Ive never looked at that PDF but that looks nothing short of an Imbert. What makes this special?

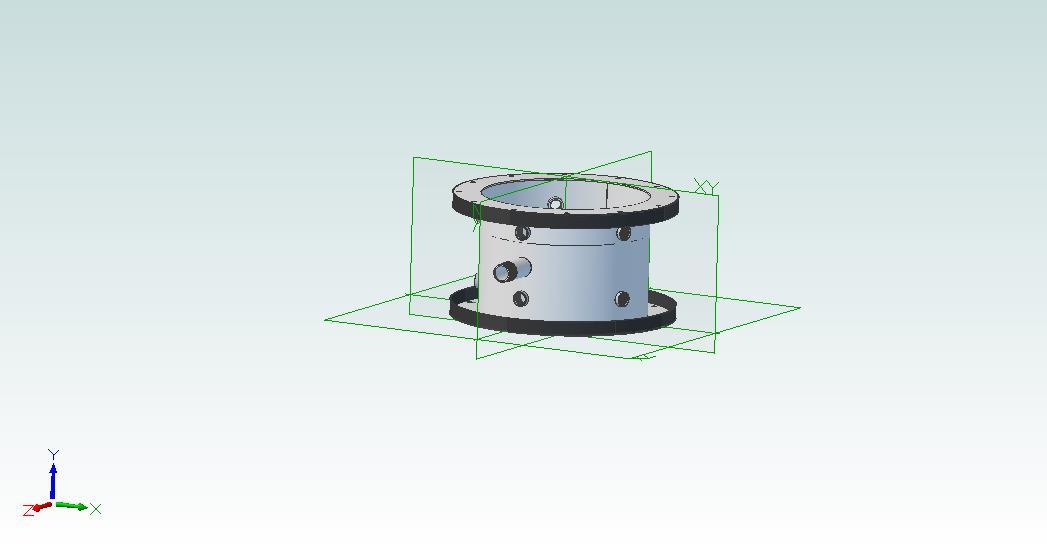

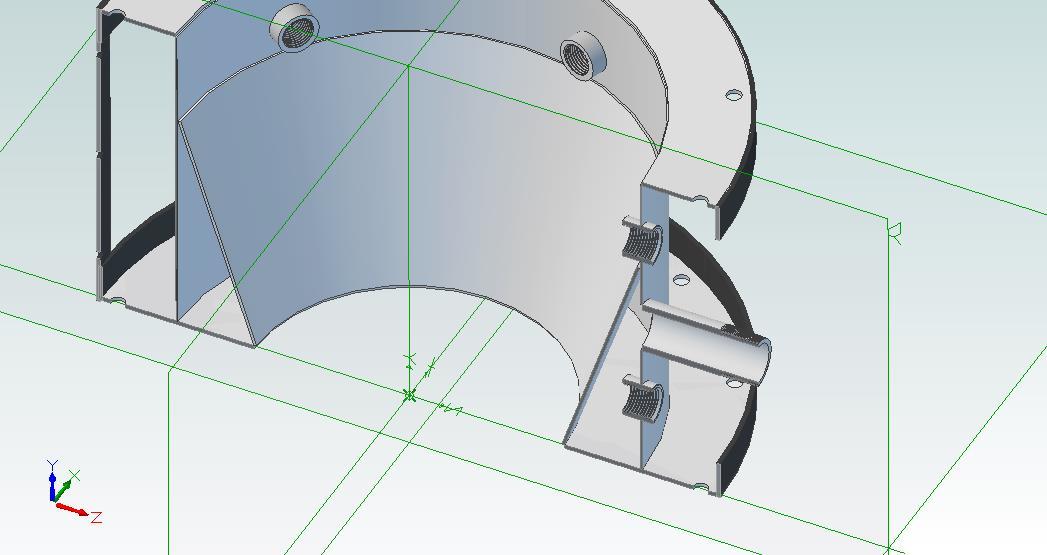

The grate is similar to ours where we are rotating it on a shaft radially.

We have built very elaborate air preheats and went to simpler designs you can only heat the air up so much, and it heats up very fast. We now have a simpler baffling system and are getting the same results as before. Where we differ from any one else is our reduction system. Our reduction is now fours times the spec on the imbert chart with a hybrid cross draft grate. Our jetting is tuned slightly to match the fuels we specifically test with. The Imbert chart is just for reference, no fuels run the same pine vs hardwood vs other softer woods. Chip size, moisture, air preheating, and other aspects play a whole other part in your tuning.

To get fuels to flow in any small gasifier grate flow vs your upper raw fuels flow must match. Adding the grate and hopper agitators will correct these things and get your machine to flow. However, it must be tuned as well. The better tuned the machine the better the agitator will work.

We did try creating the void very early on to stop bridging. This was the very first rev of what was the Evolution design at the time and why we had the bump out in the mid section. It didnt seem to make a difference and I wanted to try different designs. So we kept this bump out to create other designs and this has evolved into what you see today, its now there to simply make room for our jet system and to allow a place to add insulation.

Our conical / tapered hearth is also tuned for flows at combustion. This combined with our reduction bell is sort of like the hour glass hearth systems, but we are retaining the void around the reduction bell for natural insulation build up. From here our bell also has a tapered top and is also shaped like an hour glass, its no longer an inverted cone. The side walls of our reduction have revisions for carbon build up along the outer perimeter, the lower portion then transitions from down draft to cross draft to eliminate packing, The grate design and agitator are also components needed for this work.

Pull your gas out from the side like a cyclone in reverse. This does two things, it helps distribute heat evenly while also aiding in dropping your heavy debris. Our new system with tank we hardly even need the centrifugal filter any more and this may go away in the future.

So I guess at the end of the day for a gasifier to flow, we need to consider fuel first, then design around it. Denser fuels need less reduction then less denser fuels, smaller fuels need less great spacing. A dense fuel like a wood pellets need longer jetting, jet openings typically are smaller as well. But you can always open them up. Pellets will flow well going into the combustion zone but are more prone to grate clogging. Chipped fuels are less dense so all the above are just the opposite, however, if a hopper agitator is used this will eventually effect things down stream.