Congratulations Don, We need to have you for a “main event” speaker on Saturday @ Argos.

He won’t need to pop wheelies to get attention this year.

Never forget as much as Don’t wants us to

Hey Don, this place is rather close to you. The novelty of your clever set up would probably give you a free analysis.

Thanks for the tip Doug.

hi Thierry,

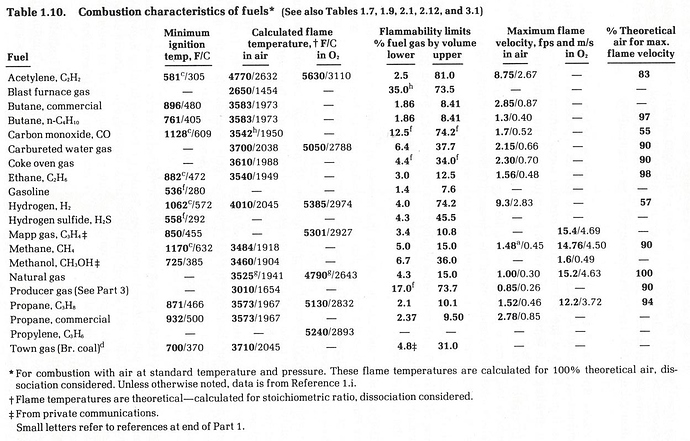

Based on the example below, if the mixtures changes, the temperature changes…

also interesting  http://webserver.dmt.upm.es/~isidoro/bk3/c15/Combustion%20characteristics.pdf

http://webserver.dmt.upm.es/~isidoro/bk3/c15/Combustion%20characteristics.pdf

So if one can weld with propane, according to this chart of temperatures, wood gas should be hot enough to cut steel and weld with it too?

I know a guy that used to weld and cut with woodgas so its possible.

Hi Bill,

by my own experience  the correct mixture and richness of your gas, will allow you to do some real damage to metal…

the correct mixture and richness of your gas, will allow you to do some real damage to metal…

being able to do fine art welding ?? who knows… there are many artist in the world that can weld, not all of them can make good gas

melting is fun…

But to stay on topic: The flame temperature you can reach with your gas, is an indicator how rich your gas really is…

Don,

Your good work has really fired up the conversation. What a great build!

When you do get thermocouples installed I would be interested to know the reaction temp during flare before starting the engine and the corresponding inches of water column reading for the reactor vessel.

Because of other family car repairs my MGB project has slowed to a crawl.

Koen,

I can guess what you offer.

But technically how to associate the temperature of a flame has a gas purity%

Thank you, Thierry

Thanks Bruce,

I have 2 thermocouples installed. One is 4 or 5 inches above the nozzle and it penetrates the reactor shell about 2-1/4 inches with 8 inches being dead center. At start up it reads about 220 F when the first little gas ignites at the flare but won’t stay lit. It does stay lit when the temp reads about 350 F. If I remember correctly gas starts to generate at about 1270 F which means it has to be that temp near the center for that first little gas to ignite. This shows how good an insulator charcoal is. The piping, cooling tanks and filter barrel all have to be purged of air which might make the gas weak at first. After running for 10 minutes or so the temp gets around 1000 to 1100 F. The second thermocouple is inside the water drip tube that goes under the rotor. This temp stays around 200 to 250 F as long as the water is dripping in but at shut down it rises to 350 to 400 F.

Since this reactor is updraft and the char bed is over 2 feet thick I questioned the necessity of vacuum readings so I never paid much attention to it like I did on the wood gassifier, but now you are making me think that it would definitely have an effect on temperatures in relation to the amount of air/pressure drop going through it.

I am still in the early stages of sorting this all out so stay tuned.

Don,

Thanks so much for this good reply. I’m also trying to sort things out. My rig has a deflator/inflator blower controlled by a PWM. I’m hoping that i can find a vacuum setting for flaring that will allow the reaction zone to produce good gas without going critical and chewing up my nozzle before the engine starts and the EGR is in the loop for reaction cooling. I’m hoping that watching the thermocouple and vacuum gauge will help me find a PWM setting in this safe sweet spot.

I’ve had this untested hypothesis that a lot of nozzle damage occurs during the flaring stage before the engine starts and things stabilize with water drip or EGR.

The danger is greater in my case because the deflator is much more powerful than a bilge blower. My plan is to set the fan to draw 5 inches of water column then carefully watch the reaction temperature to find a reaction temp between 900-1000C.

The dream is to transition smoothly to engine running without blasting past this target temp.

If I add a water mister then there will be an interplay between EGR and water to keep things stable. I’m thinking of using a micro switch to close the EGR and add water mist only when throttle is open more than 2/3.

I was so busy lately with life that I did not have much time to try out my charcoal Tracker so last night just before dark I went for a ride. I forgot about my cap cam until about 7 miles into the ride and as you will see I need some practice in aiming it properly. One thing I noticed after shutting down and putting it away is that I did not smell like wood smoke! It used to be that no matter how careful I was starting up and loading with wood and curiously looking in the hopper after shut down (which I shouldn’t do) I always came away with that familiar smokey odor. You don’t get that with charcoal. Start up is very fast and could be immediate - light up and go - and let the engine on gasoline pull a short time on the gasifier. I was always too chicken to do that on wood but I know it has been done. Temps kept climbing the whole time up to a little over 1300 F. but I need to ride longer to see when that levels off. As long as air is entering the nozzle area the temps there stay below 280 F but climb to 4 - 500 F at shut down. These are relative temps because they are near but not in the wicked high temp zone.

Hey Don ,

Thanks for the ride !!! You make us all smile .

You got me very lost but you were a champ finding your way back home

Great ride Don, listen to that baby wind up! look forward to seeing it in person next week.

Are you sure you had the gas off? That drives like a racecar. What do you think the "Oh No!’ Temperature is?

Impressive Don!

Thanks for the video Don!

What kind of charcoal mileage are you getting?

That is when I look back there and see a pile of molten metal.

That really runs nice, pulls hard thur the gears!! Sounds great! Is the “hatcam” handmade I phone holder??