Search “kaowool”. You will be busy all day.

Hi Jan,

I like the linear defined path of the burner, cyclone and filter. However, I would

like to see the interior setup in the burner unit. My concern is the

air feed being so low on the unit and burning a lot of the produced gas

right there and sending the rest to the filter. Check out the imbert

sectional pics for the layout (air feed top down through the fuel) and

you’ll see what I mean.

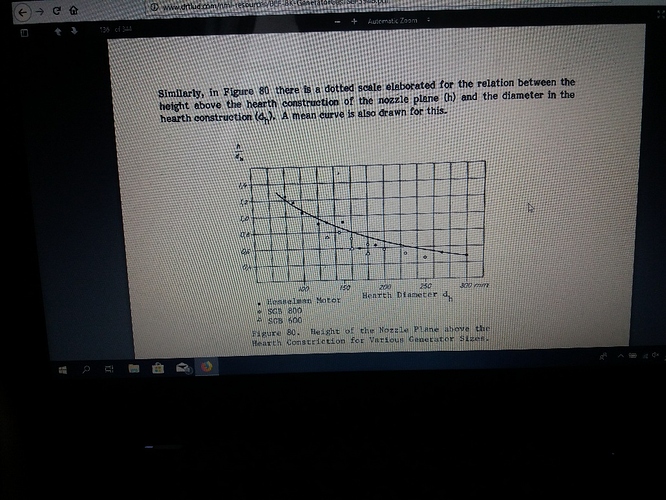

Dimensioning to load is important. It shouldn’t be a difficult change.

Hi “Pepe”, do not know if I understood you correctly (is a little bad in English), did you mean that the nozzles are too close to the hearth?

Pages 21 and 28 show how it looks inside.

Hi Jan,

It’s a little hard to accurately tell from the top down view

what the separation distances are between components.

There are HP driven dimensions for these separations.

Most important is the top air feed drawing air down through

the unit. Check out the imbert specs chart for these.

I definitely don’t like your present air intake location.

I think you’ll find the change worth the effort.

Pepe

Disappointed, put things together to test today, first it was nice smoke after the cooler, then there were some puffs in the gas unit.

Then nothing worked, almost no smoke at all.

Cleaned the whole unit, no errors, at the end I came to think of the fiberglass filter, seemed to be completely dense and very wet.

Removed this and tried again, very nice flame immediately, it was not visibly that it burned.

Run for 2-3 minutes then the fan broke.

Congratulations on the flare!

What kind of fan did you use?

Tack

Car vacuum cleaner

The fan I use for doing blacksmithing as a overheating protection so it will die if getting too hot, but work again when it have cooled down.

No idea if vacuum cleaners have this, but maybe it only needs to cool down?

Jan, I think to use a filter like that the gas has to stay well above dew point at all times. Preferably run the fan and flare off prior to the filter, or bypass the filter until the gasifier is up to temp.

With all the moisture in woodgas any fabric will probably clog if exposed to condensation.

Congratulations to your flare.

Hate to be the barer of bad news, but I think all the moisture and stuff that plugged your fiberglass up the first time probably made it’s way to the fan motor after the fg was removed. Two of my early builds where I was using the engine to pull on the gasifier, the soot and moistur (with tar) made it throug my cyclone, cooler, hay filter , through my pipe over the roof and down into the engine. Broken push rods and stuck engine. TomC

What are you doing to avoid this now?

It’s my biggest dilemma too, afraid to ruin the engine.

Jan,

Do you have an older engine that could be used as a test? Like a worn-out flat-head lawn mower engine or something? Once you have an acceptable flare, you won’t need the fan anymore and the filter may not get clogged so fast.

post with drawn by auther.

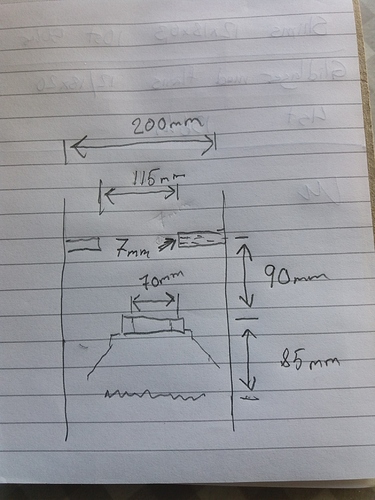

What size engine are you running again? Im going to to assume you are running a smaller engine 400 cc range? Are running a hopper shaker/ vibrator?

For this size engine you should have a restriction of around 50mm your height it fine. If you are not running a hopper shaker you are probably have issues with flows. Both these things are playing into your tar production. Once you have flows established and are sized right the tar and moisture will go away.

This is if you are running good fuel as well. I dont know what you are running but if you are running ships 25mm x 25mm x 10mm thick than this should be good fuel. But it needs to be dry, if you feel any moisture just holding it in your hand, it no good and needs further drying.

To be truthfull- I built another gasifier and followed the recommended dimensions from Imbert tables for the engine I knew was going to be using. I sat both gasifier up in my shop and put a 20 ft piece of 2 1/2 pipe up to them. Hooded my Kirby on the end of each pipe and started trying for flares. The newer build ran much hotter at the end of the 20 ft pipe. I figured the hotter the gas, the less tar that can get through. I put that one in my truck and started building a cyclone, cooling rails and a hay filter. That one has run tar free. TomC

Tom,

Nice confirmation on building to the imbert numbers ala HP.

I like experimenting, too, but build one to the numbers so you

start out with a tried and true working gasifier. It’ll improve your

day, believe me! Pepe

I tested a bit today on the unit, tried to find leaks, see that the lid of the unit is leaking quite a lot.

Is that why I don’t get any combustible gas now?

Jan, I think the lid would have to leak a lot (visible gap) to cause the gas not to burn. As long as you have a good vacuum in the hopper, nozzles will blow enough to keep the heat up. It’s my experience if the hopper starts to sneeze repetedly (like once a minute) you have too much of a leak.

Weak gas is most likely caused by a coarse charbed or air leaking in somewhere downstream the grate to burn your gas prematurely.