Joep, what an old man, it seems to me that you have only just begun to live, you do not have a single gray hair, you have barely come out of tahuda puberty (I could not say that for Jo).

I’m not counting on power yet, I have to take a test first, Kamil is a good help to me, he doesn’t fall for any "siphoning"

Haha,

Tone, we can’t do much about age and gray hair. It is what it is. Btw, I saw a gray bearded man running a compressor yesterday. I wonder who that beard belong to?

I have to ask you again - if you’re cooling off 90% of 10 kW to condence your medium - what kind of heat need does your floor heating have? A normal house would maybe need 2-4 kW continius heating during cold winter months. You would need a pretty good flow rate and heat need to cool down 9 kW continius, with the floor heating alone.

If I remeber right you have a storage tank connected to your boiler. With it’s stratification you should have “unlimited” supply of cooling ability, if the cooling heatex was fed from the tank’s cool bottom and the water returned back to about the middle of it when heated up.

Hi Tone,

From your projected below 10% conversion to mechanical? energy numbers you are now into best-case current Thermal-Electronic-Generator cells range.

3-4 different technologies on these.

Thier conversion efficiencies and durability’s are slowly evolving upwards.

So far as brainiac-divorce driven . . . never ending; never good-enough, Alt-Energy fixations should be rated right up with alcohol abuse, street drugs and gambling addictions and abuse.

Steve Unruh.

Jo, hello, I know you know that I didn’t mean you about gray beards and hair, but about late puberty, or as my daughter tells me, middle-aged crises, maybe …

I have to admit that you are right when you state the power of underfloor heating, it probably doesn’t exceed 5 kW, but I also have radiators designed for low temperature. Yes, water is easy to play with, but I find it interesting to get some electricity from this game, you wrote nicely somewhere above "The beauty of this system is that it can work 24 hours a day, 7 days a week and is not dependent from the occasional heat of the flue gases ", the power produced will depend on the current heat consumed and on the heat difference. I must also admit to you that at the moment time does not allow me to realize, but it is good to have clear details of the project in my head, and maybe someone else will take up the challenge, …

LOL! So true!

It shouldn’t be funny I guess (since I resemble that remark), but thanks for the laugh

Excellent diagram, @Tone. Truly self explanatory. Make me thinking since morning.  So few new things arise.

So few new things arise.

Turbine work is almost isentropic, ns ≥ 95%. With your engine cartainly impossible. If you will get 85%, you will be our hero.

Cold side is OK. 13°C increase for 9 kW represent 10 l/min flow. Nothing strange for big enough floor. In winter

HEX volumes could be quite big. For such power flows and low mass flow, you will need good chunk of copper. Low temp HEX tend to be pretty inefficient. Are you ready for it?

Steam drum and deareator are missing in your schema. Donno how in low temp organic cycle, but normal Rankine doesn’t work without them. Droplets in turbine and bubles in compressor are killers of performance and engines as well.

@Tone , I’ve find a document on internet which might be of your interest. Unfortunately, it is pdf document, which is not authorized for upload. Finally I found working link to the publisher

You could save it to Google Docs, make the file shareable with a link and he could download it that way.

Kamil, thank you, lots of interesting reading for long evenings. Are you going to do something similar?

I don’t think so. At least not soon. Have no usage or utility for such mechanism. Maybe one day, if I design our new house, I will consider such thing. True experience would be welcome.

Hmm, obviously I’ll have to plow the wasteland, but first there’s a tractor, … I don’t have a real solution for the pump yet, maybe I could use a high pressure fuel pump from Mitsubishi GDI, for example, … but sealing is a problem. They tested different media in the document, somehow I think R-245fa is the most suitable, probably butane is also close to it, most of them are flammable substances, so we should not allow leaks.

Aren’t fuels pumps little bit powerfull for your purpose? Normal range is in hundreds of bar. What about some oil pumps used in hydraulics?

In your designed temp range R-245fa is most promisinsg, providing double efficiency against propane. Also flames are not in concern. But the price really is

For me, flamable gases are forbidden. I do water, electricity, simple constructions, welding, distillation, many other things. But I keep myself hundred miles away from gas.

I don’t want to try to talk you out of a project that you find fun, but the time and money you will invest here vs efficiency/energy return is going to be low. I’ve been down this rabbit-hole with thermal solar + heat engine.

Organic Rankine Cycle engines are just steam engines for low temperature heat sources. Hobby steam engines are low efficiency and that’s using high temperatures on the hot side. Hotter hot sides improve efficiency and increase theoretical efficiency limits, that’s just thermodynamics (give Carnot efficiency a “wiki”).

Hobby ORC, at those lower temps, is going to be very low efficiency. I was going to suggest looking at car/truck pumps and A/C equipment. It’s cheap and available, runs off low voltage DC. ORC engines are just just ACs run in reverse. Seeing that you already have that thought. And yes… I’d use propane/butane. It’ll be easy on the seals and low pressure which is good if you run higher temperatures and the seals get a little soft. I’d double check the max temp on your pump oil as well.

Quick edit/addition: Consider counter-flow heat exchangers to minimize the temperature difference between your heat source and your ORC system hot side. It’s more complexity but every degree counts when the hot-cold differential is so low. You’ll want a very effective cold sink as well for the same reason and as low temp as you can get.

Tone,

Maybe enough power to keep some LED nightlights on, or trickle charge a battery bank. Don’t waste too much time, but the fun can be in trying out something new! Put some more feathers in your headdress, so to speak!

Carnot can be a bummer.

Ideally you would reverse your system such that you generated power off the top of whatever was available and used the ‘waste’ heat for domestic uses.

I spent a few years on Rankine cycle systems, ‘high efficiency steam’, before leaning into gasification. Here’s a few piston operated valve uniflow steam engines I built (400F, 400psi max). Turns out steam is not simpler:)

https://youtu.be/MR1qV843awI

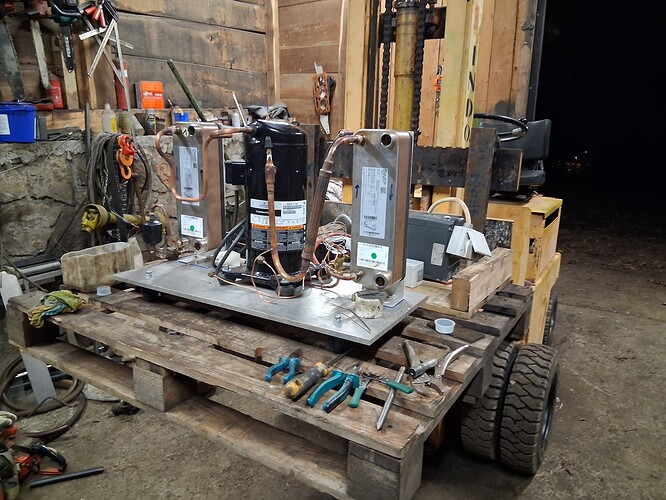

20 to 30 years ago I was involved in cooling systems and heat pumps, which were not yet widely available as a heating method, at that time I assembled quite a few systems at home and they are all still working today. An old friend and colleague asked me to assemble such a system for him, he lives by a stream and has a guaranteed source of heating. The heating mode will be 30/50 °C, thermal power approx. 20 kW, COP 4-5 (ratio between the electrical energy input and the useful thermal energy,… 1/4)

It is also necessary to install a protective switch to turn off when the pressure is too high or too low and a heating pump speed regulator, which works based on the condensation pressure,… the connections are ready,…

Very nice system Tone. Ecorenovators.com has some great forum threads on DIY heat pumps.

Heat Geeks is another crew (based out of the UK) to look up for HVAC efficiency and cleverness.

That said, Tone you seem to be full of cleverness! Impressive.

Seeing the two water to water flat plate heat exchangers in your picture. Ground source heat pumps are amazing assuming you have a good field or well set. Air source can be surprisingly good these days but nothing beats a ground field/wells pinned to 15C/60F.

Water-based heat exchange to the heat pump itself opens up a lot of possibilities. You can have smallish insulted hot and cold water tanks acting like thermal mass walls but better because you can control heat flow in and out. This isn’t for seasonal heat storage like a ground source field. This is for daily cycling like a trompe wall.

You’d use excess solar power during the day to heat or cool water for the night. That reduces heat pump energy use while on battery. The pipes will be short so they can be large diameter to reduce pumping losses. The heat or “coolth” doesn’t even need to come from the heat pump. You can use solar thermal panels, wood boilers, evaporative coolers, sky facing radiative panels, basically all kinds of no/low electricity heating and cooling but stored in tanks and dispatched through the heat pump system as needed.

Any heat energy cycling through these daily water tanks is energy you are not cycling through the seasonal ground source field/well and that allows for a smaller field. You might not even need a field depending the heating-days and thermal load of the building and your “passive” sources.

I ran some math and the tank would be on the order of several thousand gallons for 10c/20F temperature swings, regular sized and insulated house, area that sees sub-freezing temperatures in the winter. That isn’t small but wells aren’t cheap.

Hello Tone.

What refrigerant gas are you choosing to use in your systems?

S.U.

Thanks for the answers, the compressor is designed to operate on R407 gas, well, I have R22 in stock at home, which has similar pressure properties, I will probably fill the system with this gas. R22 has very good properties as a refrigerant gas, it is probably one of the best, but it is now banned for use.

Hydrocarbons like propane, butane and iso-butane are easy to get, non-ozone depleting and high performance. They are also explosive in the right conditions but used in plenty of consumer applications, especially in Europe. For a “tinkerer” without the licenses to buy the HFC type refrigerants… it’s not a bad option.