I hear your frustration. I went back through this thread and first I would request pictures of how all those parts went to gather in the truck.

Looking at the parts that you built and have shown, I would particularly ask "how you mounted that air/gas mixer to the engine. I spent a lot of time looking for lack of power and having to run with the air valve to the air mixer full closed. I was feeding the air/gas into the stock air cleaner. It turned out the stock air cleaner did not sit on the throttle body tight. At idle the leak killed the gas and at speed it diluted it. There was a rubber gasket on the bottom of the air cleaner but I ended up putting silicon over the rubber and also silicon ed the top of the air cleaner.

If you have some place that you can disconnect the pipes going to the gas/air mixer— try running the engine on petro ; close the air valve to the air mixer, then where you disconnected the gas pipe, plug the part of the pipe going to the gas/air mixer. With a good seal-- the engine should stall almost immediately from a lack of air. If it runs at all, you have an air leak in the area of the air mixer and carbruator/ injectors/ TB. TomC

Thierry,

As you can see, we are hungry for pictures of the arrangement of your nice looking components. Great advice from Tom. The top three causes for gasifier failures are:

- air leaks, 2) air leaks and 3) air leaks. My first charcoal gasifier vehicle was a Toyota pickup with a 22R engine, so I am especially eager for you to succeed.

Just in case you don’t already have the Pederick manual. I thought the trouble shooting methods were good.

Rindert

here are some pictures of the setup

truck seen from behind (a platform will be installed on the back)

!air restriction valve (downstream of the flowmeter)

switch and PWM of the fuel pump

starter pump between the gasifier and the oil bath filter

the charcoal I’m using

thank you for your help to all. Feel free to ask me questions if it’s not clear

Hi Thierry , Koen was correct in saying only adjust or alter one thing at a time , so once you have seen and read all advice or suggestions it might be a good idea to list them in order of doable with ease , if it was me i would first start blowing air into the air inlet pipe on the gasifier while connected to the engine and then with a spray bottle of soapy water start on the gasifier and then go over all pipe work and connections all the way up to the engine bay , if no leaks are detected at all then move onto restrictions that may be causing it to starve of fuel .

You mentioned earlier in the post that your engine was “hunting” revs increasing and decreasing on there own , well if that was running on petrol i would immediately go to the carb and fuel line to check if fuel was flowing to the carb and then check the jets for blockages same with charcoal gas , if the engine is starving of charcoal gas it will do the same thing , at least it has done on one of my small engines a few times .

If no faults so far found i would then look at changing the Nozzle size and test , if better but not still correctly running then look at the pipe work size make sure its allowing the engine to breath in all the gas it needs .

The last thing i have come across is the tap on your air pump the pvc tap i once used always leaked air or sucked in air even when fully closed off so with the tap turned off to the fan please make sure to spay plenty of soapy water around the fan when you pressurize the system to check for leaks .

Fingers crossed Dave

Hello Trigaux.

Can you determine if the motor is running poorly because weak or lean gas or if it is running poorly because of a too rich of a mixture .

If running petrol and too rich there will be smoke out the exhaust . When running on woodgas you can richen the mix enough to kill the motor and there will be no smoke .

Hi Trigaux. did i read this correctly that your nozzle is 5/8" for a 2.5L engine? If so, that is TOOOO small. I’d recommend at least a 1.25" nozzle. You are looking for restrictions that limit the amount of chargas you make in your system. If your engine can pull more chargas than the nozzle can create, you have a restriction. Within reason, it is better to have your nozzle too big than too small.

Your charcoal size looks good. Air leaks are a definite bug a boo so pay attention to those too.

I’d also recommend keeping an iron pipe between the gasifier and the cyclone. If you run the charcoal bed too low, that cyclone will get really hot. Hot enough to burn paint. If you use a silcone hose, it will act as a safety valve but will need replaced if it gets cooked off.

My 2 cents worth

Gary in PA

Thanks Dave, the engine of this truck works perfectly well with gasoline. it is only with charcoal gas that problems arise

I will check the tightness of the gas line as soon as possible

thank you for your advice Wayne they are very appreciated

I thought to install a display “afr” to follow in real time, the richness of the air / gas mixture

Thank you, Mr. Gilmore

the entire gas line is 2 ", the only restriction is the 5/8 nozzle

I can easily drill the 1 “nozzle (this nozzle is made, currently, from a 1” pipe shrunk to 5/8)

Thierry

Does your gas burn on its own? For good engine gas, it has to ignite with a spark and burn with a roar.

I wuld first check for leaks, then drill the nozzle then replace the char with dry one.

Whats the diameter of your air valve? On my 2.3l Mercedes l have a 3/4" ball valve. Usualy a bit closed. Thats to give you a idea of how small of a opening is neaded to run a engine this size.

Thierry,

Now that you have all of these great guys on your trouble shooting team, success is assured. I’m confident that you will be smiling soon. By helping you, this Dream Team has just created a great trouble shooting guide for the rest of us. We are all pulling for you.

YYYYes I smile now, thank you all for your support.

I just came to roll the truck at all engine speed. It worked perfectly, even better than with gasoline. The engine purred both at low revolution and at full speed . I did not need to hybridize to gasoline in the climb the engine was strong .It was Tom and Chritijan who guessed the problem.

I had an air inlet on the pipe of my restriction valve . I could not adjust the air / gas ratio

I temporarily installed a pipe and an adjustment valve and everything worked. I need to install a new adjustment valve upstream of the flowmeter so that it can, again, run on gasoline or chargas or in hybrid mode .

All this is very exciting. I’ll keep you informed ![]()

Thierry

The price of lemons is going to go up.

for you to visualize better what I did temporarily

the gray pipe leads the air to the mixer, the black valve of the new restriction

the flowmeter on the right

And in the center the old restriction valve that needs to be changed

Kristijan. Do you renew every day coal from your gasifier (like Koen) for easy ignition with fresh coal?

I can not re-ignite my coal and produce gas that burns alone the next day

I empty my gasifier and recharge fresh coal every time I start it .

do you have another solution?

I use a very large gasifier tank a 205 litre drum with a vertical nozzle from below and i suffer from harder than normal starting once fresh charcoal has been run once , what i found best for quicker lighting was to do what the wood gassers do and before lighting poke through the charcoal around the nozzle area and break up some of the charcoal and clinkers that are around the area of the nozzle , and i also poke a allthread bar up through the nozzle as well , and i find that helps a lot to get fresher charcoal reacting .

Dave

Thierry,

Congratulations! We look forward to hearing how other tweaks (water drip, EGR, timing advance and increasing nozzle size) affect your system performance.

On the issue of starting up with used charcoal, poking through my nozzle is usually enough. If I want to be sure, I use a small screw type earth anchor to spiral down to the bottom and lift the old charcoal away from the nozzle then I use Kristijan’s pointed and perforated vacuum nozzle to suck out ash and dust from the loosened charcoal. Although I haven’t tried this yet, it has been reported that using your blower/fan to suck some fresh little pieces through your nozzle will do the trick.

although I sealed the air line as well as possible

I can not adjust the air / gas ratio with my butterfly valve cituated upstream of

flowmeter.

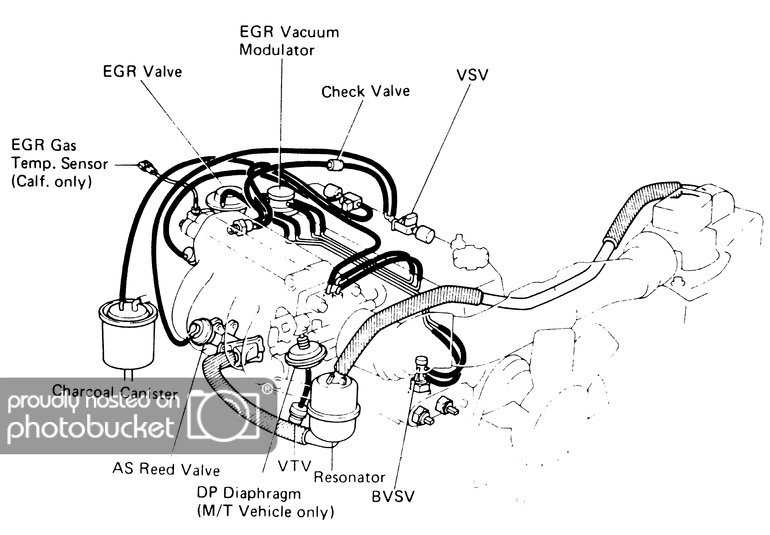

Do you believe that the hose that comes from the resonator and between the air filter and the flowmeter could de-adjust the valve

Thierry

Thierry,

Any hose bypassing your valve will offset the air-mix. Try see to that your valve has the same conditions as your flowmeter.

Has anyone ever tried this kind of pressure sensor to measure the differential pressure of gas and air at the mixer?

the sensitivity of this kind of probe is it accurate enough to manually adjust the air restriction valve?

Thierry

Hi

I am looking for information to build a safety filter to complete the gasification plant on my truck. I read that wire cloth filters were recommended. Does anyone have information on this subject?

Thierry