific publication, detailed documentation of process is required to allow replication of results.

I would like to see a concise summary of each thread, and detailed cross sectional drawings like that presented above for each thread, that wiĺl be the major step to advancing and spreading the sucesses described on this site.

Regards,

The drawings don’t have to be as detailed as this one of Don’s by Ramose; I have posted several drawings especially of Max’s ideas, because I truly think every piece of information he posts is important. Unfortunately, I have to study such posting for some time and sketch as I study. TomC

Not being snarky, Just have to say presenting a drawing may be worth the time spent, but that time must be accounted for. Also, I or someone else may not want to give out hard-won knowledge to just anyone skimming the site and mining data to post as their own work. This has to be an individual decision, when and where to post detailed drawings. Not everyone on the internet has unselfish motives. I would love to share most of my knowledge with 95% of members here. That includes all the regulars!

Can I like this more than once ?

For me it is time well spent. It is the difference between making the idea or theory understood or not. If you don’t care if people understand what you are posting, why waste time writing a post? TomC

I understand the sentiment about hard earned knowledge, it’s a common and age old one. It also stands in the way of progress. I believe that if people are posting here, all the side projects are public domain, being published by the makers’ own postings. Wayne started this with his personal genius, and deserves the pay wall as a small personal benefit.

The group of enthusiasts is small, as Steve U says, literally one in a million. In science or engineering full concise disclosure is the accepted standard so that solid progress can be made. I expect very few people will be taking up these ideas anyways, as long as petro is available. Mostly the information would serve for the advancement of members. Given that the information is already in the public arena, it isn’t patentable, so taking advantage of it would be on an individual scale.

I think the net effect would be to advance the art amongst the enthusiasts.

Also, the best defense against others claiming intellectual right to creative works is to publish it first, end of controversy.

Regarding precision of drawings, I feel accuracy is key, small differences in dimensions can cause very different results. Besides, it’s far easier to read a dimensioned, cross sectional drawing. Precise drawings will also be an invaluable resource for figuring out design parameters when coupled with operational characteristics. As is known even with the Imbert tables, and near 100 years of experiments, sometimes it’s still more witchcraft than science and design. Every successful working independent design is a wealth of information that advances group knowledge.

As a compromise, perhaps members would be more comfortable if precise final drawings and performance characteristics were kept behind the pay wall?

Regards,

I support this Idea.

In keeping with this also, I encourage caution when submitting drawings of someone else innovation. Perhaps asking their permission before posting?

The phase " casting your pearls before swine" comes to mind.

Garry and Andy, and a good way to help support Wayne.

One “woodgas” concern with fully replicate-able dimensional drawings that I see:

Replication to be able to get the same results mean ALL FACTORS MUST REMAIN THE SAME.

This is one of the core basis for the much vaunted scientific method.

Woodgasing is really more (I actually hate to say this) more an art/skill.

Examples.

A authorized European factory was commissioned and built up, proofed in, and sent a gasifier engine fueling system to South America.

It would not work correctly.

Problem?

It was proofed in with European beech wood. The South American fuel wood trees were not beech. Not even close. The European Imbert factory offered to send a technician down to the client in South America. Or, have client ship back the system with tons/cubic meters of the intended wood.

Nope. Client had an artificer(cut&fit, jack-of-all-trades) friend who sorted it out, Jiggered/tuning-in the jet nozzles, tuned in a completely different grate configuration.

The same thing happen with dialed-in designs for sea-leval then tried to use “mile-high”, 2000 meters+.

American SW arid tuned then down into swamp-land Louisiana.

A central continental cold-dry air tune then out in my neck of the temperate far-west rainforest maritine.

A must-be as compact and light as possible mobile system pressed into service as a still-air stationary. Gee. No road travel shaking. No natural air flow cooling.

A perfected stationary gasifier system with a fragil cast hot glowing ceramic, or other core now rough road shaken. THIS Has happened.

A “perfect” caldo-rod-tube filtering array now mobile gone from protected garage-warm air to sub freezing cold air thermal shocking with most of the rod tube shattering. This HAS happened too.

Systems makers names withheld for social grace.

“One size fits-all hat solutions will fit most poorly.”

tree-farmer Steve Unruh

Yup so true Steve, every gasifier has to be turned up after it has been built, or change in fuel, location, climate, or operator, my was no exception and I am still working on the operator tuning part. The other 75%, maybe less now.

Hoping for some new up dates on Don’s Geo Tracker Project. When he gets some time.

Just can’t get enough from everyones projects, so much to learn from all DOW members thread sites.

Forever learning DOW Member.

Bob

Good points all round Steve. Fuel, use, climate and application being very significant. But documented builds I feel still provide the best starting info. With enough cases to examine design generalizations, empirical rules and best practices in design should begin to emerge. The approach is the same as engineers will often do, to consider proven examples then branch out. I feel especially the independent derived designs that eventually are made to work well are a wealth of knowledge.

Agreed. But really the information is already there in many build threads as Ramos has demonstrated. If chosen to document behind the pay wall, certainly that is proper etiquette.

More art than skill is so true. On a recent road trip, the wife and I listened to the latest audio book about the Wright brothers. Why were they radically more successful than others? Because of their skill, yes, but even more so because of their insight into, and practice of the art of flying. Lots of testing and experiment to produce a great machine, then hundreds of hours to get an artistic feel in the body for the art of flying. So, where other’s machines and performances were herky-jerky, the Wright’s first public demonstration in Europe was flawlessly beautiful and set off a wildfire of over-the-top publicity and acclaim.

I think their conception, design and use of a wind tunnel was possibly their greatest advantage, It allowed them to analytically work out aerodynamic problems at the heart of the problens of flight, particularly the first conception of an airfoil shape.

Perhaps that’s the lesson for us to reflect on, their competitors weren’t succeeding by taking on complex problems by feel and intuition, while the Wrights analyzed and engineered solutions.

The Wright brothers were not the first to use an airfoil, but their extensive wind tunnel experiments led to moving the top of the airfoil arc closer to the lead edge for greater stability. Hence, the Wright airfoil looks much more like the shape we now take for granted. This is old news for me. What was new to me in the book was how Wilbur’s experience as a gymnast and his understanding of how we learn to ride a bicycle led to his concentration on training the body for the subjective, nuanced and automatic responses to wind currents that he had observed in birds on the wing. Being an engineer by temperament, I share Steve’s reluctance to acknowledge the art/skill side of what we do, but that is a reality we face everywhere we find excellence. My daily challenge is getting my hard-headed tech side to have a respectful conversation with my art/skill side.

To maybe reel this back to Don’s Geo Tracker, Don’s work appeals to my art side as well as my science side. I look forward to more great stuff from Don. I’m glad he is willing to share.

I too appreciate the desire to protect intellectual property. Many do not realize that the purpose of patents is not to hide things from others, but to allow safe disclosure so that the “art” might move forward.