Hi Steve,

No the remarks i made above was concerning a video that Ray pointed out to me at an earlier post and a mentioning about “FlashUSA001” again in his last comment.

So the remarks above, have been my remarks about the video from “FlashUSA001” on youtube. My remarks, my responsibility and if proven wrong; mea culpa

Comments given and taken making me learn. ( most of the time i learn about the comment giver ) Keeping quit also disables the listening capacity’s, ergo the learning ability.

If a teacher wants to be sure the students are really learning and paying attention, he should make some errors to provoke their attention

( learned that in the service )

I am in the middle of my life and in the middle of learning from DOW and teaching myself , so half way all the way…

Learning by my mistakes, in transition from being a student to be a teacher, but always straight forward on the path of improvement ( mostly my own improvement “chuckle” )

Any how… main purpose: showing the world that DOW is an excellent idea and change the disbelievers minds.

Therefore i use marketing words as “Green Waste Charcoal” , “Carbon dioxide converter”, “Using Carbon dioxide as fuel”

One member of the “R&D team Renewable Energy Thailand” is besides a Nr1 Web marketing specialist in Australia, also a engineer Chemical and applied science.

I would be honored if you and some other people from DOW would lend their names also to the list of “R&D team Renewable Energy Thailand”.

You’ll have the valued knowledge and deserve the credits…

Nice anekdote:

This week i had a debate with some professor. He refused to believe that i could convert Carbon dioxide into energy. He “proved” his point with showing an article about gasification… I that article, which he pointed out, was clearly stated that C + Co2 + Heat = 2Co, also Co2 + H2 + Catalyst = CH4 + H2o…

What do you think he did not understand ?

Back to topic; R&D gasifiers

1.About the Brandt idea of doing things… first with words, later with drawings, followed by the deed… ( always my favorite part )

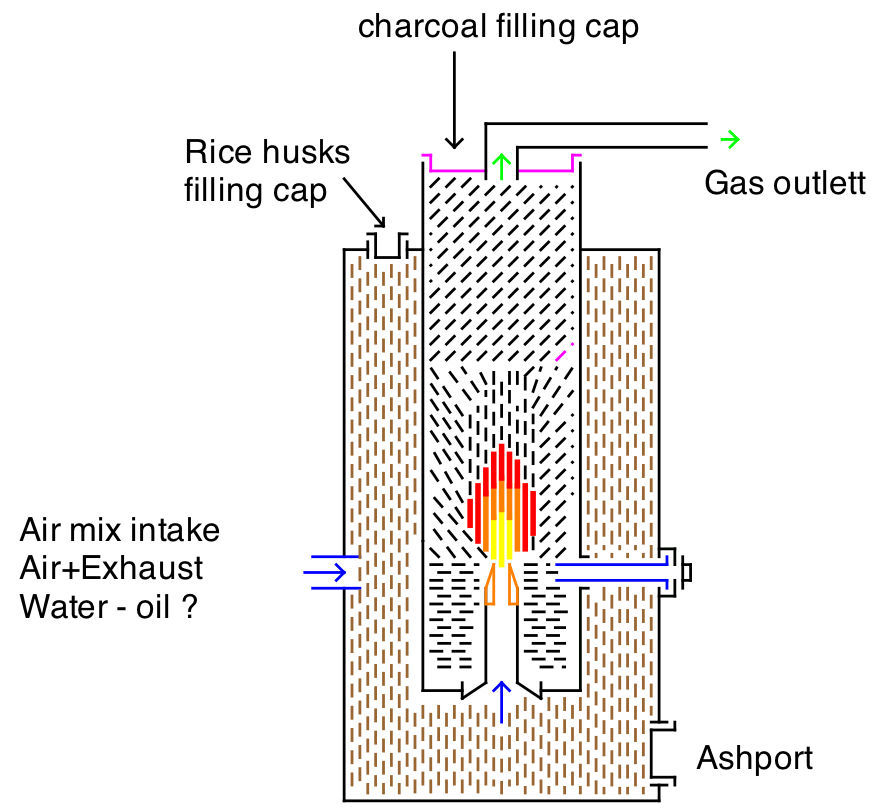

imagine my gasifier with an Brandt style outer shell , space between outer shell and my gasifier filled with rice husks. so instead of spraying water on the outside of my gasifier, its rice husks leaning on the hot metal from my gasifier. The rice husk will be charred by the heat of the hot metal ( indirect )

The fumes from the rice husks will then be sucked into the air nozzle from the gasifier. ( also can be oil soaked, imagine what possibility’s )

- imagine exhaust gasses passing also through the feedstock from a gasifier, using the heat from the exhaust to rise the temperature, leaving a part of the pollution from the flue gasses in the feedstock to be converted in the gasifier. ( soot is a good fuel )

Give me your idea’s, it will keep your mind of woodstock ( joke )

I will draw a sketch for those who wants to participate in the R&D with their appriciated comments, give me a few hours dough…

Regards

Koen